This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Tube Brace 4924558, manufactured by Cummins, is a component designed for commercial truck applications. Cummins, a well-established name in the industry, produces a range of parts aimed at enhancing the performance and durability of trucks. This Cummins part is significant in this context as it contributes to the structural integrity and operational efficiency of commercial trucks.

Basic Concepts of Tube Braces

A tube brace is a structural component used in vehicle frameworks to reinforce and stabilize the chassis. Its general function is to distribute loads more evenly across the vehicle’s frame, thereby enhancing the overall integrity and performance. By providing additional support, tube braces help in maintaining the structural alignment and strength of the truck, which is crucial under various driving conditions and loads 1.

Purpose of the 4924558 Tube Brace

This part plays a specific role in the operation and structural integrity of a truck. It supports other components by reinforcing the chassis, which helps in maintaining the truck’s alignment and stability. This reinforcement contributes to the truck’s durability by reducing stress on critical points of the frame, thereby enhancing its performance and longevity 2.

Key Features

The 4924558 Tube Brace is characterized by several key features that enhance its functionality and durability. It is typically made from high-strength steel, which provides excellent resistance to wear and deformation. The design of the brace includes precise dimensions and weld points to ensure a secure fit and optimal performance. Additionally, the brace may feature protective coatings to resist corrosion, further extending its service life.

Benefits of Using the 4924558 Tube Brace

Incorporating this part into truck designs offers several advantages. It improves structural stability by reinforcing the chassis, which can lead to enhanced load-bearing capacity. This added strength allows the truck to handle heavier loads more effectively. Furthermore, the brace contributes to the operational lifespan of the truck by reducing the risk of frame damage and misalignment.

Installation Considerations

When installing the 4924558 Tube Brace, it is important to follow guidelines and best practices to ensure optimal performance. Preparatory steps include cleaning the installation area and ensuring that the chassis is free from any existing damage. The tools required may include a welding torch, alignment tools, and fasteners. Proper alignment is crucial to ensure that the brace effectively reinforces the chassis without causing undue stress on other components.

Troubleshooting Common Issues

Common problems associated with tube braces include corrosion, fatigue, and misalignment. Corrosion can be addressed by applying protective coatings or replacing the affected section. Fatigue, which may result from repeated stress, can be mitigated by regular inspections and timely replacement of worn components. Misalignment issues should be corrected by realigning the brace or addressing any underlying chassis issues.

Maintenance Tips

Regular maintenance of the 4924558 Tube Brace is important to ensure its continued effectiveness. Inspection routines should include checking for signs of corrosion, wear, or damage. Cleaning procedures may involve removing dirt and debris to prevent buildup that could lead to corrosion. Replacement or repair should be considered if significant wear or damage is detected during inspections.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. The company has a long history of producing reliable and high-performance truck components. Cummins’ product range includes engines, transmissions, and various aftermarket parts, all designed to enhance the efficiency and durability of commercial vehicles. The reputation of Cummins is built on its dedication to excellence in manufacturing and its continuous efforts to improve truck component technology 3.

Tube Brace Part 4924558 in Cummins Engines

The Tube Brace part 4924558, manufactured by Cummins, is a critical component in several of their engine models. This part is designed to provide structural support and stability to the engine’s internal components, ensuring optimal performance and longevity.

QSK60 and CM850 Engines

In the QSK60 and CM850 engines, the Tube Brace part 4924558 plays a pivotal role in maintaining the integrity of the engine’s framework. These engines are known for their robust design and high power output, and the Tube Brace is integral in supporting the engine’s internal tubes and components. By providing a stable mounting point, it helps to reduce vibrations and wear, contributing to the overall reliability of these engines.

MCRS Engines

The MCRS engines also benefit from the Tube Brace part 4924558. This part is essential in ensuring that the engine’s components remain securely in place, even under high-stress conditions. The Tube Brace helps to distribute loads evenly, preventing deformation and potential failure of critical engine parts. Its placement and design are crucial for maintaining the alignment and performance of the engine.

Grouping of Engines

The Tube Brace part 4924558 is a common component across the QSK60, CM850, and MCRS engines, highlighting its importance in Cummins’ engine lineup. By using this part in multiple engine models, Cummins ensures consistency in quality and performance, providing engine users with a reliable and durable component that enhances the overall functionality of their engines.

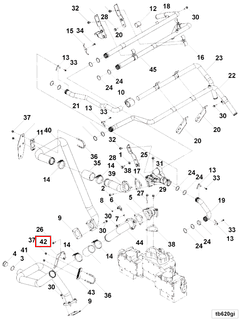

Role of Part 4924558 Tube Brace in Auxiliary Cooling Systems

The 4924558 Tube Brace is an essential component in the assembly and functionality of auxiliary cooling systems. Its primary role is to provide structural support and stability to the various tubes and hoses that are integral to the system’s operation.

In the context of an auxiliary cooling system, the Tube Brace ensures that the coolant tubes remain securely in place, minimizing the risk of vibrations or movement that could lead to leaks or failures. This is particularly important in high-stress environments where the engine and its components are subject to significant mechanical forces.

Additionally, the Tube Brace helps maintain the optimal alignment of the tubes, which is vital for efficient coolant flow. Proper alignment ensures that the coolant can circulate effectively through the system, enhancing the overall cooling performance and reliability of the engine.

Furthermore, the Tube Brace contributes to the durability of the auxiliary cooling system by protecting the tubes from external impacts and wear. This protective function is essential for prolonging the lifespan of the cooling system components and ensuring consistent performance over time.

Conclusion

In summary, the 4924558 Tube Brace plays a significant role in supporting, aligning, and protecting the tubes within the auxiliary cooling system, thereby contributing to the system’s efficiency and reliability. Its integration into various Cummins engine models underscores its importance in maintaining the structural integrity and performance of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.