This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

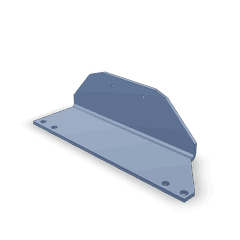

The Cummins 3924952 Instrument Bracket is a component designed for use in heavy-duty truck instrumentation systems. Its purpose is to support and secure various instruments within the truck’s dashboard, ensuring they remain in place and function correctly under the demanding conditions typical of heavy-duty operations. This part is significant for maintaining the integrity and reliability of the truck’s instrumentation, which is vital for safe and efficient operation.

Basic Concepts of Instrument Brackets

An instrument bracket serves as a mounting structure for vehicle instrumentation. It plays a role in securing gauges, displays, and other monitoring devices within the vehicle’s dashboard. By providing a stable platform, the bracket ensures that these instruments remain fixed and operational, even under the vibrations and stresses encountered during heavy-duty truck operations. The bracket integrates with other components by connecting to the dashboard framework and supporting the instruments, allowing for easy access and visibility to the driver 1.

Purpose of the Cummins 3924952 Instrument Bracket

The Cummins 3924952 Instrument Bracket is specifically designed to support and secure instruments in heavy-duty trucks. It plays a role in the operation of a truck by providing a stable mounting solution for gauges and displays, ensuring they remain in place and function correctly. This part is engineered to withstand the rigors of heavy-duty use, offering a reliable platform for critical instrumentation.

Key Features

The Cummins 3924952 Instrument Bracket features a robust construction, typically made from high-strength materials to ensure durability under heavy-duty conditions. Its design includes precise mounting points and secure attachment mechanisms to hold instruments firmly in place. Additionally, the bracket may incorporate features such as vibration damping elements to enhance stability and reduce the impact of road vibrations on the instruments 2.

Benefits

The Cummins 3924952 Instrument Bracket offers several benefits, including improved instrument stability, which ensures that gauges and displays remain securely in place during operation. Its design facilitates ease of installation, allowing for quick and straightforward mounting of instruments. Furthermore, the bracket’s durable construction contributes to its longevity, providing reliable support for instrumentation over the truck’s lifespan.

Installation Process

Installing the Cummins 3924952 Instrument Bracket involves several steps to ensure a secure fit. Begin by identifying the correct mounting location on the dashboard. Use the provided hardware to attach the bracket to the dashboard, ensuring all screws and fasteners are tightened securely. Once the bracket is in place, mount the instruments according to the manufacturer’s instructions, making sure they are properly aligned and secured. Tools required may include a screwdriver and possibly a drill for pilot holes, depending on the dashboard material.

Common Issues and Troubleshooting

Common issues with the Cummins 3924952 Instrument Bracket may include loose mounting, which can cause instruments to become unstable. To address this, ensure all fasteners are tightened securely and check for any signs of wear or damage to the bracket or mounting points. If instruments are not aligning correctly, verify that the bracket is installed level and that there are no obstructions preventing proper mounting. Regular inspection and maintenance can help identify and resolve these issues promptly.

Maintenance Tips

To maintain the Cummins 3924952 Instrument Bracket and ensure its longevity, regular inspection is recommended. Check for any signs of wear, corrosion, or damage to the bracket and its mounting points. Clean the bracket periodically to remove dirt and debris that may accumulate, using a mild cleaner and a soft cloth. Ensure that all fasteners remain tight and that instruments are securely mounted. Following these maintenance practices will help preserve the bracket’s performance and reliability.

Compatibility and Applications

The Cummins 3924952 Instrument Bracket is designed for use with specific types of trucks and engine models. It is compatible with a range of Cummins engines commonly found in heavy-duty truck applications. This compatibility ensures that the bracket can be effectively utilized across various fleet operations, providing a reliable mounting solution for instrumentation in these vehicles.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of engines, components, and systems designed to meet the demanding requirements of heavy-duty applications 3.

Role of the 3924952 Instrument Bracket in Engine Systems

The 3924952 Instrument Bracket is an essential component in the assembly and operation of various engine systems. It provides a secure mounting point for instruments and gauges, ensuring they are properly positioned and protected within the engine environment.

Integration with the Package

When integrating the Instrument Bracket with the engine package, it serves as a foundational element. The bracket is affixed to the package, which typically houses the engine’s primary components. This secure attachment ensures that instruments are held firmly in place, minimizing the risk of displacement or damage during engine operation. The bracket’s design allows for easy access to the instruments, facilitating regular monitoring and maintenance of engine performance metrics.

Coordination with the Guard

The Instrument Bracket also plays a significant role when coordinated with the engine guard. The guard is designed to protect the engine and its components from external debris and impacts. By mounting instruments on the bracket, which is then secured to the guard, the bracket ensures that these sensitive gauges are shielded while still being readily accessible. This setup maintains the integrity of the engine’s monitoring systems, allowing for accurate and consistent data collection without compromising safety.

Conclusion

The Cummins 3924952 Instrument Bracket is a vital component in the instrumentation systems of heavy-duty trucks. Its robust construction, precise mounting points, and vibration damping features ensure that instruments remain stable and operational under demanding conditions. Proper installation, regular maintenance, and understanding its role within the engine system contribute to the reliable performance of this Cummins part, enhancing the overall efficiency and safety of heavy-duty truck operations.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.