This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

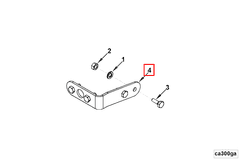

The Cummins 3625792 Instrument Bracket is a component designed for use in commercial trucks. It serves a specific role within the vehicle’s instrument panel, contributing to the overall functionality and organization of the dashboard. This part is integral to the secure placement and protection of various gauges and indicators, ensuring they are correctly positioned and safeguarded against potential damage.

Purpose and Functionality

The primary purpose of this Cummins part is to support and secure gauges and indicators within a truck’s instrument panel. By providing a stable mounting point, it ensures that these critical components remain in place and are easily accessible to the driver. This bracket plays a role in maintaining the organization of the instrument panel, allowing for clear and unobstructed visibility of all gauges and indicators 1.

Key Features

The Cummins 3625792 is characterized by several key features that enhance its performance and durability. Its design is tailored to fit seamlessly within the instrument panel, ensuring a snug and secure fit. The bracket is constructed from high-quality materials, which contribute to its robustness and longevity. Additionally, it may include unique attributes such as corrosion-resistant coatings or vibration-dampening properties, further enhancing its functionality in the demanding environment of a commercial truck 2.

Installation Process

Installing this part involves several steps to ensure proper setup. Begin by identifying the correct location within the instrument panel for the bracket. Carefully align the bracket with the mounting points, ensuring it is level and securely fastened. It is important to follow the manufacturer’s instructions closely, paying attention to any specific torque specifications for tightening screws or bolts. Once installed, verify that the bracket is stable and that all gauges and indicators are properly positioned and secured.

Benefits

Utilizing the Cummins 3625792 offers several advantages. It contributes to improved organization within the instrument panel, making it easier for the driver to monitor all gauges and indicators. The bracket’s durable construction ensures long-lasting performance, even under the rigors of commercial truck operation. Additionally, its design facilitates ease of access for maintenance and repairs, allowing for quick and efficient servicing of the instrument panel components 3.

Common Issues and Troubleshooting

While this Cummins part is designed for reliability, certain issues may arise over time. Common problems include loosening of the bracket, which can affect the stability of gauges and indicators. To address this, regularly check the tightness of all mounting screws and bolts, re-securing them as necessary. Additionally, inspect the bracket for signs of wear or damage, replacing it if any deterioration is observed to maintain the integrity of the instrument panel.

Maintenance Tips

To keep this part in optimal condition, regular maintenance is recommended. This includes periodic inspections to ensure the bracket remains securely fastened and free from damage. Cleaning the bracket and surrounding area can prevent the accumulation of dirt and debris, which may affect its performance. Adhering to recommended maintenance intervals for the instrument panel as a whole will also contribute to the longevity and reliability of the bracket.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its commitment to producing high-quality components for commercial vehicles. With a rich history and a strong reputation, Cummins has consistently delivered reliable and durable parts that meet the demanding needs of the commercial trucking sector. The company’s dedication to innovation and quality is evident in its wide range of products, including the Cummins 3625792.

Compatibility

The Cummins Instrument Bracket part number 3625792 is designed to fit seamlessly with a variety of Cummins engines, ensuring precise and reliable mounting of gauges and other instruments. This bracket is engineered to provide a sturdy and secure attachment point, which is crucial for maintaining the integrity of the engine’s instrumentation system.

V903 Engine Group

For the V903 engine series, the Instrument Bracket 3625792 is specifically tailored to fit the unique design and layout of these engines. The bracket’s design accommodates the placement of various gauges and sensors, ensuring that they are positioned correctly for optimal performance and ease of access during maintenance. The precision engineering of this bracket ensures that it integrates smoothly with the engine’s architecture, providing a reliable mounting solution that can withstand the rigors of engine operation.

Role of Part 3625792 in Engine Systems

The Part 3625792 is an essential component that facilitates the integration and secure positioning of various instruments within engine systems. Its primary function is to provide a stable and reliable mounting solution for the Air Restriction Indicator and other associated indicators.

Integration with Air Restriction Indicator Mounting

When installed, the Instrument Bracket ensures that the Air Restriction Indicator is correctly positioned. This indicator is vital for monitoring the air flow within the engine system, providing real-time data on any restrictions that may affect performance. The bracket’s design allows for easy access and adjustment, ensuring that the indicator remains aligned and functional under varying operational conditions.

Supporting Indicator Functionality

The bracket plays a significant role in supporting the overall functionality of the indicator. By securely holding the indicator in place, it prevents any movement or misalignment that could lead to inaccurate readings. This stability is essential for maintaining the precision of the data collected, which is used for diagnostic and maintenance purposes.

Enhancing Air Restriction Monitoring

In conjunction with the Air Restriction monitoring system, the Instrument Bracket helps in creating a cohesive setup. The bracket ensures that the indicator is optimally placed to detect any changes in air flow efficiently. This setup is particularly important in high-performance engines where air flow management directly impacts engine efficiency and power output.

Facilitating Maintenance and Adjustments

The design of the Instrument Bracket also considers the needs of maintenance personnel. It allows for straightforward installation and removal, which is beneficial during routine checks or when adjustments are necessary. This ease of access ensures that maintenance tasks can be performed quickly and with minimal disruption to the engine system.

Conclusion

In summary, the Part 3625792 is a key component that enhances the functionality and reliability of engine systems by providing a secure and stable mounting solution for critical indicators. Its design and features contribute to the overall efficiency and maintenance of the engine’s instrumentation system, ensuring that all gauges and indicators are accurately positioned and easily accessible for monitoring and servicing.

-

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Khajepour, Amir. Synthesis Lectures on Advances in Automotive Technology. Springer, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.