3631336

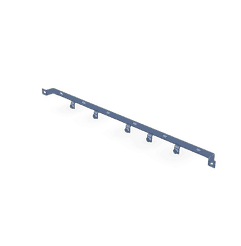

Wiring Retainer Bracket

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Wiring Retainer Bracket, part number 3631336, is a component designed for the management of wiring harnesses in commercial trucks. Cummins, a well-established name in the automotive industry, produces this bracket to enhance the organization and protection of electrical wiring within trucks. Effective wiring management is vital for the reliable operation of a truck’s electrical system, ensuring that all components function correctly and safely 1.

Function and Operation

This Cummins part operates by securing and organizing the wiring harnesses within a truck’s electrical system. It plays a role in preventing wires from coming into contact with moving parts or sharp edges, which could lead to damage. By keeping the wiring organized, it also aids in the efficient routing of electrical signals, contributing to the overall performance and reliability of the truck’s electrical system 2.

Key Features

The Wiring Retainer Bracket 3631336 is constructed from durable materials, ensuring it can withstand the harsh conditions often encountered in commercial trucking environments. Its design includes features that allow for easy attachment and adjustment, facilitating a secure fit around the wiring harnesses. Additionally, the bracket is engineered to accommodate various wire sizes and configurations, providing versatility in its application 3.

Benefits of Using the Wiring Retainer Bracket

Incorporating the Wiring Retainer Bracket 3631336 into truck maintenance routines offers several advantages. It improves wire management by keeping harnesses organized and protected, which can reduce the risk of electrical faults. This, in turn, enhances the safety and reliability of the truck’s electrical system, potentially leading to fewer breakdowns and maintenance issues 4.

Installation and Compatibility

Proper installation of the Wiring Retainer Bracket is key to its effectiveness. It is designed to be compatible with a range of truck models and electrical systems, though it is important to verify compatibility before installation. Following the manufacturer’s guidelines ensures that the bracket is securely and correctly installed, maximizing its benefits 5.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the Wiring Retainer Bracket, regular maintenance is recommended. This includes checking for signs of wear or damage and ensuring that the bracket remains securely attached. Common issues may include loose connections or damage to the bracket itself, which can often be addressed through re-securing or replacing the bracket as necessary.

Safety Considerations

When working with electrical components, including the Wiring Retainer Bracket, it is important to observe safety practices to prevent electrical shocks and ensure safe operation. This includes ensuring the truck’s electrical system is de-energized before beginning work and using appropriate personal protective equipment.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history of innovation and commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for various applications.

Cummins Wiring Retainer Bracket 3631336 Compatibility

The Cummins Wiring Retainer Bracket, part number 3631336, is designed to secure and organize the wiring harness in various engine configurations. This bracket ensures that the electrical connections remain stable and protected, preventing potential damage from movement or vibration.

K50 Series Engines

In the K50 series engines, the Wiring Retainer Bracket 3631336 is integral to maintaining the integrity of the electrical system. This bracket is specifically engineered to fit the unique layout and design of the K50 engines, ensuring that the wiring harness is properly supported and secured. The bracket’s design allows for easy installation and adjustment, accommodating the specific wiring configurations required by these engines.

Grouping by Application

The Wiring Retainer Bracket 3631336 is not limited to a single engine model but is compatible with a range of Cummins engines. Its design allows it to be used across various engine groups, providing a versatile solution for securing wiring harnesses. This compatibility is particularly beneficial for fleets and operators who use multiple engine models, as it simplifies maintenance and repair processes by using a standardized part.

Installation Considerations

When installing the Wiring Retainer Bracket 3631336, it is essential to follow the manufacturer’s guidelines to ensure proper fit and function. The bracket should be positioned in a way that it effectively supports the wiring harness without obstructing other engine components. Proper installation is crucial for maintaining the electrical system’s reliability and preventing potential issues that could arise from loose or damaged wiring.

Role of Part 3631336 Wiring Retainer Bracket in Engine Systems

The 3631336 Wiring Retainer Bracket is a component in organizing and securing wiring within various engine systems. Its primary function is to maintain the integrity and order of the wiring harness, ensuring that wires remain in their designated paths and do not interfere with other components or become damaged during engine operation.

Integration with Engine Components

-

Wiring Harness: The Wiring Retainer Bracket is strategically positioned along the wiring harness to hold wires in place. This prevents tangling and reduces the risk of wires coming into contact with moving parts or high-temperature areas within the engine compartment.

-

Electronic Engine Systems: In electronic engine systems, where precise wiring placement is vital for proper function, the Wiring Retainer Bracket ensures that sensors, actuators, and other electronic components receive consistent and reliable signals. This is particularly important in systems where real-time data is critical for engine performance and diagnostics.

-

Engine Monitor: When integrated with an engine monitor system, the Wiring Retainer Bracket helps maintain the accuracy of sensor readings by keeping wires away from heat sources and vibration-prone areas. This ensures that the engine monitor receives clean, uninterrupted data, allowing for precise engine diagnostics and performance monitoring.

-

Mounting Systems: The bracket is often used in conjunction with mounting systems to secure wiring in place. This is especially important in applications where the engine undergoes significant movement or vibration, such as in automotive or aerospace applications. Proper mounting ensures that the wiring remains intact and functional under various operating conditions.

-

Cense Upfit: In cense upfit applications, where additional sensors or monitoring equipment is installed, the Wiring Retainer Bracket plays a key role in managing the increased wiring complexity. It helps in organizing new wires alongside existing ones, ensuring that the upfit does not compromise the original wiring integrity.

-

Cense Harness: The bracket is also utilized within the cense harness to maintain the structural integrity of the harness. By securing wires at regular intervals, it prevents sagging or shifting, which could lead to connectivity issues or increased wear on the wiring.

Conclusion

The 3631336 Wiring Retainer Bracket is a fundamental component in maintaining the organization, safety, and functionality of wiring within engine systems. Its role in securing and managing wires ensures that engine components operate efficiently and reliably. Proper installation, maintenance, and adherence to safety practices are essential for maximizing the benefits of this part.

-

MJ Nunney, Light and Heavy Vehicle Technology, Fourth Edition, Butterworth-Heinemann, 2007.

↩ -

Moustafa ElGindy and Zeinab ElSayegh, Road and Off-Road Vehicle Dynamics, Springer Nature, 2023.

↩ -

Gang Sheng, Vehicle Noise, Vibration and Sound Quality, SAE International, 2012.

↩ -

Dominique Bonneau, Aurelian Fatu and Dominique Souchet, Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Wiley-ISTE, 2014.

↩ -

QSB4.5 CM2350 B174C, Service Manual (5613383).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.