This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

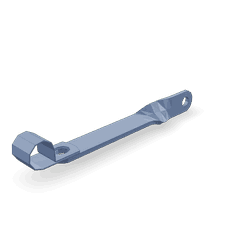

The Fastening Clip 3965089 is a specialized component designed by Cummins for use in commercial truck operations. This clip serves a role in securing various components within the truck’s engine system, ensuring they remain in place under operational conditions. Its design and functionality contribute to the overall reliability and performance of the vehicle.

Basic Concepts of Fastening Clips

Fastening clips are small components used across various automotive applications to secure parts and assemblies. They function by providing a mechanical bond that holds components in place, reducing the risk of displacement or damage during vehicle operation. These clips are typically made from durable materials to withstand the stresses and environmental conditions encountered in automotive use 1.

Purpose of Fastening Clip 3965089

The Fastening Clip 3965089 is specifically engineered to secure components within the truck’s engine system. It plays a role in maintaining the integrity of the engine’s assembly by ensuring that critical parts remain fixed in their designated positions. This clip supports the efficient operation of the truck by contributing to the stability and security of the engine components it secures.

Key Features

The Fastening Clip 3965089 features a design that includes precision-engineered contours to ensure a snug fit around the components it secures. It is constructed from high-strength materials, offering durability and resistance to wear and environmental factors. The clip’s design also incorporates features that facilitate easy installation and removal, enhancing its practicality in maintenance scenarios 2.

Benefits of Using Fastening Clip 3965089

Employing the Fastening Clip 3965089 in truck maintenance and operations offers several advantages. It provides enhanced security for components, reducing the likelihood of part displacement during operation. The clip’s design allows for straightforward installation, minimizing downtime during maintenance procedures. Additionally, its durable construction contributes to the longevity of the fastening solution, offering reliable performance over the vehicle’s operational life 3.

Installation Process

Installing the Fastening Clip 3965089 involves positioning the clip over the designated components and securing it in place. This process may require specific tools to ensure the clip is correctly fitted without damaging the components or the clip itself. Following the manufacturer’s guidelines for installation is recommended to achieve the best results and ensure the clip functions as intended.

Troubleshooting Common Issues

Common issues with fastening clips can include improper fitting, which may lead to component displacement, or damage to the clip itself. These problems can often be traced back to incorrect installation or environmental factors. Addressing these issues may involve re-evaluating the installation process, ensuring the clip is correctly positioned, or replacing the clip if it has been damaged.

Maintenance Tips

Regular checks of the Fastening Clip 3965089 are recommended to ensure its continued reliable performance. Inspecting the clip for signs of wear, damage, or displacement can help identify potential issues before they lead to more significant problems. Maintaining the clip in accordance with the manufacturer’s recommendations can prolong its life and ensure the secure fastening of components.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves commercial, industrial, and automotive markets worldwide. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of their applications. Cummins’ dedication to quality and innovation is evident in their comprehensive approach to product development and customer service 4.

Cummins Fastening Clip 3965089 Compatibility

The Cummins Fastening Clip 3965089 is a versatile component designed to fit a variety of Cummins engines. This clip is essential for securing various parts within the engine assembly, ensuring that components remain in place during operation. Below is a detailed description of the engines with which this part is compatible:

B4.5 Series

- B4.5

- B4.5 RGT

These engines, both in their standard and RGT (Regenerative Gas Turbine) configurations, utilize the 3965089 fastening clip to maintain the integrity of their internal components.

QSB4.5 Series

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

The QSB4.5 series engines, equipped with either the CM2250 EC or CM850 (CM2850) configurations, also rely on the 3965089 fastening clip for secure assembly and operation.

QSB5.9 Series

- QSB5.9 30 CM550

- QSB5.9 44 CM550

Both the QSB5.9 30 CM550 and QSB5.9 44 CM550 engines incorporate the 3965089 fastening clip to ensure that their components are properly secured and aligned.

QSB6.7 Series

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

The QSB6.7 series engines, including the CM2250, CM2350 B105, and CM850 (CM2850) configurations, all utilize the 3965089 fastening clip for maintaining the structural integrity of their assemblies.

QSB7 Series

- QSB7 CM2880 B117

The QSB7 CM2880 B117 engine also employs the 3965089 fastening clip to ensure that its components are securely fastened.

QSL8.9 and QSL9 Series

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM850 (CM2850)

The QSL8.9 CM2150 L141, QSL9 CM2250, and QSL9 CM850 (CM2850) engines are also compatible with the 3965089 fastening clip, ensuring that their internal components are properly secured and aligned.

This comprehensive compatibility of the Cummins Fastening Clip 3965089 across various engine models underscores its importance in maintaining the structural integrity and operational efficiency of these engines.

Role of Part 3965089 Fastening Clip in Engine Systems

The 3965089 Fastening Clip is a component in the assembly and securement of various engine system parts. Its primary function is to ensure that components remain firmly in place, thereby maintaining the integrity and efficiency of the engine system.

Integration with Oil Level Gauge

In the context of the oil level gauge, the 3965089 Fastening Clip plays a role in securing the gauge to the engine housing. This ensures that the gauge remains stable and accurately positioned, allowing for precise measurement of the oil level. Proper attachment is vital for the gauge to function correctly, providing reliable readings that are essential for maintaining optimal engine performance and preventing potential damage from oil starvation or overfilling.

Application in Oil Level Sensor Systems

When integrated with oil level sensor systems, the 3965089 Fastening Clip ensures that the sensor is correctly mounted. This secure attachment is necessary for the sensor to accurately detect the oil level and transmit this information to the engine control unit (ECU). Accurate oil level data is fundamental for the ECU to make informed decisions regarding oil management, thereby enhancing engine reliability and longevity.

Importance in Gauge Assembly

The fastening clip is also instrumental in the overall assembly of gauges within the engine system. By providing a robust connection point, it allows for the gauge to be installed with confidence, knowing that it will withstand the vibrations and stresses encountered during engine operation. This reliability is key to ensuring that the gauge provides consistent and accurate readings over time.

Conclusion

In summary, the Fastening Clip 3965089 is a fundamental component in the securement and functionality of oil level gauges and sensors within engine systems. Its role in maintaining the structural integrity and operational accuracy of these components cannot be overstated.

-

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Bonnick, Allan and Newbold, Derek. A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.