This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

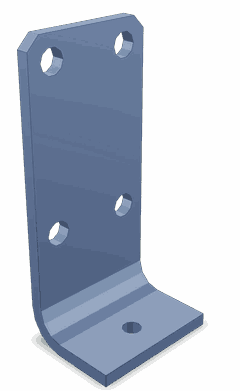

The Cummins 3925404 Shipping Bracket is a component designed to facilitate the secure transportation of truck parts. Its role is significant in commercial truck operations, where the safe and undamaged delivery of parts is crucial for maintaining operational efficiency and minimizing downtime.

Purpose and Function

The Cummins 3925404 Shipping Bracket secures and protects truck components during transportation. By providing a stable mounting point, it ensures that parts remain fixed and are less likely to shift or become damaged in transit. This function is vital for preserving the integrity of the components for proper installation and performance upon arrival 1.

Key Features

The primary features of the Cummins 3925404 Shipping Bracket include its robust material composition, typically a durable metal alloy, which offers resistance to corrosion and physical stress. The design elements of the bracket are tailored to accommodate various component sizes and shapes, ensuring a snug fit. Additionally, it may include features such as pre-drilled holes for easy attachment and a low-profile design to minimize space requirements during shipping 2.

Benefits

The Cummins 3925404 Shipping Bracket provides several advantages. It enhances safety during transit by securing components, reducing the risk of damage. Its durable construction contributes to longevity, allowing for repeated use. Furthermore, the bracket is designed for ease of installation, which can save time and labor costs during the packing process 3.

Installation Process

To install the Cummins 3925404 Shipping Bracket, begin by identifying the appropriate location on the truck component where the bracket will be attached. Use the provided hardware to secure the bracket in place, ensuring that it is firmly fastened. It is recommended to use a torque wrench to achieve the correct tightening specification, which can be found in the installation instructions. Once installed, verify that the bracket is stable and the component is securely mounted 4.

Maintenance and Care

To maintain the Cummins 3925404 Shipping Bracket, regular inspections should be conducted to check for any signs of wear or damage. Cleaning the bracket with a mild detergent and water solution will help prevent the buildup of dirt and grime, which can affect its performance. If any corrosion is detected, it should be addressed promptly to prevent further degradation.

Troubleshooting Common Issues

Common issues with the Cummins 3925404 Shipping Bracket may include loose connections or damage to the bracket itself. To address these problems, first, ensure that all fasteners are tightened to the specified torque. If the bracket is damaged, it may need to be replaced to maintain the security of the transported components.

Manufacturer Overview - Cummins

Cummins is a well-established manufacturer with a strong reputation in the industry for producing high-quality automotive and heavy-duty truck parts. The company has a history of innovation and commitment to excellence, which is reflected in the design and performance of their products, including the Cummins 3925404 Shipping Bracket.

Cummins Shipping Bracket 3925404 Compatibility

The Cummins Shipping Bracket part number 3925404 is designed to be compatible with a range of Cummins engines, ensuring secure and stable transportation during shipping and installation processes. This bracket is engineered to fit seamlessly with specific engine models, providing a robust solution for handling and mounting.

Engine Compatibility

- 6C8.3 Series: The 3925404 Shipping Bracket is specifically engineered for the 6C8.3 engine series. This bracket ensures that the engine remains securely fastened during transit, minimizing the risk of damage and ensuring that the engine arrives at its destination in optimal condition.

Understanding the Integration of Part 3925404 Shipping Bracket in Engine Systems

When integrating the part 3925404 shipping bracket into engine systems, it is essential to understand its role in securing and organizing various components during transit. This bracket is designed to ensure that engine parts remain stable and protected, minimizing the risk of damage during shipping.

Role in Engine Component Security

The shipping bracket, part 3925404, is primarily used to secure engine components such as the cylinder head, intake manifold, and exhaust manifold. By firmly holding these parts in place, the bracket prevents them from shifting or colliding with other components during transportation. This stability is vital for maintaining the integrity of sensitive engine parts, ensuring they arrive in optimal condition for installation.

Interaction with Ancillary Components

In addition to securing primary engine components, the shipping bracket also interacts with ancillary parts like sensors, wiring harnesses, and smaller mechanical components. These items are often more susceptible to damage from movement. The bracket provides a structured environment where these parts can be nestled safely, reducing the likelihood of entanglement or breakage.

Facilitation of Organized Packing

The use of part 3925404 in engine systems extends beyond mere security. It aids in the organized packing of engine components, allowing for easier access and identification upon arrival. This organization is particularly beneficial in high-volume shipping scenarios where multiple engine parts need to be efficiently sorted and retrieved.

Enhanced Protection for Fragile Parts

For components like the turbocharger or fuel injectors, which are both complex and fragile, the shipping bracket offers an added layer of protection. By immobilizing these parts, the bracket helps prevent the types of impacts and vibrations that could lead to malfunctions or require additional repairs post-shipment.

Support for Comprehensive Engine Kits

In scenarios where entire engine kits are being shipped, the bracket plays a supportive role in maintaining the structural integrity of the kit. It ensures that all components, from the crankshaft to the valve covers, are held in a configuration that mirrors their installation positions. This similarity simplifies the reassembly process and reduces the potential for errors during installation.

Conclusion

The integration of part 3925404 shipping bracket into engine systems is a thoughtful approach to enhancing the safety and efficiency of engine component transportation. Its role in securing, organizing, and protecting engine parts underscores its importance in the shipping process.

-

Sclar, Deanna. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩ -

Taghavifar, Hamid and Mardani, Aref. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Williams, Daniel. Generalized Vehicle Dynamics. SAE International, 2022.

↩ -

Bonneau, Dominique, Fatu, Aurelian, and Souchet, Dominique. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.