This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

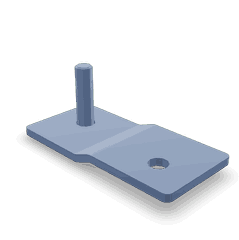

The Cummins 3632430 Vibration Isolator Bracket is a component designed to enhance the operational efficiency of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems aimed at improving truck performance and reliability. This part is significant in this context as it plays a role in mitigating the vibrations that can affect the overall performance and longevity of heavy-duty trucks.

Basic Concepts of Vibration Isolator Brackets

A Vibration Isolator Bracket is a component used in vehicles to reduce the transmission of vibrations from the engine and drivetrain to the truck’s frame and cabin. By isolating these vibrations, the bracket helps maintain a smoother operation, which can lead to improved ride comfort and reduced wear on various truck components. The bracket achieves this by providing a flexible mounting point that absorbs and dampens vibrations, preventing them from being transmitted throughout the vehicle 1.

Purpose of the 3632430 Vibration Isolator Bracket

The 3632430 Vibration Isolator Bracket is specifically designed to reduce engine and drivetrain vibrations in trucks. Its role is to provide a stable yet flexible mounting solution that allows for the natural movement of the engine while minimizing the impact of vibrations on the truck’s structure. This reduction in vibration contributes to a more comfortable ride for the driver and passengers, as well as protecting the truck’s components from premature wear and potential damage 2.

Key Features

The 3632430 Vibration Isolator Bracket features a robust design that includes a combination of materials to ensure durability and effectiveness. It is constructed from high-quality rubber and metal components, which work together to provide the necessary flexibility and strength. The design incorporates specific mounting points and attachment mechanisms that ensure a secure fit and optimal performance. Additionally, the bracket is engineered to withstand the harsh conditions often encountered in commercial truck operations, ensuring long-lasting reliability.

Benefits

The use of the 3632430 Vibration Isolator Bracket offers several benefits. It contributes to improved ride comfort by reducing the vibrations felt by the driver and passengers. Additionally, by minimizing the transmission of vibrations to the truck’s frame and components, it helps reduce wear on these parts, potentially extending their lifespan. Furthermore, the bracket plays a role in enhancing the overall performance of the truck by ensuring that the engine operates in a stable environment, free from excessive vibrations 3.

Installation Process

Installing the 3632430 Vibration Isolator Bracket requires careful attention to ensure a secure and effective fit. The process involves removing the old bracket, if present, and cleaning the mounting area to ensure a smooth surface. The new bracket is then positioned according to the manufacturer’s guidelines, using the provided mounting hardware to secure it in place. It is important to use the correct tools and follow best practices to ensure that the bracket is installed correctly and functions as intended.

Troubleshooting Common Issues

Common issues with Vibration Isolator Brackets can include excessive vibration, which may indicate a problem with the bracket’s installation or condition. If vibrations persist after installation, it is advisable to check the mounting points for proper alignment and security. Additionally, inspecting the bracket for signs of wear or damage can help identify any issues that may be contributing to the problem. Addressing these issues promptly can help maintain the effectiveness of the bracket and the overall performance of the truck.

Maintenance Tips

Regular maintenance of the 3632430 Vibration Isolator Bracket is important to ensure its longevity and optimal performance. This includes periodic inspections to check for signs of wear, damage, or misalignment. Any issues identified during these inspections should be addressed promptly to prevent further deterioration. Additionally, ensuring that the bracket remains securely mounted and that the surrounding components are in good condition can help maintain the effectiveness of the vibration isolation system.

Compatibility and Applications

The 3632430 Vibration Isolator Bracket is designed for use in specific types of trucks and engines. It is important to verify compatibility with the truck’s make, model, and engine type to ensure proper fit and function. Cummins provides detailed information on the compatibility of this bracket with various truck models and series, ensuring that it can be effectively integrated into the intended applications.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes a variety of engines, components, and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Cummins Vibration Isolator Bracket 3632430 Compatibility

The Cummins Vibration Isolator Bracket, part number 3632430, is a component designed to mitigate engine vibrations and enhance the longevity of various engine systems. This part is engineered to fit seamlessly with specific Cummins engines, ensuring optimal performance and reliability.

K38 Engines

The K38 engine series benefits significantly from the installation of the 3632430 Vibration Isolator Bracket. This bracket is specifically designed to interface with the K38’s unique mounting points and structural design, providing a robust solution to vibration issues. By effectively isolating the engine from excessive vibrations, it helps maintain the integrity of engine mounts and related components, thereby extending the overall lifespan of the engine.

K50 Engines

Similarly, the K50 engine series is another beneficiary of the 3632430 Vibration Isolator Bracket. This bracket is tailored to fit the K50’s specific architecture, ensuring that it can effectively manage the vibrations generated by the engine. The precise engineering of the bracket allows it to absorb and dissipate vibrations, reducing the strain on engine mounts and other critical components. This results in a smoother operation and improved durability of the engine.

Grouping Considerations

While the 3632430 Vibration Isolator Bracket is designed to fit both the K38 and K50 engines, it is essential to note that the bracket’s design and mounting specifications are tailored to each engine series. This ensures that the bracket provides the best possible performance and compatibility with the specific engine it is intended for. Therefore, it is crucial to use the correct bracket for the respective engine to achieve the desired vibration isolation and longevity benefits.

Role of Part 3632430 Vibration Isolator Bracket in Engine Systems

The Part 3632430 Vibration Isolator Bracket is integral to maintaining the stability and efficiency of various engine components. When integrated into an engine system, this bracket effectively mitigates vibrations that can arise from the operation of the engine and its ancillary components.

In an engine arrangement, the Vibration Isolator Bracket is typically positioned to support and stabilize the alternator. The alternator, a key component responsible for generating electrical power to charge the battery and power the vehicle’s electrical systems, operates at high speeds. This high-speed operation can generate significant vibrations, which, if not properly managed, can lead to increased wear and potential failure of the alternator and other nearby components.

The Vibration Isolator Bracket is designed to absorb and dampen these vibrations, ensuring that the alternator operates smoothly and efficiently. It achieves this by providing a secure yet flexible mounting point for the alternator, allowing it to function without transmitting excessive vibrations to the engine block or other parts of the vehicle.

Additionally, the bracket often interacts with the alternator guard. The alternator guard is a protective cover that shields the alternator from debris, moisture, and other environmental factors that could impair its performance. The Vibration Isolator Bracket ensures that the guard remains in the correct position, maintaining its effectiveness while still allowing for the necessary flexibility to accommodate the vibrations from the alternator.

In summary, the Part 3632430 Vibration Isolator Bracket plays a significant role in enhancing the durability and performance of the alternator and its associated components by effectively managing vibrations within the engine system.

Conclusion

The 3632430 Vibration Isolator Bracket by Cummins is a critical component in the maintenance and enhancement of commercial truck performance. By effectively managing engine and drivetrain vibrations, this part contributes to improved ride comfort, reduced component wear, and extended engine lifespan. Its robust design, compatibility with specific Cummins engines, and the role it plays in stabilizing key engine components underscore its importance in the commercial truck industry.

-

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.