This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

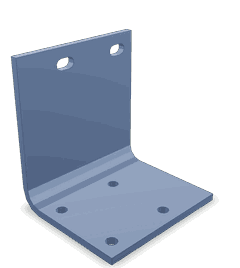

The Corrosion Resistor Bracket 3651937, manufactured by Cummins, is a component designed to enhance the durability and reliability of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems aimed at improving the performance and longevity of trucks. This part plays a role in protecting critical components from the adverse effects of corrosion, thereby contributing to the overall efficiency and maintenance of commercial trucks 1.

Basic Concepts of Corrosion Resistor Brackets

A Corrosion Resistor Bracket is a component used in the construction of commercial trucks to protect against corrosion. Its primary function is to shield various parts of the truck’s structure from the damaging effects of moisture, chemicals, and other corrosive elements. This is achieved through the bracket’s material composition and design, which are specifically chosen to resist corrosion. By doing so, the bracket helps maintain the integrity of the truck’s components, ensuring they operate efficiently over time 2.

Purpose of the 3651937 Corrosion Resistor Bracket

The 3651937 Corrosion Resistor Bracket is designed to play a specific role in the operation and maintenance of commercial trucks. It is strategically placed to interact with other components, providing a protective barrier against corrosion. This bracket is integral to the truck’s structure, ensuring that critical parts remain unaffected by environmental factors that could lead to corrosion. Its placement and interaction with other components are crucial for the bracket to effectively perform its protective function 3.

Key Features

The 3651937 Corrosion Resistor Bracket boasts several key features that enhance its performance and durability. It is composed of materials known for their resistance to corrosion, ensuring long-lasting protection. The design of the bracket includes elements that facilitate easy installation and integration with the truck’s structure. Additionally, any unique characteristics, such as specific coatings or treatments, further enhance its ability to resist corrosion and maintain the integrity of the truck’s components 1.

Benefits

Utilizing the 3651937 Corrosion Resistor Bracket offers several advantages. It contributes to the improved longevity of truck components by providing a protective barrier against corrosion. This, in turn, can lead to reduced maintenance costs, as components are less likely to fail or require replacement due to corrosion. Furthermore, the bracket enhances the overall performance of the truck by ensuring that its components operate efficiently and reliably over time 2.

Installation Process

Installing the 3651937 Corrosion Resistor Bracket requires following a step-by-step process to ensure it is securely fitted. The installation may require specific tools and additional components, depending on the truck’s make and model. Best practices for installation include carefully following the manufacturer’s guidelines, ensuring all connections are secure, and verifying that the bracket is correctly aligned with other components. This ensures the bracket effectively performs its protective function 3.

Troubleshooting and Maintenance

Common issues that may arise with the 3651937 Corrosion Resistor Bracket include signs of wear, damage, or reduced effectiveness in corrosion resistance. Identifying these problems early can prevent more significant issues down the line. Recommended maintenance practices include regular inspections for signs of corrosion or damage, cleaning the bracket to remove any buildup that could impede its function, and replacing the bracket if it shows significant wear or damage. These practices help prolong the bracket’s lifespan and maintain its effectiveness 1.

Environmental and Operational Considerations

Different environmental conditions and operational stresses can impact the performance of the 3651937 Corrosion Resistor Bracket. Exposure to harsh chemicals, extreme temperatures, or high humidity can affect the bracket’s ability to resist corrosion. To mitigate these effects, it is important to consider the operating environment when selecting and maintaining the bracket. Additionally, regular maintenance and inspections can help identify any issues early, allowing for timely interventions to ensure the bracket continues to protect the truck’s components effectively 2.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance parts and systems, Cummins has established a strong reputation in the industry. The company’s product range includes a variety of components designed to enhance the efficiency, reliability, and longevity of commercial trucks. Cummins’ dedication to quality is evident in its rigorous testing and development processes, ensuring that its products meet the high standards required in the commercial truck industry 3.

Compatibility with Engine Models

The 3651937 Corrosion Resistor Bracket is compatible with various Cummins engine models, including K50, QSK50, CM2150, and MCRS engines. In each engine series, this part is strategically placed to protect key areas susceptible to corrosion, ensuring the structural integrity of the engine is maintained over time.

K50 Engines

In the K50 engine series, the Corrosion Resistor Bracket is integral in securing components that are exposed to moisture and other corrosive elements, thereby preventing degradation and maintaining the engine’s operational efficiency.

QSK50 and CM2150 Engines

For the QSK50 and CM2150 engines, the bracket’s design ensures that it fits seamlessly into the engine’s architecture, providing a reliable barrier against corrosion without compromising the engine’s performance.

MCRS Engines

The MCRS engine series also incorporates the Corrosion Resistor Bracket. This part is essential in protecting the engine’s internal components from the corrosive effects of exhaust gases and other environmental factors. The bracket’s placement is critical, ensuring that it provides maximum protection to the areas most vulnerable to corrosion.

By integrating the Corrosion Resistor Bracket into these engines, Cummins ensures that the longevity and reliability of the engines are maintained, providing peace of mind to operators and enhancing the overall performance of the engine systems 1.

Role of Part 3651937 Corrosion Resistor Bracket in Engine Systems

The Part 3651937 Corrosion Resistor Bracket is integral to the assembly and functionality of various engine components. It is specifically designed to enhance the durability and performance of the engine system by providing a robust mounting solution for the head corrosion resistor.

Integration with Head Corrosion Resistor

The head corrosion resistor is a component that plays a significant role in protecting the engine head from corrosion. The Part 3651937 Corrosion Resistor Bracket securely mounts this resistor, ensuring it remains in the optimal position to perform its protective functions effectively. This bracket is engineered to withstand the harsh conditions within the engine compartment, thereby prolonging the lifespan of the head corrosion resistor.

Mounting and Stability

In addition to supporting the head corrosion resistor, the Part 3651937 Corrosion Resistor Bracket also provides a stable platform for other corrosion resistors. These resistors are essential for maintaining the integrity of various engine components by preventing corrosion. The bracket’s design ensures that these resistors are held firmly in place, reducing the risk of displacement or damage during engine operation.

Overall Engine Protection

By securely mounting corrosion resistors, the Part 3651937 Corrosion Resistor Bracket contributes to the overall protection of the engine. This is particularly important in environments where the engine is exposed to moisture, salt, or other corrosive elements. The bracket’s corrosion-resistant properties ensure that it remains effective over time, providing consistent support for the resistors and enhancing the engine’s reliability.

Enhanced Performance

The stable and secure mounting provided by the Part 3651937 Corrosion Resistor Bracket allows the corrosion resistors to function more effectively. This results in improved engine performance and reduced maintenance requirements. The bracket’s role in maintaining the proper positioning of these components is essential for the engine’s long-term health and efficiency 2.

Conclusion

The 3651937 Corrosion Resistor Bracket is a vital component in the maintenance and operation of commercial trucks and Cummins engines. Its role in protecting critical components from corrosion ensures the longevity and reliability of the truck and engine systems. By understanding its features, benefits, and proper installation and maintenance practices, operators can maximize the effectiveness of this Cummins part, leading to improved performance and reduced maintenance costs 3.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.