3648723

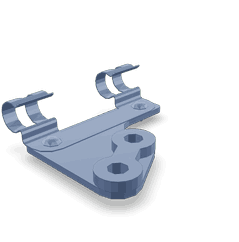

Wiring Retainer Bracket

Cummins®

AVAILABLE

10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3648723 Wiring Retainer Bracket is a component designed to secure and organize wiring harnesses within the electrical system of heavy-duty trucks. Its role is significant in maintaining the integrity and efficiency of the vehicle’s electrical components, ensuring they function reliably under demanding conditions.

Purpose and Function

The Wiring Retainer Bracket serves to hold wiring harnesses in place, preventing them from moving or becoming dislodged during operation. This function is vital for the consistent performance of the truck’s electrical system, as it helps to avoid issues such as short circuits or disconnections that could lead to system failures. By securing the wiring, the bracket contributes to the overall reliability and safety of the vehicle’s electrical components 1.

Key Features

This Cummins part is characterized by its robust design and material construction, which are intended to withstand the harsh environments typical of heavy-duty truck operations. It is engineered for durability, ensuring long-term performance, and is designed for ease of installation, accommodating various wiring configurations. Its compatibility with a range of systems makes it a versatile component for truck electrical systems 2.

Benefits

Utilizing the 3648723 offers several advantages. It enhances wire management by keeping harnesses organized and secured, which can reduce the risk of electrical faults. Additionally, by maintaining the integrity of the wiring system, it contributes to the enhanced longevity of electrical components, potentially reducing maintenance needs and downtime 3.

Installation Process

Installing the Wiring Retainer Bracket involves securing it in the designated location within the truck’s electrical system. It is important to follow manufacturer guidelines to ensure proper fit and function. Best practices include verifying the bracket’s compatibility with the existing wiring configuration and ensuring all connections are secure to prevent future issues.

Maintenance and Troubleshooting

To ensure the optimal performance of the Wiring Retainer Bracket, regular inspections are recommended to check for signs of wear or damage. Common issues may include bracket loosening or wiring wear, which can be addressed by re-securing the bracket or replacing damaged wiring as necessary. Proper maintenance helps to prevent electrical system failures and ensures the longevity of the component.

Compatibility and Applications

The 3648723 is designed for use in specific models and series of heavy-duty trucks, catering to a variety of electrical system configurations. Its application is tailored to meet the demands of these vehicles, ensuring compatibility and effective performance within the intended systems.

Safety Considerations

Properly installed and maintained wiring retainer brackets play a role in the safety of heavy-duty trucks by helping to prevent electrical fires and other hazards associated with unsecured or damaged wiring. Ensuring the bracket is correctly installed and regularly maintained is important for the safe operation of the vehicle.

Cummins Overview

Cummins Inc. is a leader in the design and manufacture of diesel engines, related technologies, and complete power solutions. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and efficient components for the automotive and heavy-duty truck industries. The company’s dedication to excellence is reflected in its wide range of products, including the 3648723.

Compatibility with Cummins Engines

The 3648723 is designed to be compatible with a range of Cummins engines, ensuring secure and organized wiring management. This bracket is essential for maintaining the integrity of the electrical system by keeping wiring neatly in place and preventing potential damage from movement or vibration.

QSK50 Engines

The QSK50 series, known for its robust performance and reliability, benefits from the 3648723. This bracket is engineered to fit seamlessly within the engine’s design, providing a stable mounting point for wiring harnesses. Its placement is critical in ensuring that the electrical connections remain intact and secure, which is vital for the engine’s optimal operation.

CM2350 Engines

The CM2350 engine series, recognized for its versatility and efficiency, also incorporates the 3648723. This bracket is specifically designed to align with the CM2350’s architecture, ensuring that wiring is held firmly in place. Its strategic positioning helps in maintaining the electrical system’s functionality, which is crucial for the engine’s performance and longevity.

K108 Engines

The K108 engine series, known for its durability and power, utilizes the 3648723 to manage its wiring effectively. This bracket is crafted to fit the unique layout of the K108 engine, providing a reliable solution for securing wiring. Its role in the engine’s electrical system is pivotal, as it helps prevent wiring from becoming dislodged, which could lead to operational issues.

By integrating the 3648723 into these engines, Cummins ensures that the electrical systems remain organized and protected, contributing to the overall reliability and efficiency of the engines.

Conclusion

The 3648723 Wiring Retainer Bracket is integral to maintaining the integrity and functionality of the wiring systems within Cummins engines. It is strategically positioned to secure and organize the wiring harnesses that connect various engine components, ensuring that they remain in place and are protected from potential damage due to vibrations or movement. This part contributes to the reliability and efficiency of the engine system by safeguarding the wiring that connects critical components, thereby supporting the overall performance and longevity of the engine.

-

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩ -

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.