This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

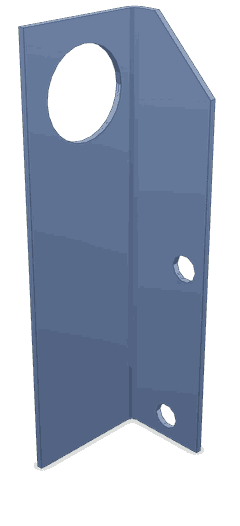

The Cummins 3635081 Wiring Retainer Bracket is designed to secure and organize wiring harnesses in heavy-duty trucks. This component is crucial for maintaining the integrity and reliability of the truck’s electrical system. By ensuring wires are properly managed and protected, the Wiring Retainer Bracket contributes to the overall performance and safety of the vehicle.

Purpose and Function

The primary role of the Wiring Retainer Bracket is to secure and organize wiring harnesses within the electrical system of heavy-duty trucks. It prevents wires from coming into contact with moving parts or sharp edges, which could lead to damage. By keeping the wiring organized, it ensures reliable electrical connections, which are vital for the proper functioning of various truck systems. This component helps in reducing the risk of electrical faults and enhances the durability of the wiring system 1.

Key Features

The design of the Cummins 3635081 incorporates several features that enhance its functionality and ease of use. It is constructed from durable materials to withstand the harsh conditions typically encountered in heavy-duty truck environments. The bracket is designed for straightforward installation, allowing for quick and efficient setup. Additionally, it is compatible with various wiring configurations, making it a versatile solution for different truck models 2.

Benefits

Utilizing the Cummins 3635081 offers several advantages. It contributes to improved reliability of the electrical system by securing wires and preventing damage. This results in a reduced risk of electrical issues, which can lead to downtime or safety hazards. Furthermore, by maintaining organized and protected wiring, the bracket supports enhanced overall truck performance and longevity 3.

Installation Process

Installing the Wiring Retainer Bracket involves several steps to ensure it is securely and effectively placed within the truck’s electrical system. Begin by identifying the appropriate location for the bracket, ensuring it is positioned to adequately support the wiring harnesses. Next, attach the bracket to the truck’s frame or designated mounting point using the provided fasteners. Once secured, route the wiring harnesses through the bracket, ensuring they are neatly organized and protected. Finally, double-check the installation to confirm that the wiring is properly supported and that there are no loose connections.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the Wiring Retainer Bracket, regular maintenance is recommended. Inspect the bracket periodically for signs of wear or damage, and ensure that the wiring remains securely fastened. Common issues may include loose connections or damaged wires, which can be addressed by re-securing the wiring or replacing damaged sections as necessary. Following these guidelines will help maintain the effectiveness of the bracket and the electrical system it supports.

Safety Considerations

When installing or maintaining the Wiring Retainer Bracket, it is important to observe several safety guidelines. Ensure that the truck’s electrical system is powered down to prevent the risk of electrical shock. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Additionally, follow all manufacturer instructions and recommendations to ensure a safe and effective installation process.

Cummins Overview

Cummins Inc. is a renowned manufacturer of diesel engines and related technologies, with a history of innovation and commitment to quality. The company has established a strong reputation in the automotive industry for producing reliable and high-performance components. Cummins’ dedication to excellence is evident in their range of products, including the 3635081 Wiring Retainer Bracket, which is designed to meet the demanding requirements of heavy-duty truck applications.

Cummins Wiring Retainer Bracket 3635081 in Engine Applications

The Cummins Wiring Retainer Bracket part number 3635081 is a critical component in the electrical system of certain Cummins engines. This bracket is designed to secure and organize wiring harnesses, ensuring that electrical connections remain stable and protected from vibrations and other potential disruptions.

K38 and K50 Engines

In the K38 and K50 engine series, the Wiring Retainer Bracket 3635081 plays a vital role in maintaining the integrity of the engine’s electrical architecture. These engines, known for their robust performance and reliability, benefit from the precise fit and function of this bracket. It helps to keep the wiring neatly arranged, which is essential for the efficient operation of the engine’s electronic control systems.

Grouping of Engines

The K38 and K50 engines, while distinct in their specific applications and configurations, share common design elements that make the Wiring Retainer Bracket 3635081 a suitable fit for both. This commonality allows for streamlined maintenance and repair processes, as technicians can use the same part across multiple engine models within this series.

The bracket’s design ensures it can adapt to the unique spatial requirements of each engine, providing a secure mounting point for the wiring harness. This adaptability is crucial in environments where engines are subject to varying conditions and operational demands.

By using the Wiring Retainer Bracket 3635081, technicians and operators can ensure that the electrical systems in these engines remain reliable and efficient, contributing to the overall performance and longevity of the engines.

Role of Part 3635081 Wiring Retainer Bracket in Engine Systems

The wiring retainer bracket, identified by part number 3635081, is an integral component in the organization and protection of engine wiring systems. It is strategically positioned to secure and manage the wiring harness, ensuring that the wires remain in place and are protected from potential damage caused by engine vibrations, heat, and moving parts.

Integration with the Wiring Harness

The primary function of the 3635081 wiring retainer bracket is to hold the wiring harness in a fixed position. This is essential for maintaining the integrity of the electrical connections and preventing wires from coming into contact with hot engine components or sharp edges. By securing the harness, the bracket helps to reduce the risk of electrical shorts and ensures consistent performance of the engine’s electrical systems.

Protection and Organization

In addition to securing the harness, the wiring retainer bracket plays a significant role in protecting the wiring from environmental factors. Engine compartments are often exposed to extreme temperatures, moisture, and debris. The bracket acts as a barrier, shielding the wires from these elements and prolonging the lifespan of the wiring system.

Furthermore, the bracket contributes to the overall organization of the engine bay. By keeping the wiring neatly arranged, it allows for easier access during maintenance and repairs. This organization also aids in the efficient routing of wires, reducing the likelihood of tangling and simplifying the installation process of new components.

Enhanced Safety and Reliability

The use of the 3635081 wiring retainer bracket enhances the safety and reliability of the engine system. Secure wiring reduces the chances of unexpected failures, which can be particularly dangerous in high-stress environments. Additionally, well-organized and protected wiring contributes to the overall efficiency of the engine, ensuring that electrical components operate within their specified parameters.

Conclusion

The Cummins 3635081 Wiring Retainer Bracket is a vital component in the engine system, providing essential support and protection for the wiring harness. Its role in maintaining order, safeguarding wires, and enhancing system reliability underscores its importance in the functioning of modern engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.