This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

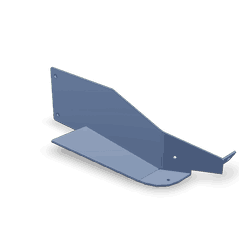

The 3632730 Wiring Retainer Bracket, manufactured by Cummins, is a component designed to enhance the electrical system’s integrity in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces this bracket to ensure the efficient and safe operation of truck electrical systems. The significance of this part lies in its role in maintaining the organization and protection of wiring harnesses, which are vital for the truck’s electrical performance 1.

Basic Concepts of Wiring Retainer Brackets

A Wiring Retainer Bracket serves as a structural component in vehicle electrical systems. Its primary function is to secure and organize wiring harnesses, preventing them from moving or becoming damaged during vehicle operation. Proper wiring management is crucial in trucks, where the electrical system supports various functions, from engine operation to lighting and communication systems. Effective wiring management contributes to the overall reliability and safety of the vehicle 2.

Purpose of the 3632730 Wiring Retainer Bracket

The 3632730 Wiring Retainer Bracket plays a role in the operation of a truck by securing and organizing wiring harnesses. This function is important for preventing damage to the wires, which can occur from vibrations or contact with other components. By keeping the wiring harnesses in place, the bracket helps ensure efficient electrical performance and reduces the risk of electrical faults that could affect the truck’s operation 3.

Key Features

The 3632730 Wiring Retainer Bracket is constructed from materials chosen for their durability and resistance to the harsh conditions found in commercial truck environments. Its design includes features that enhance its functionality, such as secure mounting points and a structure that allows for easy access to the wiring harnesses for maintenance or repairs. These attributes contribute to the bracket’s effectiveness in protecting and organizing the wiring system.

Benefits

The use of the 3632730 Wiring Retainer Bracket offers several benefits. It contributes to improved electrical system reliability by securing the wiring harnesses and protecting them from damage. This, in turn, reduces the risk of wire damage and enhances the overall performance and safety of the truck. The bracket’s design and construction also ensure that it can withstand the demanding conditions of commercial truck operations, providing long-term value and reliability.

Installation Considerations

When installing the 3632730 Wiring Retainer Bracket, it is important to follow guidelines and best practices to ensure proper fitting and functionality. This may involve using specific tools or additional components to secure the bracket in place. Careful attention to the installation process helps ensure that the bracket effectively performs its intended function, contributing to the truck’s electrical system’s reliability and safety.

Troubleshooting and Maintenance

Common issues with Wiring Retainer Brackets may include damage from physical impact or wear over time. Diagnosing problems with the bracket involves inspecting it for signs of damage or wear and ensuring that it is securely mounted. Maintenance tips for prolonging the life and effectiveness of the 3632730 Wiring Retainer Bracket include regular inspections for damage and ensuring that it remains securely attached to the truck’s structure.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the commercial truck industry, with a history of producing reliable and high-quality components. Their reputation is built on a commitment to innovation, quality, and customer satisfaction. Cummins offers a wide range of products beyond the 3632730 Wiring Retainer Bracket, including engines, filtration systems, and aftermarket parts, all designed to meet the demanding needs of commercial truck operations.

Role of Part 3632730 Wiring Retainer Bracket in Engine Systems

The 3632730 Wiring Retainer Bracket is an essential component in organizing and securing wiring within engine systems. It works in conjunction with several other components to ensure efficient and safe operation of the engine.

Integration with Harness Mounting Kit and Wiring Harness Mounting Kit

When combined with a Harness Mounting Kit or a Wiring Harness Mounting Kit, the Wiring Retainer Bracket provides a structured framework for the wiring. This setup helps in maintaining the integrity of the wiring by preventing tangling and reducing the risk of damage from vibrations or movement. The bracket ensures that the wiring remains in place, which is particularly important in high-vibration environments typical of engine compartments.

Use in Electronic Engine Systems

In electronic engine systems, the Wiring Retainer Bracket plays a significant role in managing the complex network of wires that connect various sensors, actuators, and control units. By securing the wiring, it helps maintain consistent electrical connections, which is vital for the accurate functioning of electronic engine controls.

Application in Engine Monitor and Electronic Engine Mount

When integrated with an Engine Monitor or an Electronic Engine Mount, the Wiring Retainer Bracket ensures that the monitoring systems receive uninterrupted power and data signals. This is important for real-time monitoring of engine performance and diagnostics, allowing for timely detection of issues and efficient maintenance.

Compatibility with AEM Harness

For systems utilizing an AEM Harness, the Wiring Retainer Bracket offers a reliable method to keep the harness organized and protected. This is particularly beneficial in custom or high-performance engine builds where the wiring may be more exposed to environmental factors.

Role in Cense Upfit and Monitor Systems

In applications involving a Cense Upfit or additional Monitor systems, the Wiring Retainer Bracket helps in managing the increased wiring complexity. It ensures that all additional sensors and monitoring equipment are properly wired and secured, contributing to the overall reliability and performance of the engine system.

General Mounting Applications

Across various Mounting applications, whether it be for standard engine mounts or specialized setups, the Wiring Retainer Bracket provides a consistent and secure method for wiring management. This is essential for both the initial installation and any future maintenance or upgrades to the engine system.

Conclusion

The 3632730 Wiring Retainer Bracket by Cummins is a vital component in the electrical systems of commercial trucks, ensuring the organization and protection of wiring harnesses. Its robust design and integration with various engine systems contribute to the reliability and safety of the vehicle’s electrical performance. Proper installation, maintenance, and understanding of its role in engine systems are crucial for maximizing its benefits and ensuring the efficient operation of the truck.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.