This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

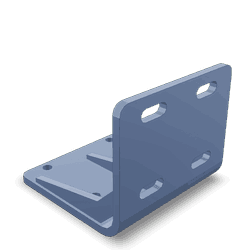

The Corrosion Resistor Bracket 3643878, manufactured by Cummins, is a component designed to enhance the durability and reliability of commercial trucks. Cummins, a well-established name in the automotive industry, is renowned for its robust and high-performance parts. This bracket is particularly significant in commercial truck applications, where resistance to environmental factors and mechanical stress is paramount 1.

Purpose and Function

The Corrosion Resistor Bracket 3643878 plays a role in supporting and securing various components within the truck’s engine system. It is typically positioned in areas exposed to harsh environmental conditions and mechanical vibrations. By providing a stable mounting point, it ensures that connected components remain securely in place, thereby contributing to the overall efficiency and safety of the vehicle 2.

Key Features

The design of the Corrosion Resistor Bracket 3643878 incorporates several features that enhance its functionality and longevity. Constructed from high-grade materials, it exhibits exceptional resistance to corrosion, which is crucial in environments where exposure to moisture and chemicals is common. Additionally, its robust construction allows it to withstand significant mechanical stress, ensuring long-term reliability 3.

Benefits

Utilizing the Corrosion Resistor Bracket 3643878 offers several advantages. Its corrosion-resistant properties reduce the likelihood of premature failure, leading to enhanced durability. This, in turn, minimizes the need for frequent replacements and maintenance, resulting in cost savings for fleet operators. Furthermore, the bracket’s reliable performance contributes to the overall efficiency and safety of the truck, ensuring optimal operation under various conditions.

Installation Considerations

Proper installation of the Corrosion Resistor Bracket 3643878 is vital to ensure its effectiveness. It is recommended to follow the manufacturer’s guidelines for installation, which may include specific torque settings and the use of compatible fasteners. Ensuring that the surface is clean and free from contaminants before installation will also contribute to a secure and lasting fit.

Troubleshooting Common Issues

While the Corrosion Resistor Bracket 3643878 is designed for durability, certain issues may arise over time. Common problems include corrosion in less protected areas and loosening of fasteners due to vibrations. Regular inspections can help identify these issues early. For corrosion, applying a protective coating may be beneficial. Loose fasteners should be re-tightened to the specified torque settings to maintain the bracket’s integrity.

Maintenance Tips

To ensure the longevity and effectiveness of the Corrosion Resistor Bracket 3643878, regular maintenance is recommended. This includes periodic inspections for signs of wear or corrosion, ensuring that all fasteners remain tight, and cleaning the bracket to remove any accumulated dirt or debris. Additionally, applying a corrosion-resistant coating can further protect the bracket from environmental factors.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality and innovation in the commercial truck industry. Their product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Corrosion Resistor Bracket 3643878 in Cummins Engines

The Corrosion Resistor Bracket 3643878, manufactured by Cummins, is an essential component designed to enhance the durability and longevity of specific engine models. This bracket is particularly integral in the QSK38 series engines, including the QSK38 CM2150 MCRS and QSK38 CM850 MCRS variants.

In these engines, the bracket plays a crucial role in protecting critical engine parts from corrosion. By providing a barrier against moisture and other corrosive elements, it helps maintain the structural integrity of the engine. The bracket is strategically placed to shield areas that are most susceptible to corrosion, ensuring that the engine operates efficiently and reliably over extended periods.

The design of the bracket is tailored to fit seamlessly within the engine architecture of the QSK38 series. Its placement and construction are optimized to provide maximum protection without interfering with other engine components. This ensures that the bracket not only serves its protective function but also integrates smoothly into the overall engine design.

The use of high-quality materials in the construction of the Corrosion Resistor Bracket 3643878 ensures that it can withstand the harsh operating conditions of these engines. This reliability is crucial for maintaining the performance and lifespan of the QSK38 CM2150 MCRS and QSK38 CM850 MCRS engines, making it a vital part of the engine’s maintenance and operational strategy.

Role of Part 3643878 Corrosion Resistor Bracket in Engine Systems

The Part 3643878 Corrosion Resistor Bracket is integral to the assembly and functionality of various engine components. It is specifically designed to resist corrosion, ensuring longevity and reliability in harsh environments.

Integration with Engine Components

-

Exhaust System: The bracket securely mounts the exhaust manifold to the engine block. Its corrosion-resistant properties prevent degradation from exhaust gases and heat, maintaining a stable connection.

-

Turbocharger Mounting: In turbocharged engines, the bracket is used to attach the turbocharger to the engine. This ensures that the turbocharger remains firmly in place, even under high stress and temperature conditions.

-

Heat Shield Attachment: The bracket is often employed to hold heat shields in place, protecting nearby components from excessive heat. Its resistance to corrosion ensures that the shield remains effective over time.

-

Sensor Mounting: Various sensors, such as oxygen sensors or temperature sensors, require stable mounting points. The bracket provides a reliable platform, safeguarding the sensors from environmental factors that could lead to corrosion.

-

Wiring Harness Support: In some engine configurations, the bracket supports wiring harnesses, keeping them organized and protected from physical damage and corrosion.

-

Accessory Mounting: Additional engine accessories, such as alternators or air conditioning compressors, may also utilize the bracket for secure attachment. This ensures that these components remain stable and function correctly.

The Part 3643878 Corrosion Resistor Bracket plays a significant role in maintaining the integrity and performance of these engine components by providing a durable and corrosion-resistant mounting solution.

Conclusion

The Corrosion Resistor Bracket 3643878 is a critical component in enhancing the durability and reliability of commercial trucks and specific engine models. Its corrosion-resistant properties, robust construction, and strategic placement within engine systems ensure long-term performance and efficiency. Proper installation, regular maintenance, and timely troubleshooting are essential to maximize the benefits of this Cummins part.

-

Thorsten Boger, Willard Cutler, Reducing Particulate Emissions in Gasoline Engines, SAE International, 2018.

↩ -

Tigran Parikyan Ed, Advances in Engine and Powertrain Research and Technology, Springer Nature, 2022.

↩ -

Allan Bonnick and Derek Newbold, A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition, Elsevier Ltd, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.