This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3630777 Wiring Retainer Bracket is a component designed to secure and organize wiring harnesses within the engine compartment of commercial trucks. Its role in the electrical system is to maintain the integrity and efficiency of the wiring, ensuring that electrical connections remain secure and protected from environmental factors 1.

Purpose and Function

The Wiring Retainer Bracket serves to hold wiring harnesses in place, preventing them from moving or becoming dislodged during operation. This bracket contributes to the overall efficiency and safety of the electrical system by reducing the risk of wire chafing, which can lead to electrical faults 3. It also helps in maintaining a tidy engine compartment, which is beneficial for both maintenance and inspection purposes.

Key Features

The design of the 3630777 Wiring Retainer Bracket incorporates durable materials that offer resistance to corrosion, ensuring longevity in various operating conditions. It is engineered to be compatible with a range of wiring configurations, providing flexibility in its application across different truck models. The bracket’s construction allows for easy adjustment and secure fastening of wiring harnesses.

Benefits

Utilizing the Cummins 3630777 Wiring Retainer Bracket offers several advantages. It enhances wire management within the engine compartment, which can lead to improved system reliability. By securing the wiring, it reduces the likelihood of electrical faults that may arise from loose or damaged wires. Additionally, the bracket contributes to the enhanced longevity of electrical components by protecting them from physical damage and environmental exposure 2.

Installation Process

Installing the Wiring Retainer Bracket involves securing it in the designated location within the truck’s engine bay. It is important to follow the manufacturer’s guidelines for proper placement and fastening. Ensuring that the bracket is correctly installed will contribute to the effectiveness of wire management and the overall safety of the electrical system.

Maintenance and Troubleshooting

Regular inspection of the Wiring Retainer Bracket is recommended to ensure it remains in good condition and properly secured. Common issues may include corrosion or damage to the bracket, which can be addressed through cleaning or replacement as necessary. It is also important to check that the wiring harnesses are correctly fastened and not showing signs of wear or damage.

Safety Considerations

When working with electrical components and the Wiring Retainer Bracket, it is important to adhere to safety guidelines. This includes ensuring that the truck’s electrical system is de-energized before beginning any work. Taking precautions to avoid electrical shocks or damage to the system is crucial for personal safety and the integrity of the electrical components 3.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a history of producing reliable automotive components, Cummins has built a reputation for excellence. The company’s focus on advancing technology and maintaining high standards in manufacturing is reflected in its wide range of products, including the 3630777 Wiring Retainer Bracket.

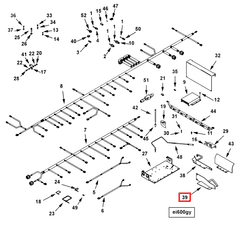

Engine Compatibility with Wiring Retainer Bracket Part 3630777

The Wiring Retainer Bracket part number 3630777, manufactured by Cummins, is designed to fit seamlessly with specific engine models. This bracket plays a role in securing and organizing the wiring harness, ensuring that electrical connections remain stable and protected throughout the engine’s operation.

K38 Engine

For the K38 engine, the Wiring Retainer Bracket 3630777 is engineered to align perfectly with the engine’s design. It provides a robust mounting point for the wiring harness, preventing any undue stress or movement that could lead to electrical faults or damage. The bracket’s precise fit ensures that it complements the engine’s layout, maintaining the integrity of the electrical system.

K50 Engine

Similarly, the K50 engine benefits from the use of the Wiring Retainer Bracket 3630777. This bracket is specifically tailored to fit the K50’s configuration, offering a secure and reliable method for managing the wiring harness. By providing a stable platform for the harness, the bracket helps to maintain the electrical system’s efficiency and reliability, contributing to the overall performance of the engine.

Grouping of Engines

Both the K38 and K50 engines share a commonality in their requirement for the Wiring Retainer Bracket 3630777. This part plays a role in these engines, as it ensures that the wiring harness is properly managed and secured. The bracket’s design is such that it can be adapted to fit both engine models, highlighting its versatility and importance in maintaining the electrical integrity of these engines.

Role of Part 3630777 Wiring Retainer Bracket in Engine Systems

The 3630777 Wiring Retainer Bracket is a component in the orchestration of various engine systems, ensuring both functionality and safety. This bracket is specifically designed to secure and organize wiring harnesses within the engine compartment, facilitating a streamlined and protected pathway for electrical signals.

Integration with Engine Monitor

When integrated with an engine monitor, the 3630777 Wiring Retainer Bracket plays a role in maintaining the integrity of the wiring that connects various sensors and control units. By securing the wiring, it prevents potential damage from vibrations or abrasion, ensuring consistent and reliable data transmission to the engine monitor. This, in turn, allows for accurate monitoring of engine parameters such as temperature, pressure, and fuel efficiency.

Coordination with Electronic Engine Components

In electronic engine systems, the 3630777 Wiring Retainer Bracket ensures that the wiring associated with electronic control units (ECUs) and other electronic components remains organized and protected. This is particularly important in modern engines where electronic systems play a pivotal role in performance optimization and emissions control. The bracket helps in reducing electromagnetic interference (EMI) by keeping wires away from high-voltage components and metal surfaces.

Support for Bracket Wiring Mounting

The 3630777 Wiring Retainer Bracket is often used in conjunction with other bracket wiring mounting solutions to create a comprehensive wiring management system. It supports the mounting of additional brackets and components, providing a stable and secure foundation for complex wiring configurations. This is especially beneficial in high-performance engines where space is at a premium, and efficient wiring management is paramount.

Enhancing Safety and Performance

By securing wiring in a designated area, the 3630777 Wiring Retainer Bracket contributes to the overall safety and performance of the engine. It reduces the risk of short circuits and electrical fires by keeping wires away from moving parts and heat sources. Additionally, it aids in maintaining a clean and organized engine bay, which is not only aesthetically pleasing but also makes troubleshooting and maintenance more straightforward.

Conclusion

In summary, the 3630777 Wiring Retainer Bracket is a component in the engine’s electrical system, ensuring the safe and efficient transmission of electrical signals while protecting the wiring from potential damage. Its role in supporting and organizing wiring is indispensable in modern engine systems, where electronic components and monitoring systems are increasingly prevalent.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.