This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

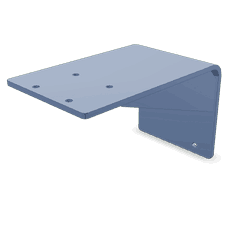

The Corrosion Resistor Bracket 3630903 is a component designed by Cummins, a well-established manufacturer in the automotive and heavy-duty truck industry. This bracket is specifically engineered to enhance the durability and functionality of truck components by providing resistance to corrosion. Its role is significant in environments where trucks are exposed to harsh conditions, ensuring that the structural integrity of the components it supports is maintained over time 1.

Purpose and Function

The Corrosion Resistor Bracket 3630903 plays a role in the operation of a truck by securing and supporting various components that are susceptible to corrosion. By doing so, it contributes to the overall functionality and longevity of the truck’s parts. This bracket is integral in maintaining the alignment and stability of components, which is vital for the efficient operation of the vehicle 2.

Key Features

The primary features of the Corrosion Resistor Bracket 3630903 include its material composition, which is designed to resist corrosion effectively. The bracket is typically made from high-quality materials that offer superior durability. Its design elements are tailored to provide a secure fit and easy installation, while any unique characteristics enhance its performance in demanding environments 3.

Benefits

The advantages provided by the Corrosion Resistor Bracket 3630903 include improved resistance to corrosion, which helps in maintaining the structural integrity of the components it supports. This enhanced durability can lead to potential cost savings over time, as the need for frequent replacements or repairs is reduced. Additionally, the bracket contributes to the overall reliability and performance of the truck 4.

Installation Considerations

For the proper installation of the Corrosion Resistor Bracket 3630903, it is important to follow guidelines and best practices. This may include ensuring the surface is clean and free from corrosion before installation, using the correct fasteners, and verifying that the bracket is securely attached. Taking these precautions can help in achieving a successful installation and ensuring the bracket functions as intended 1.

Maintenance and Troubleshooting

Routine maintenance of the Corrosion Resistor Bracket 3630903 is recommended to ensure its longevity and effectiveness. This may involve periodic inspections for signs of wear or corrosion, and cleaning the bracket as necessary. Common issues that may arise include loosening of fasteners or corrosion in areas not adequately protected. Suggested troubleshooting steps include tightening fasteners and applying a corrosion-resistant coating if needed 2.

Environmental and Operational Context

Environmental factors and operational conditions can affect the performance of the Corrosion Resistor Bracket 3630903. Exposure to moisture, salt, and other corrosive elements can challenge the bracket’s effectiveness. Strategies for mitigating these challenges include regular maintenance, applying protective coatings, and ensuring the bracket is installed in a manner that minimizes exposure to corrosive elements 3.

Cummins Overview

Cummins is a reputable manufacturer with a long-standing history in the industry. Known for its commitment to quality and innovation, Cummins has established a strong reputation for producing reliable and durable truck components. The company’s dedication to excellence is reflected in its product line, including the Corrosion Resistor Bracket 3630903, which is designed to meet the demanding requirements of heavy-duty truck applications 4.

Compatibility of 3630903

The 3630903 bracket is specifically designed to fit seamlessly with several Cummins engine models. These engines are known for their durability and efficiency, making the corrosion resistor bracket an essential part of their maintenance and operational integrity.

-

K38 Series Engines: The 3630903 bracket is compatible with the K38 series engines. This series is renowned for its robust construction and reliability, often used in heavy-duty applications. The bracket’s design ensures it can withstand the harsh conditions these engines operate under, providing a stable mounting point that resists corrosion.

-

Other Cummins Engines: While the primary focus is on the K38 series, the 3630903 bracket is also designed to fit other Cummins engines. Its universal design allows it to be used across various models, ensuring that the bracket provides the necessary support and corrosion resistance in different engine configurations.

Importance of the Corrosion Resistor Bracket

The corrosion resistor bracket plays a vital role in protecting engine components from the damaging effects of corrosion. By providing a stable mounting point, it helps maintain the structural integrity of the engine, reducing the risk of failures due to material degradation. This is particularly important in environments where engines are exposed to moisture, chemicals, or other corrosive elements.

Installation and Maintenance

Proper installation of the 3630903 bracket is crucial to ensure its effectiveness. Technicians should follow the manufacturer’s guidelines to ensure the bracket is securely fastened and positioned correctly. Regular maintenance checks should be conducted to inspect the bracket for signs of wear or corrosion, ensuring it continues to perform its intended function.

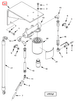

Integration of Part 3630903 Corrosion Resistor Bracket in Engine Systems

When integrating the Corrosion Resistor Bracket into engine systems, it is essential to understand its role in conjunction with other components. This bracket is designed to securely hold the corrosion resistor head in place, ensuring stable and reliable operation within the engine’s electrical system.

Interaction with Corrosion Resistor Head

The corrosion resistor head is a key component that manages electrical resistance to prevent corrosion in critical engine parts. The 3630903 bracket provides a robust mounting solution, allowing the head to be positioned accurately and remain fixed during engine operation. This ensures consistent performance and longevity of the resistor head.

Coordination with Corrosion Resistor Mounting

Effective corrosion resistor mounting is vital for the overall integrity of the engine’s electrical components. The 3630903 bracket enhances this mounting by offering a corrosion-resistant surface that protects the resistor from environmental factors. This integration helps maintain the electrical balance and efficiency of the engine system.

Support for Resistor Functionality

The resistor plays a significant role in regulating electrical current within the engine. The 3630903 bracket supports this function by providing a secure attachment point that withstands vibrations and thermal expansions. This stability is essential for the resistor to operate within specified parameters, ensuring optimal engine performance.

Comprehensive Corrosion Protection

Incorporating the 3630903 bracket into the engine system enhances overall corrosion protection. By securely holding the corrosion resistor components in place, it contributes to a more reliable and durable electrical system. This integration is particularly beneficial in environments where corrosion can significantly impact engine longevity and efficiency.

Conclusion

The Corrosion Resistor Bracket 3630903 is a critical component in the maintenance and operation of Cummins engines, particularly in harsh environments where corrosion is a significant concern. Its design and material composition are tailored to provide superior durability and resistance to corrosion, ensuring the structural integrity and longevity of engine components. Proper installation and regular maintenance are essential to maximize the benefits of this part, contributing to the overall reliability and performance of the engine system.

-

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ ↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ ↩ -

Calder, N. (2007). Diesel Engine Care and Repair. The McGraw-Hill Companies.

↩ ↩ -

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.