This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

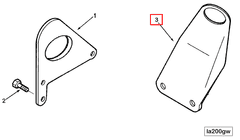

The Cummins 3892192 Lifting Bracket is a specialized component designed for use in commercial trucks. Its primary function is to facilitate the safe and efficient lifting of heavy components during maintenance and repair procedures. By providing a secure attachment point for lifting equipment, this part plays a role in ensuring that operations are conducted with minimal risk to personnel and equipment 1.

Basic Concepts of Lifting Brackets

Lifting brackets are integral to vehicle maintenance and repair, particularly in the context of heavy-duty trucks. These components serve as secure attachment points for lifting equipment, allowing for the safe manipulation of heavy parts. In the operation of lifting brackets, it is important to consider factors such as load distribution, material strength, and environmental conditions to ensure effective and safe use 2.

Purpose of the 3892192 Lifting Bracket

The Cummins 3892192 Lifting Bracket is specifically designed to enhance the safety and efficiency of lifting operations in commercial trucks. It is used to secure and stabilize components during lifting, reducing the risk of accidents and ensuring that the lifting process is conducted smoothly. This bracket is particularly useful in scenarios where heavy components need to be moved or positioned accurately.

Key Features

The Cummins 3892192 Lifting Bracket is characterized by several design elements and material properties that contribute to its effectiveness. Constructed from high-strength materials, it offers a robust load-bearing capacity. The bracket features strategically placed attachment points that allow for secure and stable connections to lifting equipment. Its design ensures that it can withstand the rigors of heavy-duty use while providing reliable performance.

Benefits

Utilizing the Cummins 3892192 Lifting Bracket offers several advantages. It enhances safety during lifting operations by providing a secure attachment point, reducing the risk of accidents. Additionally, it improves efficiency in maintenance tasks by allowing for quick and easy attachment of lifting equipment. Over time, the use of this bracket can lead to potential cost savings by minimizing the need for additional equipment and reducing the likelihood of damage to components during lifting.

Installation Process

Installing the Cummins 3892192 Lifting Bracket requires careful attention to detail and adherence to safety guidelines. The process involves identifying the appropriate location on the truck for attachment, ensuring that the surface is clean and free of debris. Using the recommended tools, the bracket is securely fastened in place. It is important to follow the manufacturer’s instructions and observe all safety precautions during installation to ensure proper functionality and longevity.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 3892192 Lifting Bracket include wear and tear, corrosion, and improper installation. Regular inspection and maintenance are recommended to identify these problems early and address them promptly. Cleaning the bracket regularly, checking for signs of damage, and ensuring that all attachment points are secure are important practices to maintain the bracket’s performance and longevity.

Safety Considerations

When using the Cummins 3892192 Lifting Bracket, it is important to observe several safety guidelines and best practices. These include understanding the weight limits of the bracket, ensuring that it is used in appropriate environmental conditions, and following proper usage scenarios as outlined by the manufacturer. Additionally, it is crucial to use the bracket in conjunction with compatible lifting equipment and to conduct regular safety checks to ensure ongoing reliability.

Cummins Overview

Cummins Inc. is a well-established company with a rich history in the commercial truck industry. Known for its innovative products and commitment to quality, Cummins offers a wide range of components and systems designed to enhance the performance and reliability of commercial vehicles. The company’s reputation is built on a foundation of expertise, customer satisfaction, and continuous improvement, making it a trusted name in the industry 3.

Cummins Lifting Bracket 3892192 Compatibility

The Cummins Lifting Bracket part number 3892192 is designed to be compatible with a range of engine models, ensuring versatility and ease of use across various applications. This lifting bracket is engineered to provide secure and reliable support during maintenance and repair operations.

L10 Series Engines

The Cummins Lifting Bracket 3892192 is specifically engineered to fit the L10 series engines, which include both the L10 GAS and L10 MECHANICAL variants. These engines are known for their robust performance and reliability, making them a popular choice in various industrial and commercial applications.

-

L10 GAS: This engine variant is designed for applications where gaseous fuels are utilized. The lifting bracket ensures that the engine can be safely lifted and maneuvered during maintenance, reducing the risk of damage and ensuring efficient service.

-

L10 MECHANICAL: For applications requiring mechanical power, the L10 MECHANICAL engine is a reliable choice. The lifting bracket is designed to provide the necessary support for this engine type, facilitating smooth and secure handling during maintenance procedures.

The compatibility of the Cummins Lifting Bracket 3892192 with the L10 series engines underscores its versatility and effectiveness in supporting a range of engine types within the same series. This ensures that maintenance personnel can use a single lifting solution for multiple engine models, streamlining the maintenance process and enhancing operational efficiency.

Role of Part 3892192 Lifting Bracket in Engine Systems

The part 3892192 Lifting Bracket is an integral component in the assembly and maintenance of engine systems. It is primarily used to facilitate the safe and efficient lifting of heavy engine components during installation, removal, or repair processes.

When integrating the Lifting Bracket with engine systems, it is often attached to the engine block or other substantial components to provide a secure point for lifting equipment such as cranes or hoists. This ensures that the weight is evenly distributed, minimizing the risk of damage to the engine or injury to personnel.

In addition to its primary function, the Lifting Bracket also plays a role in aligning engine components during assembly. By providing a stable and consistent lifting point, it helps ensure that components are positioned accurately, which is essential for the proper functioning of the engine.

The Lifting Bracket is also used in conjunction with other engine components such as the flywheel, crankshaft, and cylinder heads. For instance, when removing the cylinder head, the Lifting Bracket can be attached to the engine block to provide a stable base, allowing the cylinder head to be lifted off without exerting undue stress on the remaining components.

Furthermore, the Lifting Bracket is often employed during the replacement of the flywheel or crankshaft. By securing the Lifting Bracket to the engine block, mechanics can safely lift these heavy components into place, ensuring they are aligned correctly with the other engine parts.

In summary, the part 3892192 Lifting Bracket is a versatile and essential tool in the maintenance and repair of engine systems. Its role in providing a secure lifting point for heavy components cannot be overstated, making it a fundamental part of any engine maintenance toolkit.

Conclusion

The Cummins 3892192 Lifting Bracket is a critical component for the safe and efficient maintenance of commercial trucks and engine systems. Its robust design, compatibility with various engine models, and the benefits it offers in terms of safety and efficiency make it an indispensable tool for mechanics and maintenance professionals. Regular maintenance and adherence to safety guidelines ensure the longevity and reliability of this part, contributing to the overall performance and reliability of the vehicles it supports.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.