This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

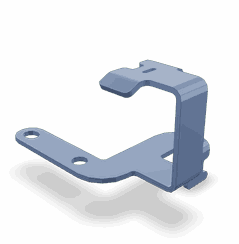

The Cummins Wiring Retainer Bracket, part number 3651844, is a component designed to play a role in the electrical system of commercial trucks. This bracket is integral to the organization and security of wiring harnesses within the vehicle, contributing to both the performance and safety of the truck. Cummins, a well-established name in the commercial truck industry, is known for its commitment to quality and innovation in truck components.

Basic Concepts of Wiring Retainer Brackets

A Wiring Retainer Bracket is a device used in a truck’s electrical system to hold and organize wiring harnesses. Its function is to secure the wires in place, preventing them from moving around or coming into contact with other parts of the vehicle, which could lead to electrical faults or damage. By maintaining the integrity of the wiring system, these brackets contribute to the overall performance and safety of the vehicle 1.

Purpose of the 3651844 Wiring Retainer Bracket

The 3651844 Wiring Retainer Bracket is specifically designed to organize and secure wiring harnesses within the truck’s electrical system. It plays a role in keeping the wires neatly arranged and protected from potential damage, which helps in maintaining the efficiency and reliability of the electrical connections throughout the vehicle.

Key Features

This Cummins part is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operations. Its design includes features that allow for easy installation and adjustment, accommodating various wiring configurations. Additionally, the bracket may have unique characteristics such as corrosion resistance or a design that allows for better airflow around the wiring, enhancing its functionality.

Benefits

Using the 3651844 Wiring Retainer Bracket offers several advantages. It improves wire management by keeping the wiring harnesses organized and secure, which can reduce the risk of electrical faults. The bracket’s durable construction enhances the longevity of the wiring system, contributing to the overall reliability of the truck’s electrical components.

Installation Process

Installing this part involves several steps to ensure it is properly secured and functions as intended. The process may require specific tools and could involve additional components depending on the truck’s wiring configuration. Following the manufacturer’s guidelines for installation is recommended to ensure the bracket is correctly positioned and fastened.

Troubleshooting and Maintenance

Common issues with Wiring Retainer Brackets may include loose connections or damage to the bracket itself. Troubleshooting steps can involve checking the security of the wiring harnesses and inspecting the bracket for any signs of wear or damage. Regular maintenance, such as ensuring the bracket and wiring are free from debris and corrosion, can help in maintaining the effectiveness of the bracket over time.

Compatibility and Applications

The 3651844 Wiring Retainer Bracket is designed for use in specific types of trucks and models. Its application is tailored to fit within the electrical systems of these vehicles, ensuring compatibility and optimal performance. Notable applications may include various commercial truck models where reliable wiring management is crucial.

Safety Considerations

When installing or maintaining the 3651844 Wiring Retainer Bracket, it is important to follow safety guidelines to prevent injuries or damage to the vehicle. This includes ensuring the electrical system is de-energized during installation and wearing appropriate personal protective equipment. Being aware of potential hazards, such as sharp edges or electrical shocks, and taking steps to mitigate them is crucial for safe handling of the bracket.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, with a history of innovation and quality in truck components. The company’s reputation is built on its commitment to producing reliable and efficient parts that contribute to the performance and safety of commercial vehicles. Cummins’ extensive range of products and services reflects its dedication to meeting the needs of the trucking industry.

Cummins Wiring Retainer Bracket 3651844 Compatibility

The Cummins Wiring Retainer Bracket part number 3651844 is a component designed to secure and organize wiring within the engine compartment. This part is engineered to fit seamlessly with several Cummins engine models, ensuring reliable performance and ease of maintenance.

QSK50 and CM2350 Engines

The QSK50 and CM2350 engines are part of Cummins’ heavy-duty diesel engine lineup, known for their robust construction and high performance. The Wiring Retainer Bracket 3651844 is specifically designed to integrate with these engines, providing a secure mounting point for wiring harnesses. This ensures that the wiring remains organized, reducing the risk of damage and improving overall system reliability.

K108 Engine

The K108 engine is another member of Cummins’ extensive engine family, often utilized in various industrial and commercial applications. The Wiring Retainer Bracket 3651844 is engineered to fit the K108 engine, offering a precise and durable solution for managing wiring within the engine compartment. This bracket helps maintain the integrity of the electrical system, contributing to the engine’s operational efficiency and longevity.

Grouping for Ease of Maintenance

When working with the QSK50, CM2350, and K108 engines, the use of the Wiring Retainer Bracket 3651844 simplifies maintenance procedures. By providing a standardized mounting solution, technicians can quickly and efficiently manage wiring, reducing downtime and improving overall serviceability. This part’s compatibility across these engine models highlights Cummins’ commitment to offering cohesive and reliable components for their engine lineup.

Role of Part 3651844 Wiring Retainer Bracket in Engine Systems

The 3651844 Wiring Retainer Bracket is a component in maintaining the integrity and organization of wiring within engine systems. It ensures that wires are securely held in place, preventing them from coming into contact with moving parts or high-temperature areas, which could lead to damage or failure.

Integration with Aftercooler

In systems equipped with an aftercooler, the 3651844 Wiring Retainer Bracket plays a significant role. It secures the wiring that connects various sensors and control units to the aftercooler. This ensures that the wiring remains taut and organized, reducing the risk of chafing or abrasion against the aftercooler’s surface. Proper wiring management is vital for the accurate transmission of data from temperature and pressure sensors, which are critical for the aftercooler’s efficient operation.

Interaction with Air Crossover Connection

The air crossover connection in an engine system often involves complex wiring to manage the flow of air between different components. The 3651844 Wiring Retainer Bracket is used to secure the wiring that interfaces with the air crossover connection. This helps in maintaining a clean and organized wiring path, which is essential for the reliable operation of solenoids and actuators that control the air flow. Secure wiring ensures that these components receive consistent power and signals, leading to optimal performance of the air crossover system.

By effectively managing the wiring in these components, the 3651844 Wiring Retainer Bracket contributes to the overall reliability and efficiency of the engine system.

Conclusion

The 3651844 Wiring Retainer Bracket by Cummins is a vital component for the electrical systems of commercial trucks, ensuring the organization and security of wiring harnesses. Its durable construction, ease of installation, and compatibility with various Cummins engine models make it a reliable choice for maintaining the efficiency and safety of truck electrical systems. Regular maintenance and adherence to safety guidelines during installation are key to maximizing the benefits of this part.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.