This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

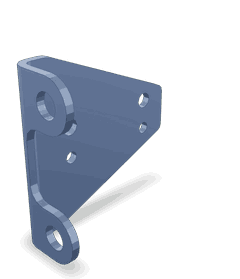

The Wiring Retainer Bracket (Part #3943975) manufactured by Cummins is a component designed to play a role in the electrical system of commercial trucks. It is engineered to secure and organize wiring harnesses, contributing to the overall efficiency and reliability of the truck’s electrical performance.

Purpose and Function

The Wiring Retainer Bracket serves to secure and organize wiring harnesses within the truck’s electrical system. By holding the wiring in place, it helps prevent damage from vibrations and movement, which can otherwise lead to wear and tear on the wires. This bracket ensures that the wiring remains neatly arranged, which is vital for maintaining efficient electrical performance and reducing the likelihood of electrical faults 1.

Key Features

The Wiring Retainer Bracket is characterized by its durable construction, which is designed to withstand the harsh conditions often encountered in commercial trucking environments. It is made from high-quality materials that offer resistance to corrosion and physical stress. The installation process is straightforward, requiring minimal tools and time. Additionally, the bracket is compatible with a variety of truck models, making it a versatile component for fleet management. Unique design elements, such as adjustable mounting points, enhance its functionality by allowing for precise placement and secure attachment of the wiring harnesses.

Benefits

Using the Wiring Retainer Bracket offers several advantages. It improves wire management by keeping the wiring organized and protected, which can lead to a reduction in the risk of electrical faults. This, in turn, enhances the safety and reliability of the truck’s electrical system. Proper wire management also contributes to overall truck performance by ensuring that electrical components receive consistent and uninterrupted power. Furthermore, the bracket’s durable construction and easy maintenance contribute to its long-term effectiveness and cost-efficiency 2.

Installation and Maintenance

For proper installation of the Wiring Retainer Bracket, it is recommended to use basic hand tools such as wrenches and screwdrivers. The installation process involves securing the bracket to the truck’s chassis and then attaching the wiring harnesses to the bracket. It is important to follow the manufacturer’s guidelines to ensure a secure attachment. Regular maintenance checks should be conducted to ensure that the bracket remains in optimal condition. This includes inspecting for any signs of wear or damage and ensuring that the wiring harnesses are properly secured.

Troubleshooting Common Issues

Common issues that may arise with the Wiring Retainer Bracket include loose connections or damage to the bracket itself. To troubleshoot these issues, begin by inspecting the bracket and wiring harnesses for any visible signs of damage or wear. If a loose connection is detected, re-secure the wiring to the bracket. In cases where the bracket is damaged, it may need to be replaced to ensure the electrical system remains functional and safe. Regular inspections and maintenance can help identify and resolve these issues before they lead to more significant problems.

Cummins: A Brief Overview

Cummins Inc. is a well-established company with a history of innovation in the automotive industry. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, all designed to meet the demanding needs of commercial trucking. Cummins is known for its commitment to quality and reliability, which is evident in its manufacturing processes and the performance of its products. The Wiring Retainer Bracket is just one example of Cummins’ dedication to providing high-quality components that contribute to the efficiency and safety of commercial vehicles.

Cummins Wiring Retainer Bracket 3943975 Compatibility

The Cummins Wiring Retainer Bracket part number 3943975 is designed to be compatible with several Cummins engine models. This bracket is essential for securing wiring harnesses and ensuring that electrical connections remain stable and protected within the engine compartment.

ISB CM550 Engines

The ISB CM550 engine series is one of the prominent applications for the Wiring Retainer Bracket 3943975. This engine is known for its robust performance and reliability, often used in heavy-duty applications such as commercial trucks and industrial equipment. The bracket’s design ensures that wiring is properly managed, reducing the risk of damage from vibrations and environmental factors.

Other Cummins Engines

While the ISB CM550 is a notable application, the Wiring Retainer Bracket 3943975 is also compatible with various other Cummins engine models. This versatility makes it a valuable component for technicians and fleet managers who need to maintain a wide range of engine types. The bracket’s universal design allows it to fit seamlessly across different engine configurations, providing a consistent solution for wiring management.

By ensuring that wiring is securely fastened, the bracket helps maintain the integrity of the engine’s electrical system, contributing to overall performance and longevity.

Role of Part 3943975 Wiring Retainer Bracket in Engine Systems

The 3943975 Wiring Retainer Bracket is a component in organizing and securing the wiring harnesses within engine systems. Its primary function is to maintain the integrity and order of the wiring, ensuring that cables are neatly routed and protected from potential damage caused by engine vibrations or heat.

Integration with Accessories

When integrating with accessories, the 3943975 Wiring Retainer Bracket plays a significant role in maintaining a tidy and efficient wiring layout. Accessories such as sensors, fuel injectors, and ignition components rely on consistent and secure wiring connections. The bracket helps in:

- Routing Wires: It guides wires away from moving parts and high-temperature areas, reducing the risk of abrasion or melting.

- Reducing Strain: By securing wires in place, it prevents undue stress on connectors and solder joints, which can lead to intermittent connections or failures.

- Facilitating Maintenance: A well-organized wiring system allows for easier diagnosis and repair of electrical issues, as wires are less likely to become tangled or obscured.

Securing Wiring Harnesses

In the context of wiring harnesses, the 3943975 Wiring Retainer Bracket ensures that bundles of wires are held firmly in place. This is particularly important in engine compartments where space is limited, and the environment is harsh. The bracket contributes to:

- Thermal Management: Keeping wires away from direct heat sources helps in maintaining optimal operating temperatures for electrical components.

- Vibration Dampening: By securing wires, the bracket mitigates the effects of engine vibrations, which can otherwise lead to wire fatigue and eventual failure.

- Space Optimization: It allows for more efficient use of the available space within the engine bay, ensuring that wires do not interfere with other components or obstruct airflow.

Conclusion

In summary, the 3943975 Wiring Retainer Bracket is a component in the engine system, enhancing the reliability and longevity of both accessories and wiring harnesses through organized and secure wiring management. Its durable construction, ease of installation, and compatibility with various engine models make it a valuable asset for maintaining the electrical integrity of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.