This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

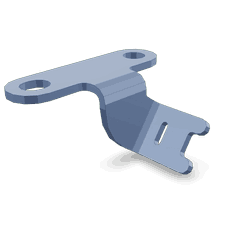

The Cummins 3651839 Wiring Retainer Bracket is a component designed to support and organize the wiring harnesses in commercial trucks. Its role is to ensure that the electrical wiring is securely held in place, which is vital for the proper operation and safety of the vehicle. This bracket contributes to the overall efficiency and reliability of the truck’s electrical system by maintaining the integrity of the wiring.

Purpose and Function

The primary purpose of the Wiring Retainer Bracket is to secure and organize the wiring harnesses within the truck’s electrical system. By doing so, it helps prevent damage to the wires from vibrations or physical contact with other components. This organization ensures that the electrical signals are transmitted efficiently, which is crucial for the operation of various truck systems. The bracket plays a role in maintaining the structural integrity of the wiring, which in turn supports the consistent performance of the truck’s electrical components 1.

Key Features

The Cummins 3651839 Wiring Retainer Bracket is characterized by its robust design and the materials used in its construction. It is typically made from durable materials that can withstand the harsh conditions often encountered in commercial trucking environments. The bracket’s design allows for easy attachment and adjustment, facilitating the secure placement of wiring harnesses. Additionally, it may include features such as corrosion resistance and flexibility in mounting options, which enhance its performance and longevity.

Benefits

The use of the Wiring Retainer Bracket offers several benefits. It improves wiring management by keeping the harnesses organized and protected, which can lead to a reduction in the risk of electrical issues. This organization and protection contribute to the enhanced safety and reliability of the truck’s electrical system. Moreover, by maintaining the integrity of the wiring, the bracket helps ensure that the electrical components of the truck operate efficiently and consistently 2.

Installation and Maintenance

Proper installation of the Wiring Retainer Bracket involves securing it in the designated location within the truck’s chassis, ensuring that it is firmly attached and aligned correctly with the wiring harnesses. Tools such as wrenches or screwdrivers may be required, depending on the specific design of the bracket. Routine maintenance includes inspecting the bracket for signs of wear or damage and ensuring that the wiring remains securely held in place. Regular checks can help identify potential issues before they lead to more significant problems.

Troubleshooting Common Issues

Common issues with the Wiring Retainer Bracket may include loose connections or damage to the bracket itself. If wiring appears to be coming loose, it may be necessary to re-secure it or adjust the bracket. In cases where the bracket is damaged, replacement may be required to ensure the continued protection and organization of the wiring harnesses. Regular inspections can help identify these issues early, allowing for timely repairs or replacements.

Role in Engine Systems

The 3651839 Wiring Retainer Bracket is an essential component in maintaining the integrity and organization of wiring systems within complex engine setups. Its application is particularly significant in conjunction with the aftercooler and air crossover connection.

Integration with Aftercooler

In systems equipped with an aftercooler, the 3651839 Wiring Retainer Bracket ensures that wiring harnesses are securely fastened and routed away from high-temperature and high-pressure areas. This bracket prevents wires from coming into contact with the aftercooler, which could lead to damage from heat or abrasion. Proper wiring management is key to maintaining the efficiency and reliability of the aftercooling process, which is vital for optimizing engine performance and durability 3.

Coordination with Air Crossover Connection

When dealing with air crossover connections, the 3651839 Wiring Retainer Bracket plays a role in organizing and protecting the wiring that interfaces with these components. The air crossover connection is a critical junction in the air intake system, often subject to vibrations and movement. The bracket helps to mitigate the risk of wire fatigue or breakage by providing a stable mounting point and reducing the strain on the wiring. This ensures consistent air flow management and prevents potential disruptions in the air supply to the engine, which could affect combustion efficiency and overall engine operation.

Manufacturer Information

Cummins Inc. is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industries. The company is known for its commitment to quality and innovation in the production of automotive components. Cummins’ history of delivering reliable and high-performance parts underscores its position as a trusted provider in the market. The Cummins 3651839 Wiring Retainer Bracket is a testament to the company’s dedication to enhancing the functionality and safety of commercial vehicles through well-designed and durable components.

Conclusion

The Cummins 3651839 Wiring Retainer Bracket is a vital component in the electrical systems of commercial trucks, ensuring the secure and organized placement of wiring harnesses. Its robust design and durable materials contribute to the efficiency, reliability, and safety of the truck’s electrical system. Proper installation, maintenance, and timely troubleshooting of this part are essential for the optimal performance of the vehicle.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Cummins Inc. Operation and Maintenance Manual for L9 CM2350 L120C, Bulletin Number 5504198.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.