This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

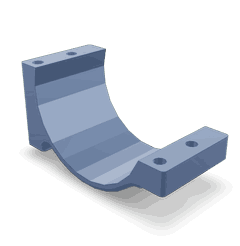

The Cummins 4012069 Starting Motor Brace is a component designed to enhance the functionality of the starting system in commercial trucks. Its role is to provide additional support to the starting motor, ensuring reliable engine starts under various operating conditions. This brace is integral to maintaining the efficiency and reliability of the truck’s starting mechanism 1.

Purpose and Function

The Starting Motor Brace plays a role in the truck’s starting system by offering structural support to the starting motor. This support helps in stabilizing the motor during the starting process, which can be particularly demanding on the motor and its mounting points. By reducing the stress on the motor and its connections, the brace contributes to consistent and reliable engine starts, which is vital for the operational readiness of commercial trucks 2.

Key Features

The Cummins 4012069 Starting Motor Brace is engineered with high-quality materials to ensure durability and performance. Its design includes robust mounting points that secure it firmly in place, minimizing any movement that could affect the starting motor’s operation. The brace is constructed to withstand the rigors of commercial truck environments, featuring a design that enhances its performance and longevity 3.

Benefits

The advantages of the Cummins 4012069 Starting Motor Brace include improved durability of the starting system components, enhanced reliability in engine starts, and a potential reduction in wear on the starting motor. These benefits contribute to the overall efficiency and longevity of the truck’s engine starting mechanism.

Installation and Compatibility

Proper installation of the Starting Motor Brace is crucial for its effective function. It is designed to be compatible with specific Cummins engines, ensuring a seamless integration into the existing starting system. Installation guidelines should be followed to ensure that the brace is securely mounted and properly aligned with the starting motor.

Maintenance and Troubleshooting

Routine maintenance of the Starting Motor Brace involves checking for any signs of wear or damage and ensuring that all mounting points are secure. Common issues may include loosening of the brace or damage from environmental factors. Regular inspections can help identify these issues early, allowing for timely repairs or replacements to maintain the performance of the starting system.

Performance Impact

The Starting Motor Brace influences the overall performance and reliability of the truck’s starting system by providing additional support to the starting motor. This support can lead to more consistent engine starts and reduced stress on the motor, potentially extending its operational life. Performance data and user testimonials may provide further insight into the brace’s effectiveness in real-world applications.

Compatibility with Cummins Engines

This part is designed to be compatible with several Cummins engine models, including the QSV91-G4 CM558/CM700 V102 and QSV91G engines. The Starting Motor Brace is engineered to fit seamlessly into the engine’s architecture, providing the necessary support to withstand the forces exerted during the starting process, thereby enhancing the longevity and performance of the starting motor.

Role in Engine Systems

The 4012069 Starting Motor Brace is an integral component in the assembly and operation of engine systems, specifically designed to enhance the stability and efficiency of the starting motor. This brace plays a significant role in the mounting and alignment of the starting motor within the engine system.

Enhanced Stability and Alignment

The Starting Motor Brace ensures that the starting motor is securely mounted and properly aligned with other engine components. This alignment is essential for the smooth operation of the starting system, as it allows the motor to engage with the flywheel or flexplate without causing undue stress or misalignment.

Vibration Dampening

One of the key functions of the Starting Motor Brace is to dampen vibrations that occur during the starting process. By providing a stable mounting point, the brace helps to absorb and distribute the forces generated by the starting motor, reducing the likelihood of component wear and fatigue.

Support During Operation

During the starting sequence, the motor undergoes significant mechanical stress. The Starting Motor Brace supports the starting motor by distributing this stress across a broader area, thereby enhancing the durability and reliability of the starting system. This support is particularly important in high-performance or high-stress engine applications where the starting motor is subjected to greater loads.

Integration with Other Components

The Starting Motor Brace works in conjunction with other components such as the starter solenoid, battery, and ignition system to ensure a seamless starting process. By providing a solid foundation for the starting motor, the brace allows these components to function more efficiently, leading to quicker and more reliable engine starts.

Maintenance and Longevity

By reducing the mechanical stress on the starting motor and other related components, the Starting Motor Brace contributes to the overall longevity of the engine system. This reduction in stress can lead to fewer maintenance requirements and extended component life, making the engine system more reliable over time.

Conclusion

The Cummins 4012069 Starting Motor Brace is a vital component that enhances the stability, efficiency, and durability of the starting motor within engine systems. Its role in mounting, alignment, vibration dampening, and support during operation makes it an essential part of any engine’s starting system.

-

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.