3630407

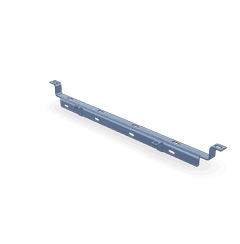

Wiring Retainer Bracket

Cummins®

AVAILABLE

9 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3630407 Wiring Retainer Bracket, manufactured by Cummins, is a component designed to enhance the electrical system of commercial trucks. This bracket is part of a broader effort to manage and secure wiring harnesses within the vehicle. Effective wiring management is vital for the reliable operation of a truck’s electrical system, contributing to both safety and performance 1.

Basic Concepts of Wiring Retainer Brackets

A Wiring Retainer Bracket is a device used to organize and secure wiring harnesses within a vehicle. It plays a role in maintaining the integrity of the electrical system by keeping wires in place, protecting them from physical damage, and ensuring they do not interfere with other components. This contributes to the overall operation and safety of the vehicle by maintaining a tidy and secure wiring environment 2.

Purpose of the 3630407 Wiring Retainer Bracket

The 3630407 Wiring Retainer Bracket is specifically designed to aid in the organization and securing of wiring harnesses in trucks. By holding wires in place, it helps prevent damage that could occur from movement or contact with other parts. This ensures efficient electrical performance and reduces the risk of faults that could arise from unsecured or damaged wiring 3.

Key Features

The 3630407 Wiring Retainer Bracket features a robust material composition, typically including durable plastics or metals, which provide resistance to wear and environmental factors. Its design elements may include clips, slots, or other mechanisms to securely hold wires in place. Unique attributes such as corrosion resistance and flexibility in mounting options enhance its functionality and durability, making it suitable for the demanding conditions encountered in commercial trucking.

Benefits of Using the 3630407 Wiring Retainer Bracket

Incorporating the 3630407 Wiring Retainer Bracket into truck wiring systems offers several advantages. It improves wire management by keeping harnesses organized and secured, which can lead to a reduction in the risk of electrical faults. The bracket’s durable construction ensures it can withstand harsh conditions, contributing to the longevity and reliability of the truck’s electrical system.

Installation Considerations

When installing the 3630407 Wiring Retainer Bracket, it is important to consider proper placement to ensure it effectively secures the wiring harnesses without interfering with other components. Securing methods should follow manufacturer guidelines to ensure stability and durability. Compatibility with other components should also be verified to ensure a seamless integration into the truck’s electrical system.

Troubleshooting and Maintenance

Common issues with Wiring Retainer Brackets may include loosening over time or damage from environmental factors. Troubleshooting steps may involve checking for secure attachment, inspecting for signs of wear or corrosion, and replacing any damaged components. Regular maintenance, such as inspecting the bracket and ensuring wires are properly secured, can help ensure the longevity and effectiveness of the bracket.

Cummins: Manufacturer Overview

Cummins is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industries. Known for their commitment to quality and innovation, Cummins has a history of producing reliable and high-performance components. Their products, including the 3630407 Wiring Retainer Bracket, reflect their dedication to enhancing the efficiency and safety of commercial vehicles.

Cummins Wiring Retainer Bracket 3630407 Compatibility

The Cummins Wiring Retainer Bracket part number 3630407 is designed to fit seamlessly with a variety of Cummins engines, ensuring that electrical wiring is securely managed and protected. This bracket is essential for maintaining the integrity of the engine’s electrical system by preventing wires from becoming dislodged or damaged.

K38 Engine Series

The K38 engine series, known for its robust performance and reliability, integrates the Wiring Retainer Bracket 3630407 effectively. This bracket is specifically engineered to align with the K38’s design, ensuring that the wiring harness is held firmly in place. This is particularly important in environments where the engine may be subjected to vibrations and harsh conditions, as it helps to maintain the stability and functionality of the electrical system.

Grouping of Compatible Engines

The Wiring Retainer Bracket 3630407 is not limited to the K38 series alone. It is also compatible with other Cummins engines that share similar design characteristics and mounting points. This includes:

- K19 Series: The K19 engines benefit from the bracket’s ability to secure wiring in a manner that prevents interference with other engine components.

- QSB Series: For the QSB engines, the bracket ensures that the wiring harness remains intact, reducing the risk of electrical faults due to movement or stress.

- QSC Series: The QSC engines also utilize this bracket to maintain the integrity of their electrical systems, ensuring that all connections remain secure and reliable.

By providing a secure mounting point for the wiring harness, the Wiring Retainer Bracket 3630407 plays a role in the overall performance and longevity of these engines. Its design ensures that the electrical system operates smoothly, without the risk of damage from loose or frayed wires.

Role of Part 3630407 Wiring Retainer Bracket in Engine Systems

The 3630407 Wiring Retainer Bracket is a component in the assembly and maintenance of various engine systems. It is primarily used to secure and organize wiring harnesses, ensuring they remain in place and are protected from potential damage during engine operation.

Integration with Engine Components

-

Wiring Harness: The primary function of the 3630407 Wiring Retainer Bracket is to hold the wiring harness in a fixed position. This prevents the wires from moving excessively, which could lead to wear, fraying, or disconnection. Proper retention of the wiring harness is vital for consistent electrical performance and safety.

-

Electronic Engine Systems: In electronic engine systems, the Wiring Retainer Bracket ensures that all electronic connections remain secure. This is particularly important for sensors, actuators, and other electronic components that require stable and reliable connections to function correctly.

-

Engine Monitor: When integrated with an engine monitor system, the Wiring Retainer Bracket helps maintain the integrity of the monitoring circuits. This ensures accurate data collection and transmission, which is essential for diagnostics and performance tuning.

-

Mounting Systems: The bracket is often used in conjunction with mounting systems to secure the wiring harness to the engine frame or other structural components. This not only organizes the wiring but also protects it from vibrations and mechanical stress.

-

Sensor Upfit: For sensor upfit applications, the Wiring Retainer Bracket plays a role in keeping sensor wiring neatly arranged. This is important for both the installation process and the ongoing operation of the sensors.

-

Kit Applications: In various kit applications, the Wiring Retainer Bracket is included to simplify the installation process. It ensures that all wiring is correctly positioned and secured, reducing the risk of installation errors.

By effectively securing and organizing the wiring, the 3630407 Wiring Retainer Bracket contributes to the overall reliability and performance of engine systems. Its role in maintaining the structural integrity of wiring harnesses is fundamental to the proper functioning of modern engine components.

Conclusion

The 3630407 Wiring Retainer Bracket by Cummins is a critical component for the effective management and protection of wiring harnesses in commercial trucks. Its robust design, compatibility with various Cummins engines, and role in enhancing the reliability and performance of engine systems make it an invaluable part of modern vehicle electrical systems.

-

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Drozdziel, Pawel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.