This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

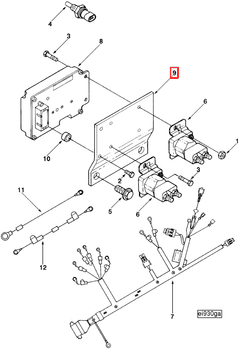

The Control Bracket Assembly, part number 3918347, manufactured by Cummins, is a component designed for use in heavy-duty truck operations. Cummins, a well-established name in the automotive industry, particularly in the heavy-duty truck sector, produces this part to meet the demanding requirements of commercial and industrial applications. The Control Bracket Assembly plays a role in supporting and securing various components within the truck’s engine system, contributing to the overall efficiency and reliability of the vehicle.

Purpose and Function

The Control Bracket Assembly serves to mount and support critical components within the engine compartment of heavy-duty trucks. It interacts with other systems by providing a stable platform for the attachment of sensors, actuators, and other control devices. This assembly ensures that these components remain securely in place, even under the harsh conditions typically encountered in heavy-duty operations. Its design allows for efficient heat dissipation and protects sensitive electronic components from physical damage and environmental factors 1.

Key Features

The Control Bracket Assembly is constructed from high-strength materials, ensuring durability and resistance to corrosion. Its design incorporates precise mounting points and alignment features to facilitate easy installation and accurate component placement. The assembly is engineered to withstand significant mechanical stress and thermal expansion, maintaining its integrity over the vehicle’s operational life. Additionally, it features integrated cable management solutions to organize wiring and reduce the risk of damage or interference 2.

Benefits

Incorporating the Control Bracket Assembly into heavy-duty truck designs offers several advantages. It contributes to improved stability of engine components, which can lead to enhanced overall performance and reliability. The assembly’s robust construction and design help minimize maintenance requirements and reduce the likelihood of component failure. For fleet operators, this can translate into potential cost savings through decreased downtime and lower repair expenses 3.

Installation Process

Proper installation of the Control Bracket Assembly involves several steps to ensure optimal functionality. Begin by preparing the engine compartment, ensuring that the mounting surface is clean and free of obstructions. Align the assembly with the designated mounting points, using the provided hardware to secure it in place. Carefully connect any sensors or actuators to the bracket, following the manufacturer’s guidelines for wiring and component placement. Finally, perform a thorough inspection to confirm that all connections are secure and that the assembly is properly aligned.

Maintenance and Troubleshooting

Regular maintenance of the Control Bracket Assembly is important to ensure continued performance and reliability. Inspect the assembly periodically for signs of wear, corrosion, or damage. Clean the bracket and connected components to remove any debris or buildup that could affect operation. If issues arise, such as loose connections or component malfunctions, refer to the manufacturer’s troubleshooting guide for guidance on identifying and addressing common problems.

Safety Considerations

When working with the Control Bracket Assembly, it is important to observe several safety protocols to protect mechanics and operators. Ensure that the engine is turned off and has cooled sufficiently before beginning any work. Use appropriate personal protective equipment, such as gloves and safety glasses, to guard against injury. Follow all manufacturer guidelines and safety instructions to minimize the risk of accidents or component damage during installation, maintenance, or repair procedures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, innovation, and reliability in the automotive industry. The company’s product range includes diesel and natural gas engines, as well as related technologies and services, catering to a variety of applications, including heavy-duty trucks, agriculture, construction, and power generation. Cummins’ commitment to excellence and customer satisfaction has made it a preferred choice among fleet operators and equipment manufacturers worldwide.

Cummins Control Bracket Assembly 3918347

The Cummins Control Bracket Assembly, part number 3918347, is a component in the engine’s operational framework. This assembly is designed to securely mount and position various control mechanisms, ensuring precise and reliable engine performance.

Compatibility with Cummins Engines

The 3918347 Control Bracket Assembly is engineered to fit seamlessly with several Cummins engine models. Here are the engines where this part is applicable:

- 6B5.9: This engine model benefits from the robust design of the 3918347 Control Bracket Assembly, which ensures that control components are properly aligned and secured. This assembly plays a role in maintaining the integrity of the engine’s control systems, contributing to overall engine efficiency and longevity.

Installation and Functionality

The installation of the 3918347 Control Bracket Assembly is a straightforward process, designed to integrate smoothly with the engine’s existing framework. Once installed, the assembly provides a stable base for control components, ensuring that they remain in optimal positions throughout the engine’s operation. This stability is important for the precise functioning of the engine’s control systems, which directly impact performance and reliability.

Importance in Engine Performance

The 3918347 Control Bracket Assembly is integral to the engine’s performance, as it supports the mounting of various control mechanisms. By providing a secure and stable platform, this assembly helps maintain the alignment and functionality of these components, which is important for the engine’s overall performance. Proper installation and maintenance of this bracket assembly are key to ensuring that the engine operates at peak efficiency.

Role of Part 3918347 Control Bracket Assembly in Engine Systems

The Control Bracket Assembly is an integral component in the orchestration of various engine systems, ensuring seamless integration and operation.

In the context of the Air Intake Heater, the Control Bracket Assembly secures and aligns the heater unit, allowing it to efficiently warm the incoming air before it reaches the engine. This ensures optimal combustion efficiency and protects the engine from cold-start issues.

When considering Engine Instruments, the Control Bracket Assembly plays a supportive role by providing a stable mounting point. This stability is essential for accurate readings and reliable performance of instruments such as temperature gauges, pressure sensors, and other diagnostic tools.

For the Instrument Cluster, the Control Bracket Assembly ensures that all gauges and displays are properly aligned and secured. This not only enhances the aesthetic appeal of the dashboard but also ensures that all readings are clear and unobstructed for the operator.

In relation to the Engine itself, the Control Bracket Assembly facilitates the attachment of various control modules and sensors. This integration allows for precise monitoring and management of engine performance, contributing to overall efficiency and reliability.

Lastly, in multi-engine setups, the Control Bracket Assembly aids in the synchronization of Engines. By providing a common mounting point for control systems, it helps in maintaining balanced operation across all engines, which is particularly important in aviation and marine applications.

Overall, the Control Bracket Assembly is a foundational element that enhances the functionality and reliability of engine systems through precise alignment and secure mounting of critical components.

Conclusion

The Control Bracket Assembly, part number 3918347, manufactured by Cummins, is a vital component in heavy-duty truck engine systems. Its robust design, precise mounting features, and integrated cable management solutions contribute to the stability, efficiency, and reliability of engine operations. Proper installation, regular maintenance, and adherence to safety protocols are essential to maximize the benefits of this part, ensuring optimal performance and longevity of the engine systems it supports.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Caines, A. J., Haycock, R. F., & Hillier, J. E. (2004). Automotive Lubricants Reference Book. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.