This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

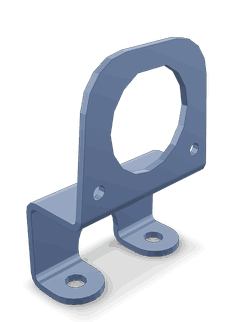

The Cummins 3964775 Wiring Retainer Bracket is a component designed to secure and organize wiring harnesses in commercial trucks. It plays a role in maintaining the integrity and efficiency of the truck’s electrical system by providing a structured environment for the wiring, ensuring that electrical connections remain secure and organized 1.

Purpose and Function

This part serves a role in the electrical system of a truck by securing and organizing wiring harnesses. It helps prevent wires from becoming tangled or damaged, which can lead to electrical faults. By keeping the wiring in place, it ensures that all electrical connections remain secure, thereby maintaining the efficiency and reliability of the truck’s electrical system 2.

Key Features

The design of the Cummins 3964775 includes specific mounting points that allow it to be securely attached to the truck’s frame. It is constructed from durable materials that can withstand the rigors of commercial truck operation. The bracket is designed to be compatible with various truck models, ensuring that it can be used in a wide range of applications 3.

Benefits

The use of the Wiring Retainer Bracket offers several advantages. It improves wire management by keeping the wiring organized and secure, which reduces the risk of electrical faults. This, in turn, enhances the safety and reliability of the truck’s electrical system. Additionally, by maintaining the integrity of the wiring, it helps ensure that the electrical system operates efficiently, contributing to the overall performance of the truck 4.

Installation and Maintenance

Proper installation of the Wiring Retainer Bracket is important to ensure its effectiveness. It is recommended to use the appropriate tools and follow the manufacturer’s guidelines for installation. Regular maintenance, such as checking for secure connections and inspecting for damage, can help ensure that the bracket remains in optimal condition and continues to provide the intended benefits 5.

Troubleshooting Common Issues

Common issues associated with Wiring Retainer Brackets may include loose connections or damage to the bracket itself. If loose connections are detected, they should be secured to prevent potential electrical faults. If the bracket is damaged, it may need to be replaced to maintain the integrity of the wiring system. Regular inspections can help identify these issues early, allowing for timely intervention 6.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. The company has a long history of innovation and commitment to providing solutions that meet the needs of its customers. The Cummins 3964775 Wiring Retainer Bracket is just one example of the company’s dedication to providing high-quality components that contribute to the efficiency and reliability of commercial trucks 7.

Role of Part 3964775 Wiring Retainer Bracket in Engine Systems

The 3964775 Wiring Retainer Bracket is a component in organizing and securing the wiring within engine systems. It ensures that the wiring is neatly arranged, reducing the risk of tangling, abrasion, and potential damage during engine operation 8.

Integration with Accessories

When integrating with engine accessories, the 3964775 Wiring Retainer Bracket plays a role in maintaining the structural integrity of the wiring. Accessories such as alternators, fuel injectors, and sensors rely on consistent and reliable electrical connections. The bracket helps in routing the wires away from moving parts and high-temperature areas, thus protecting the integrity of the connections and ensuring that accessories function without interruption 9.

Securing Wiring

In engine systems, the wiring often needs to navigate through tight spaces and around various components. The 3964775 Wiring Retainer Bracket secures the wiring in place, preventing it from coming into contact with sharp edges or hot surfaces. This is particularly important in high-vibration environments where unsecured wiring can lead to chafing and eventual failure of electrical connections 10.

Enhancing System Reliability

By keeping the wiring organized and protected, the 3964775 Wiring Retainer Bracket contributes to the overall reliability of the engine system. It ensures that electrical signals are transmitted efficiently, reducing the likelihood of intermittent issues that can arise from poorly managed wiring. This enhances the performance and longevity of the engine components that depend on stable electrical supply 11.

Facilitating Maintenance

The use of the 3964775 Wiring Retainer Bracket also simplifies maintenance procedures. With wiring securely held in place, technicians can more easily access and diagnose issues within the engine system. It reduces the time required to trace wires and locate potential problems, leading to more efficient servicing and repairs 12.

Conclusion

The Cummins 3964775 Wiring Retainer Bracket is a vital component in the electrical systems of commercial trucks and engines. Its role in securing and organizing wiring harnesses contributes to the efficiency, reliability, and safety of the vehicle’s electrical system. Proper installation, regular maintenance, and timely troubleshooting of common issues are essential to ensure the continued effectiveness of this part.

-

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Cummins Inc. X15 CM2350 X123B, Service Manual (5504510).

↩ -

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Cummins Inc. X15 CM2350 X123B, Service Manual (5504510).

↩ -

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Cummins Inc. X15 CM2350 X123B, Service Manual (5504510).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.