This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

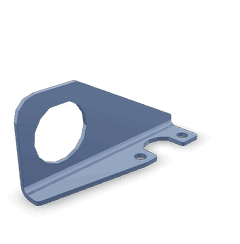

The Wiring Retainer Bracket part number 3943735, manufactured by Cummins, is a component designed to support the electrical system of commercial trucks. This Cummins part plays a role in organizing and securing wiring harnesses, contributing to the efficient operation and safety of the vehicle. Cummins, a well-established manufacturer in the diesel engine and component industry, produces this bracket to meet the demanding requirements of commercial trucking 1.

Basic Concepts of Wiring Retainer Brackets

A Wiring Retainer Bracket is a structural component used in a truck’s electrical system to hold and organize wiring harnesses. It ensures that wires are neatly arranged and securely fastened, which helps prevent chafing, abrasion, and potential electrical issues. Proper wire management is vital for the overall operation and safety of the vehicle, as it ensures that electrical connections remain intact and function as intended 2.

Purpose of the 3943735 Wiring Retainer Bracket

The 3943735 is specifically designed to play a role in the truck’s electrical system by organizing and securing wiring harnesses. It helps maintain the integrity of the electrical connections by keeping wires in place and protecting them from movement and potential damage. This bracket contributes to the reliability and safety of the truck’s electrical system by ensuring that wires are managed effectively 3.

Key Features

The 3943735 features a durable material composition, typically made from high-strength polymers or metals, ensuring it can withstand the rigors of commercial truck environments. Its design includes mounting points and clips that allow for secure attachment to the truck’s frame and wiring harnesses. Additionally, the bracket may incorporate features such as grommets or seals to protect wires from environmental factors, enhancing its functionality and longevity 4.

Benefits of Using the 3943735 Wiring Retainer Bracket

Using the 3943735 offers several advantages. It improves wire management by keeping harnesses organized and secured, which can reduce the risk of electrical issues such as short circuits or disconnected wires. The bracket’s durable construction enhances the overall durability of the electrical system, and its design can help reduce the likelihood of wire damage due to movement or external factors.

Installation Process

Installing the 3943735 involves several steps. First, identify the appropriate location on the truck’s frame where the bracket will be mounted. Using the provided mounting hardware, secure the bracket in place. Next, route the wiring harnesses through the bracket, ensuring they are properly aligned with the clips and mounting points. Finally, double-check all connections to ensure they are secure and that the wires are protected from potential damage.

Troubleshooting Common Issues

Common issues with Wiring Retainer Brackets may include loose connections or damaged brackets. To troubleshoot these problems, first, inspect the bracket and wiring harnesses for any signs of wear or damage. Ensure that all mounting points and clips are secure and that the wires are properly routed through the bracket. If loose connections are detected, re-secure the wires and bracket as necessary. For damaged brackets, replacement may be required to maintain the integrity of the electrical system.

Maintenance Tips

Regular maintenance of the 3943735 is important to ensure its longevity and optimal performance. Inspect the bracket and wiring harnesses during routine maintenance checks for any signs of wear, damage, or loose connections. Clean the bracket as needed to remove dirt and debris that could affect its functionality. Ensuring that the bracket remains in good condition will help maintain the reliability of the truck’s electrical system.

Cummins Overview

Cummins Inc. is a leading manufacturer with a rich history in the diesel engine and component industry. The company is renowned for its expertise in producing high-quality diesel engines and related components, including electrical system parts like the 3943735. Cummins’ reputation in the commercial truck industry is built on its commitment to innovation, quality, and customer satisfaction, making it a trusted name among fleet operators and maintenance professionals.

Role of Part 3943735 Wiring Retainer Bracket in Engine Systems

The 3943735 is an essential component in the integration and maintenance of wiring systems within engine assemblies. Its primary function is to secure and organize wiring harnesses, ensuring they remain in place and protected from potential damage during engine operation.

Integration with Accessories

When integrating with accessories, the Wiring Retainer Bracket plays a significant role in maintaining the structural integrity of the wiring system. It ensures that wires connected to accessories such as alternators, fuel injectors, and sensors are neatly organized and securely fastened. This organization prevents wires from becoming tangled or damaged, which could lead to electrical faults or system failures. The bracket also aids in reducing vibrations that could otherwise affect the performance of these accessories.

Wiring System Support

In the context of the overall wiring system, the Wiring Retainer Bracket is instrumental in supporting the complex network of wires that power various engine components. It helps in routing wires away from high-temperature areas and moving parts, thus minimizing the risk of wear and tear. Additionally, the bracket facilitates easier access for maintenance and repairs by keeping the wiring system tidy and well-organized. This is particularly beneficial during diagnostic procedures, where clear access to wiring is necessary to identify and resolve issues efficiently.

Conclusion

The effective use of the 3943735 enhances the reliability and durability of the engine’s electrical system, contributing to the overall performance and longevity of the engine.

-

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.