This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

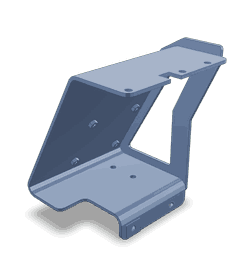

The Cummins 3607849 Breather Tube is a component designed for use in heavy-duty trucks. Its purpose is to facilitate the proper ventilation of the engine system, ensuring that pressure levels remain within optimal ranges. This component plays a significant role in maintaining the overall health and efficiency of the truck’s engine.

Basic Concepts of Breather Tubes

A breather tube is a component found in many engine systems, including those of heavy-duty trucks. Its primary function is to allow air to enter and exit the engine crankcase, which helps to regulate pressure and prevent the buildup of harmful gases. By maintaining a balanced pressure environment, the breather tube contributes to the engine’s longevity and performance 1.

Purpose of the Cummins 3607849 Breather Tube

This Cummins part is specifically designed to play a role in the truck’s engine system by regulating pressure and providing ventilation. It allows for the escape of excess pressure and contaminants from the crankcase, which helps to maintain a clean and efficient engine environment. This, in turn, supports the engine’s overall performance and durability 2.

Key Features

The Cummins 3607849 Breather Tube is constructed from durable materials that are resistant to the harsh conditions found within a truck’s engine compartment. Its design includes features that enhance its performance, such as a filtration system that captures contaminants before they can enter the engine. Additionally, the tube is engineered to withstand high temperatures and pressures, ensuring reliable operation under demanding conditions 3.

Benefits

The use of the Cummins 3607849 Breather Tube offers several benefits to the engine system. By maintaining optimal pressure levels and providing effective ventilation, it contributes to improved engine performance. Furthermore, the tube’s durable construction and efficient design help to extend the engine’s longevity and enhance its reliability, making it a valuable component for heavy-duty truck applications 4.

Installation Process

To install the Cummins 3607849 Breather Tube, begin by locating the appropriate connection point on the engine. Using the necessary tools, carefully remove the old breather tube and clean the connection area. Next, position the new breather tube and secure it in place, ensuring a tight and leak-free connection. Finally, perform a pressure test to confirm that the installation is successful and that the breather tube is functioning as intended.

Troubleshooting Common Issues

Common problems associated with breather tubes may include leaks, blockages, or contamination. To address these issues, first, inspect the breather tube for any visible damage or obstructions. If a leak is detected, ensure that all connections are secure and free from debris. In the case of blockages or contamination, clean the breather tube and its associated components, or replace the tube if necessary.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 3607849 Breather Tube, regular maintenance is recommended. This includes periodic inspection for signs of wear, damage, or contamination. Additionally, cleaning the breather tube and its associated components can help to prevent blockages and maintain efficient operation. By following these maintenance tips, truck owners can help to ensure the continued reliability of their engine system.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to providing high-quality, innovative solutions for a wide range of industries, including automotive, construction, and agriculture. The company’s extensive product range and dedication to excellence have established Cummins as a trusted name in the industry.

Cummins Breather Tube Part 3607849 in Engine Applications

The Cummins Breather Tube part number 3607849 is a component in the engine systems of various Cummins engines, ensuring proper ventilation and pressure management within the engine’s crankcase. This part is designed to allow air to escape from the crankcase while preventing contaminants from entering, thus maintaining the engine’s operational integrity.

QSK19G Engine

In the QSK19G engine, the breather tube part 3607849 plays a role in the engine’s ventilation system. This engine, known for its robust performance and reliability, benefits from the breather tube’s ability to manage pressure fluctuations within the crankcase. By facilitating the escape of gases and preventing the ingress of contaminants, the breather tube helps maintain optimal engine performance and longevity.

The breather tube is strategically positioned within the engine’s architecture to ensure efficient air flow and pressure regulation. Its design and placement are critical to the engine’s overall health, as it helps prevent issues such as oil foaming and contamination, which can lead to engine damage if not properly managed.

The integration of the breather tube part 3607849 in the QSK19G engine is a testament to Cummins’ commitment to quality and reliability. This part, along with other components, ensures that the engine operates smoothly and efficiently, providing the power and durability that users expect from Cummins engines.

Role of Part 3607849 Breather Tube in Engine Systems

The part 3607849 Breather Tube is a component in maintaining the efficiency and reliability of various engine systems. It is specifically designed to manage the ventilation of crankcase gases, which are byproducts of the combustion process.

In the context of the Fuel Control Module, the breather tube ensures that the crankcase pressure remains within optimal levels. This is important because excessive pressure can lead to leaks or damage to the module, affecting fuel delivery and overall engine performance.

When integrated with the Module, the breather tube helps in maintaining a stable environment for sensitive electronic components. By allowing gases to escape, it prevents the buildup of pressure that could otherwise interfere with the module’s operation.

For the Fuel Control system, the breather tube plays a role in ensuring that the fuel mixture remains consistent. By regulating crankcase pressure, it indirectly supports the fuel control system in delivering the correct air-fuel ratio, which is vital for combustion efficiency and emissions control.

In summary, the part 3607849 Breather Tube is a key component in preserving the integrity and performance of engine systems by effectively managing crankcase ventilation.

Conclusion

The Cummins 3607849 Breather Tube is a vital component in the engine systems of heavy-duty trucks, ensuring proper ventilation and pressure management within the engine’s crankcase. Its durable construction, efficient design, and role in maintaining optimal engine performance make it a valuable asset for truck owners and operators. Regular maintenance and proper installation are essential to ensure the continued reliability and efficiency of this critical component.

-

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.