This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

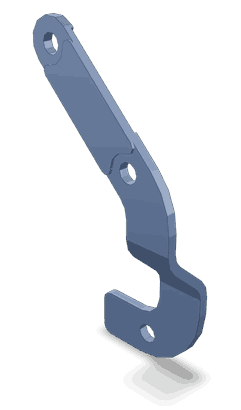

The Cummins Wiring Retainer Bracket, part number 3929866, is a component designed to secure and organize the wiring within heavy-duty trucks. Its role is significant in maintaining the integrity and efficiency of the truck’s electrical system. Cummins, a well-established name in the automotive industry, is known for producing reliable and high-quality parts that contribute to the optimal performance of heavy-duty vehicles 1.

Purpose and Function

The Wiring Retainer Bracket plays a role in the electrical system of a truck by securing and organizing the wiring. This bracket helps prevent damage to the wires from vibrations and other mechanical stresses that occur during operation. By keeping the wiring in place, it ensures that the electrical connections remain intact, which is vital for the efficient operation of the truck’s various electrical components 2.

Key Features

The Wiring Retainer Bracket is designed with durability in mind, utilizing materials that can withstand the harsh conditions often encountered in heavy-duty truck operations. Its design allows for ease of installation, making it a practical choice for both professional mechanics and DIY enthusiasts. The bracket is compatible with a range of truck models, ensuring versatility across different applications 3.

Benefits

Using the Wiring Retainer Bracket offers several advantages. It contributes to improved safety by reducing the risk of electrical faults that could arise from unsecured or damaged wiring. Additionally, it enhances the longevity of the wiring system by protecting the wires from wear and tear. This, in turn, can lead to fewer electrical issues and lower maintenance costs over time.

Installation Process

Installing the Wiring Retainer Bracket involves a few straightforward steps. First, identify the location where the bracket will be mounted within the truck’s electrical system. Next, align the bracket with the designated mounting points and secure it in place using the provided fasteners. Ensure that the wiring is properly routed through the bracket and that all connections are secure and aligned correctly.

Maintenance and Troubleshooting

Regular inspection of the Wiring Retainer Bracket is recommended to ensure it remains in good condition. Look for signs of wear, corrosion, or damage to the bracket and the wiring it secures. Common issues may include loose connections or damaged wires, which can often be addressed by re-securing the wiring or replacing damaged sections.

Compatibility and Usage

The Wiring Retainer Bracket is designed for use in specific types of trucks and electrical systems. It is important to verify compatibility with your truck model to ensure proper fit and function. Any specific usage notes or precautions provided by the manufacturer should be followed to maintain the effectiveness of the bracket.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the automotive industry, particularly in the heavy-duty truck sector, Cummins is committed to delivering reliable and innovative products that meet the demanding needs of its customers.

Wiring Retainer Bracket 3929866 by Cummins

The Wiring Retainer Bracket, part number 3929866, manufactured by Cummins, is a component designed to secure and organize the wiring harness in various engine configurations. This bracket ensures that the wiring remains neatly arranged, reducing the risk of damage and improving overall engine efficiency.

Compatibility with Cummins Engines

The Wiring Retainer Bracket is compatible with several Cummins engine models, including but not limited to:

-

6B5.9 Series: This bracket is specifically engineered to fit within the engine bay of the 6B5.9 series, providing a stable mounting point for the wiring harness. Its design allows for easy installation and adjustment, ensuring that the wiring is held securely in place during engine operation.

-

Other Cummins Engines: While the primary focus is on the 6B5.9 series, this bracket is also designed to be adaptable for use in other Cummins engine models. Its universal design ensures compatibility across a range of engine types, making it a versatile choice for engine maintenance and repair.

Installation and Functionality

When installing the Wiring Retainer Bracket, it is crucial to follow the manufacturer’s guidelines to ensure proper placement and secure attachment. The bracket is typically mounted using bolts or screws, which are provided with the part. Once installed, it serves to:

- Prevent Wire Damage: By securing the wiring harness, the bracket helps prevent wear and tear on the wires, which can lead to electrical issues and potential engine failures.

- Enhance Organization: Keeping the wiring organized reduces clutter in the engine bay, making it easier for technicians to perform maintenance and repairs.

- Improve Airflow: A well-organized wiring harness can also contribute to better airflow within the engine bay, which is essential for maintaining optimal engine performance.

Importance in Engine Maintenance

The Wiring Retainer Bracket plays a vital role in the overall maintenance and longevity of Cummins engines. By ensuring that the wiring harness is properly secured and organized, this component helps maintain the integrity of the engine’s electrical system. This is particularly important in high-stress environments where engines are subjected to frequent vibrations and temperature fluctuations.

Role of Part 3929866 Wiring Retainer Bracket in Engine Systems

The 3929866 Wiring Retainer Bracket is a component that ensures the secure and organized routing of wiring within engine systems. This bracket is particularly important when integrating with various engine components such as the control unit, gear shift mechanism, throttle position sensor (TPS), and the throttle control bracket.

Integration with Control Unit

In engine systems, the control unit manages various functions including fuel injection, ignition timing, and other critical operations. The 3929866 Wiring Retainer Bracket plays a significant role by keeping the wiring that connects to the control unit neat and protected. This prevents potential damage from vibrations or heat, ensuring reliable signal transmission.

Gear Shift Mechanism

The gear shift mechanism relies on precise electrical connections to communicate shift positions and commands. The 3929866 Wiring Retainer Bracket secures the wiring associated with the gear shift, reducing the risk of disconnections or shorts that could lead to erroneous gear changes or complete system failure.

Throttle Position Sensor (TPS)

Accurate readings from the TPS are vital for engine performance, as they inform the control unit about the position of the throttle valve. The 3929866 Wiring Retainer Bracket ensures that the wiring to the TPS remains intact and free from interference, maintaining the accuracy and reliability of throttle position data.

Throttle Control Bracket

The throttle control bracket is responsible for the physical linkage between the driver’s input and the throttle valve. The wiring that controls this bracket must be securely managed to avoid any disruptions. The 3929866 Wiring Retainer Bracket facilitates this by providing a stable and organized path for the wiring, enhancing the overall efficiency and safety of the throttle control system.

By effectively managing the wiring for these components, the 3929866 Wiring Retainer Bracket contributes to the smooth operation and longevity of the engine system.

Conclusion

The Cummins Wiring Retainer Bracket, part number 3929866, is an essential component for maintaining the electrical integrity and organization within heavy-duty trucks and Cummins engines. Its design and functionality make it a valuable asset for both routine maintenance and repair tasks, ensuring the reliable operation of the vehicle’s electrical system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.