This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

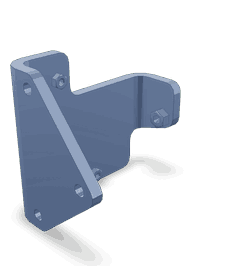

The Shock Absorber Bracket 3638475, manufactured by Cummins, is a component designed for heavy-duty truck suspension systems. Cummins, a well-established name in the commercial truck industry, is known for its commitment to quality and innovation. This bracket is integral to the suspension system, contributing to the overall performance and safety of heavy-duty trucks.

Basic Concepts of Shock Absorber Brackets

A shock absorber bracket serves as a mounting point for shock absorbers within a vehicle’s suspension system. Its function is to securely attach the shock absorber to the truck frame, allowing it to operate effectively. The bracket facilitates the transfer of forces between the shock absorber and the frame, which is crucial for the suspension’s ability to absorb road irregularities and maintain vehicle stability 1.

Purpose of the 3638475 Shock Absorber Bracket

The 3638475 Shock Absorber Bracket plays a role in the operation of a truck by supporting the shock absorber. It contributes to maintaining vehicle stability by ensuring the shock absorber is correctly positioned and functions as intended. This bracket enhances ride comfort by allowing the shock absorber to effectively dampen vibrations and absorb impacts from the road. Additionally, it ensures safety by helping to maintain proper wheel contact with the road surface, which is vital for handling and braking performance 2.

Key Features

The 3638475 Shock Absorber Bracket is characterized by its robust design and material selection. Constructed from high-strength materials, it is engineered to withstand the demanding conditions encountered by heavy-duty trucks. The bracket features precise mounting points that ensure accurate alignment of the shock absorber, which is critical for optimal suspension performance. Its design also incorporates features that enhance durability and resistance to wear, contributing to the longevity of the component 3.

Benefits

The advantages provided by the 3638475 Shock Absorber Bracket include improved handling due to the secure and precise mounting of the shock absorber. This leads to reduced wear on suspension components, as the shock absorber operates within its designed parameters. Additionally, the bracket contributes to the increased longevity of the shock absorbers by ensuring they are correctly aligned and supported, which is essential for their effective function 4.

Installation Process

Proper installation of the 3638475 Shock Absorber Bracket involves several steps. First, the necessary tools and replacement parts should be gathered. The truck should be securely supported, and the old bracket, if present, should be removed. The new bracket should be aligned with the mounting points on the truck frame and secured in place using the appropriate fasteners. Careful attention should be paid to ensuring the bracket is level and the shock absorber is correctly attached.

Troubleshooting Common Issues

Common problems associated with shock absorber brackets may include mounting bracket failure or misalignment. Diagnostic procedures should begin with a visual inspection of the bracket for signs of damage or wear. If misalignment is suspected, the bracket should be realigned and secured properly. In cases of failure, the bracket may need to be replaced to restore the suspension system’s integrity.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the 3638475 Shock Absorber Bracket. Inspection intervals should be established to check for signs of wear or damage. Any detected issues should be addressed promptly to prevent further deterioration. Keeping the bracket and its mounting points clean and free of debris will also contribute to its durability.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history rooted in innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes engines, filtration systems, and aftermarket parts, all of which are designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to quality and innovation is evident in its products, including the 3638475 Shock Absorber Bracket.

Shock Absorber Bracket 3638475 in Cummins Engines

The Shock Absorber Bracket 3638475 is a critical component in the Cummins QSK60 series engines, specifically designed to fit the QSK60 CM500 and QSK60 CM850 MCRS models. This part plays a pivotal role in the engine’s suspension system, ensuring that the shock absorbers are securely mounted and properly aligned.

In the QSK60 CM500 engine, the Shock Absorber Bracket 3638475 is engineered to maintain the integrity of the engine’s mounting system, providing stability and reducing vibrations. This is crucial for the engine’s performance and longevity, as it helps to absorb shocks and maintain a smooth operation.

Similarly, in the QSK60 CM850 MCRS engine, the Shock Absorber Bracket 3638475 is integral to the engine’s structural integrity. The MCRS variant, which is designed for marine applications, requires robust mounting solutions to withstand the harsh marine environment. This bracket ensures that the shock absorbers are effectively positioned to handle the unique stresses and vibrations encountered in marine settings.

Both engines benefit from the precision engineering of the Shock Absorber Bracket 3638475, which is designed to fit seamlessly into the engine’s architecture. This ensures that the shock absorbers function optimally, contributing to the overall reliability and performance of the engines.

Role of Part 3638475 Shock Absorber Bracket in Engine Systems

The part 3638475 Shock Absorber Bracket is integral to the efficient operation of various engine systems, particularly when interfacing with the drive and fan components.

Integration with the Drive System

In the drive system, the Shock Absorber Bracket serves to mitigate vibrations and shocks that are transmitted through the drive mechanism. By securely mounting the shock absorber to the engine frame, it ensures that the drive components, such as the belts and pulleys, operate smoothly without undue stress. This stability is essential for maintaining the precision and reliability of the drive system, which is responsible for transferring power from the engine to various auxiliary components.

Interaction with the Fan System

When it comes to the fan system, the Shock Absorber Bracket plays a significant role in enhancing the durability and performance of the fan assembly. The bracket absorbs the vibrations generated by the fan’s operation, which can be substantial due to the high-speed rotation and air resistance. This absorption helps in reducing wear and tear on the fan blades and the motor, leading to a longer service life for these components. Additionally, by stabilizing the fan, the bracket contributes to more consistent airflow, which is vital for effective engine cooling.

Overall, the Shock Absorber Bracket is a key component in ensuring that both the drive and fan systems within an engine operate efficiently and reliably, thereby contributing to the overall performance and longevity of the engine.

Conclusion

The 3638475 Shock Absorber Bracket is a vital component in the suspension systems of heavy-duty trucks, particularly those equipped with Cummins engines. Its robust design, precise mounting points, and integration with critical engine systems underscore its importance in maintaining vehicle stability, enhancing ride comfort, and ensuring safety. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part, contributing to the overall performance and longevity of the vehicle.

-

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

The Automotive Body, Frederick F. Ling, Springer Science, 2011

↩ -

Brake Design and Safety, Third Edition, Rudolf Limpert, SAE International, 2011

↩ -

Combustion Engine Diagnosis, Rolf Isermann, Springer Vieweg, 2017

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.