This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Breather Bracket 3688810, manufactured by Cummins, is a component integral to the maintenance and operation of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts designed to enhance the efficiency and reliability of truck engines. This part plays a significant role in the engine’s ventilation system.

Basic Concepts and Functionality

A breather bracket is a part of a truck’s engine system designed to facilitate the ventilation of the engine compartment. It allows for the exchange of air, which helps in maintaining optimal engine temperature and pressure. By enabling the release of excess pressure and the intake of fresh air, the breather bracket contributes to the overall health and efficiency of the engine 1.

Purpose of the 3688810 Breather Bracket

This Cummins part is specifically designed to support the ventilation system of a truck’s engine. It plays a role in managing the airflow within the engine compartment, which is vital for dissipating heat and maintaining pressure levels. This, in turn, supports the engine’s performance and longevity 2.

Key Features

The 3688810 is constructed with durable materials, ensuring it can withstand the harsh conditions of commercial truck operation. Its design includes features that enhance its functionality, such as precise fittings for secure attachment and optimal airflow. Additionally, the bracket may incorporate elements that facilitate easy installation and maintenance.

Benefits

The use of the 3688810 can lead to improved engine performance through better ventilation. It contributes to the engine’s longevity by helping to maintain optimal operating conditions. Furthermore, its design may simplify maintenance procedures, reducing downtime and enhancing the overall efficiency of truck operations.

Installation Process

Installing the 3688810 involves several steps to ensure it is properly secured and functions as intended. The process includes preparing the engine compartment, attaching the bracket to its designated location, and verifying that it is correctly installed. Specific considerations may include ensuring all connections are secure and that the bracket does not obstruct other components.

Troubleshooting Common Issues

Common issues with breather brackets may include blockages or damage that impede airflow. These problems can often be traced back to debris accumulation or physical damage. Solutions may involve cleaning the bracket or replacing it if damage is detected. Regular inspections can help identify and address these issues before they lead to more significant problems 3.

Maintenance Tips

Regular maintenance of the 3688810 is key to ensuring its optimal performance. This includes periodic inspections for signs of wear or damage, cleaning to remove any accumulated debris, and verifying that all connections remain secure. Adhering to a maintenance schedule can help prevent issues and extend the lifespan of the bracket.

Compatibility with Cummins Engines

This part is designed to fit seamlessly with a variety of Cummins engine models, ensuring proper ventilation and management of crankcase pressure, contributing to the overall efficiency and longevity of the engine.

ISX Series Engines

- ISX CM871

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

QSX Series Engines

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

X15 Series Engines

- X15 CM2350 X116B

- X15 CM2350 X123B

Understanding the Integration of Part 3688810 in Engine Systems

This part is an essential component in the arrangement of various engine systems, particularly when dealing with crankcase breather systems. Its role is to provide a secure mounting point for the breather, ensuring that the breather is correctly positioned and aligned within the engine’s crankcase.

Integration with Crankcase Breather System

In the crankcase breather system, the breather bracket facilitates the connection between the breather and the crankcase. This connection is vital for the efficient operation of the system, as it allows for the release of pressure build-up within the crankcase. The bracket ensures that the breather is held firmly in place, preventing any potential leaks or misalignments that could compromise the system’s performance.

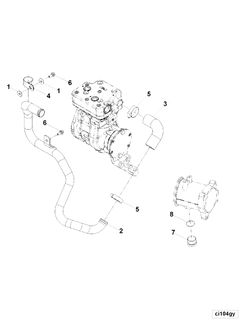

Role in Air Compressor Kit

When incorporated into an air compressor kit, the breather bracket plays a part in maintaining the structural integrity of the kit’s components. It ensures that the breather is securely attached, which is important for the safe and efficient operation of the compressor. This is particularly relevant in scenarios where the compressor is subjected to vibrations or varying operational conditions.

Importance in Plumbing and Arrangement

In the context of engine plumbing and overall arrangement, the breather bracket contributes to the organized and efficient layout of components. By providing a stable mounting solution for the breather, it allows for better management of space within the engine compartment. This is especially beneficial in compact engine designs where every inch of space is utilized effectively.

Enhancing System Reliability

The use of a breather bracket like part 3688810 is a testament to the attention to detail required in engine system design. It underscores the importance of secure and reliable component mounting in ensuring the longevity and performance of engine systems. Whether it’s part of a crankcase breather system, an air compressor kit, or the overall engine arrangement, the breather bracket plays a significant role in maintaining system reliability and efficiency.

Conclusion

Through this detailed examination of the Breather Bracket 3688810 by Cummins, it becomes clear how this component contributes to the efficient operation and maintenance of commercial trucks. Understanding its function, features, and the importance of proper installation and maintenance can help ensure the longevity and performance of truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.