This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5296739 Tube Brace, a component designed by Cummins, is integral to the structural framework of heavy-duty trucks. This Cummins part contributes to the operational efficiency and overall integrity of the vehicle, reflecting Cummins’ commitment to robust and reliable products for heavy-duty applications 1.

Basic Concepts of Tube Braces

Tube braces are essential in vehicle construction for enhancing chassis rigidity and stability. They connect various frame parts, distributing loads evenly and reducing stress on individual components, which is vital for the vehicle’s integrity under heavy-duty use 2.

Purpose of the 5296739 Tube Brace

The 5296739 Tube Brace reinforces the truck frame in high-stress areas, providing additional strength and stability. This reinforcement is key to maintaining frame rigidity under load, crucial for alignment and performance in heavy-duty applications 3.

Key Features

This part is constructed from high-strength materials, ensuring durability and resistance to wear. Its design is engineered for a precise fit within the truck’s frame, with features like corrosion-resistant coatings and specific geometries to optimize performance in demanding conditions 4.

Benefits

Utilizing the 5296739 Tube Brace enhances structural rigidity, contributing to the truck’s durability and safety. It supports better alignment and stability of components, leading to improved performance and longevity 5.

Installation Considerations

Proper installation of the 5296739 Tube Brace is essential for its effectiveness. Following manufacturer guidelines, including specific prerequisites and the use of special tools, ensures correct alignment and secure fastening, maximizing its contribution to the truck’s structural integrity 6.

Troubleshooting and Maintenance

Common issues with tube braces include corrosion, misalignment, or impact damage. Regular inspection and maintenance, such as keeping the brace clean, checking for corrosion, and ensuring tight fasteners, are crucial for maintaining its longevity and effectiveness 7.

Cummins: Manufacturer Overview

Cummins is renowned in the heavy-duty truck industry for its reliable and high-quality components. Their commitment to innovation, quality, and customer satisfaction is evident in their wide range of products designed for heavy-duty applications 8.

Tube Brace Part 5296739 in Cummins Engines

The 5296739 Tube Brace is a critical component in several Cummins engine models, essential for maintaining structural integrity and operational efficiency.

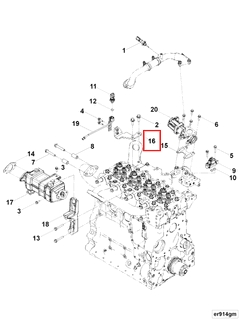

Application in QSB4.5 CM2250 EC Engines

In the QSB4.5 CM2250 EC engine, the 5296739 Tube Brace secures engine components, ensuring proper alignment and support, which is vital for engine performance and longevity.

Compatibility with Cummins Engines

This part is compatible with various Cummins engines, including QSB4.5 CM2250 EC, QSB6.7, and QSC6.7, due to their similar design principles and structural requirements.

Importance of the Tube Brace

The 5296739 Tube Brace is designed to withstand engine operation rigors, providing necessary support to engine tubes and preventing misalignment and damage. It is crucial for maintaining engine stability and efficiency.

Role of Part 5296739 Tube Brace in Engine Systems

The 5296739 Tube Brace enhances the structural integrity and operational efficiency of engine systems. In recirculation systems, it ensures smooth and secure gas direction, minimizing leak risks and ensuring consistent recirculation performance. In exhaust systems, it supports exhaust pipes and manifolds, maintaining alignment and stability under high temperatures and vibrations, preventing leaks, and contributing to the exhaust system’s durability.

Conclusion

The 5296739 Tube Brace is a vital component in heavy-duty truck and engine systems, offering enhanced structural integrity, improved performance, and increased safety. Its proper installation and maintenance are crucial for maximizing its benefits and ensuring the longevity and reliability of the vehicle and engine systems.

-

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

Frank Sander, Diesel Mechanics, First Edition, Global Media, 2007.

↩ -

R Mananathan, Automobile Wheel Alignment and Wheel Balancing, SAE International, 2022.

↩ -

Konrad Reif Ed, Diesel Engine Management Systems and Components, Springer Vieweg, 2014.

↩ -

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

Frank Sander, Diesel Mechanics, First Edition, Global Media, 2007.

↩ -

R Mananathan, Automobile Wheel Alignment and Wheel Balancing, SAE International, 2022.

↩ -

Konrad Reif Ed, Diesel Engine Management Systems and Components, Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.