This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

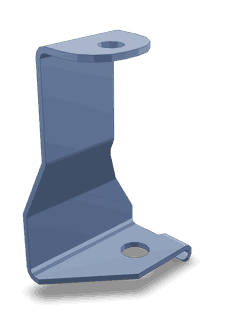

The Cummins 4933023 Wiring Brace is a component designed to enhance the electrical system of heavy-duty trucks. Its purpose is to support and organize wiring harnesses, ensuring they remain secure and undamaged during operation. This part plays a role in the engine cooling system by maintaining the integrity and efficiency of the truck’s electrical system 1.

Purpose and Function

The Cummins 4933023 Wiring Brace serves to hold and organize the wiring harnesses within a heavy-duty truck. By securing the wires in place, it helps prevent them from moving excessively or coming into contact with other components, which could lead to wear, damage, or electrical faults. This organization ensures that the electrical system operates efficiently and reliably, reducing the likelihood of issues that could arise from poorly managed wiring 2.

Key Features

The design of the Cummins 4933023 Wiring Brace incorporates several features that enhance its functionality. It is constructed from durable materials to withstand the harsh conditions often encountered in heavy-duty truck environments. The brace offers various mounting options, allowing it to be securely attached in different configurations to accommodate the specific needs of the truck’s electrical system. Additionally, its design includes elements that facilitate easy access to the wiring for maintenance or repairs 3.

Benefits

Installing the Cummins 4933023 Wiring Brace provides several advantages. It improves wire management by keeping the harnesses organized and secure, which can lead to a reduction in electrical faults. The brace also enhances the durability of the wiring system by protecting the wires from physical damage. Furthermore, by maintaining the integrity of the electrical connections, it contributes to the overall reliability and performance of the truck 4.

Installation Process

Proper installation of the Cummins 4933023 Wiring Brace involves several steps. First, identify the appropriate location for the brace within the truck’s electrical system. Then, using the provided mounting hardware, secure the brace in place. Ensure that the wiring harnesses are properly routed through the brace and that all connections are tight and secure. It is recommended to use the appropriate tools for installation to ensure a secure fit and to avoid damaging the wiring or the brace 5.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the Cummins 4933023 Wiring Brace, regular maintenance is advised. Inspect the brace and the wiring harnesses periodically for signs of wear, damage, or loose connections. Addressing any issues promptly can prevent more significant problems from developing. Common issues may include loose mounting, damaged wiring, or corrosion. Troubleshooting steps should involve securing any loose components, repairing or replacing damaged wiring, and cleaning or treating any corrosion to maintain the electrical system’s integrity 6.

Compatibility and Usage

The Cummins 4933023 Wiring Brace is designed for use in specific types of trucks and engine models. Its application is intended for environments where heavy-duty performance and reliability are paramount. The brace is engineered to withstand various driving conditions and environments, ensuring that the electrical system remains functional and efficient under demanding circumstances 7.

Safety Considerations

When handling and installing the Cummins 4933023 Wiring Brace, it is important to follow safety guidelines to avoid electrical hazards and ensure personal safety. Always disconnect the battery before beginning any work on the electrical system to prevent the risk of electric shock. Use insulated tools and wear appropriate personal protective equipment (PPE) to protect against potential hazards. Additionally, ensure that all wiring and connections are secure and properly insulated after installation to prevent short circuits or other electrical issues 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a key player in the automotive industry, particularly in the production of diesel engines and components that enhance the performance, efficiency, and reliability of vehicles. The company’s commitment to innovation and quality is reflected in its extensive product line, which includes parts like the Cummins 4933023 Wiring Brace, designed to meet the demanding requirements of heavy-duty applications 9.

Compatibility of Cummins Wiring Brace 4933023

The Cummins Wiring Brace part number 4933023 is designed to fit a variety of Cummins engines, ensuring secure and organized wiring management. Below is a detailed breakdown of the engines with which this part is compatible:

ISB/ISD 6.7L Engines

- ISB/ISD 6.7 CM2150 SN

- ISBE CM2150

These engines, part of the ISB/ISD 6.7L family, benefit from the Wiring Brace 4933023 by providing a stable mounting point for wiring harnesses, which helps in maintaining the integrity of electrical connections and preventing wear and tear.

ISB 5.9L Engine

- ISB 5.9 CM2880 B140

The ISB 5.9L engine also utilizes the Wiring Brace 4933023 to manage its wiring effectively. This part is crucial in ensuring that the wiring remains secure and organized, which is essential for the engine’s reliable operation.

ISBE 4.5L Engines

- ISBE4 CM850

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

The ISBE4 and QSB4.5 engines, both 4.5L variants, are compatible with the Wiring Brace 4933023. This part aids in keeping the wiring tidy and secure, which is vital for the smooth functioning of these engines.

QSB 6.7L Engines

- QSB6.7 CM2250

- QSB6.7 CM850 (CM2850)

The QSB 6.7L engines also incorporate the Wiring Brace 4933023. This part ensures that the wiring is properly managed, reducing the risk of damage and enhancing the overall reliability of the engine.

QSB 7.0L Engine

- QSB7 CM2880 B117

The QSB 7.0L engine is another beneficiary of the Wiring Brace 4933023. This part provides a robust solution for wiring management, ensuring that the wiring remains intact and functional throughout the engine’s operation.

By using the Wiring Brace 4933023, these Cummins engines can maintain organized and secure wiring, which is essential for their performance and longevity.

Role of Part 4933023 Wiring Brace in Engine Systems

The 4933023 Wiring Brace is an integral component in the assembly and maintenance of various wiring systems within engine setups. Its primary function is to provide structural support and organization to the intricate network of wires and harnesses that are essential for the operation of modern engines.

Integration with Electronic Control Module (ECM) Wiring Harness

In systems utilizing an Electronic Control Module (ECM) Wiring Harness, the 4933023 Wiring Brace plays a significant role. It ensures that the wiring harness is securely positioned and protected from potential damage due to vibrations or contact with other engine components. This support is vital for maintaining the integrity of the signals transmitted between the ECM and various engine sensors and actuators 10.

Support for Engine Control Wiring

When it comes to Engine Control Wiring, the 4933023 Wiring Brace helps in managing the complex web of wires that control fuel injection, ignition timing, and other critical engine functions. By keeping these wires organized and secured, it prevents issues such as short circuits or signal interference, which could lead to engine malfunctions 11.

Enhancing Harness Durability

In applications where a Harness is used to connect different parts of the engine’s electrical system, the 4933023 Wiring Brace contributes to the durability and longevity of the harness. It reduces the strain on the wires caused by engine movement and heat, thereby extending the operational life of the harness 12.

Facilitating Maintenance and Repairs

The presence of the 4933023 Wiring Brace in an engine’s wiring system also aids in maintenance and repair processes. By keeping the wiring organized and accessible, it allows mechanics to more easily diagnose and address electrical issues, reducing downtime and facilitating quicker repairs 13.

Conclusion

In summary, the 4933023 Wiring Brace is a key component in ensuring the efficient and reliable operation of an engine’s electrical system. Its role in supporting and organizing wiring harnesses and engine control wiring is essential for the overall performance and durability of the engine.

-

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5613076.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5613076.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5613076.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5613076.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5613076.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5613076.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.