This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

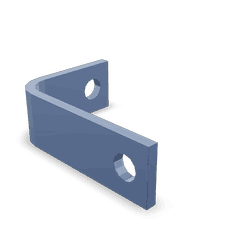

The Tube Support Brace 3094824, manufactured by Cummins, is a component designed for heavy-duty truck applications. Cummins, a well-established name in the automotive industry, produces a range of parts aimed at enhancing the performance and reliability of heavy-duty vehicles. This Cummins part is one such component, playing a significant role in the structural framework of trucks 1.

Basic Concepts of Tube Support Braces

A Tube Support Brace is a structural component used in vehicle frameworks to reinforce and stabilize tubes and other elements. Its general function is to provide additional support, ensuring the integrity and performance of the vehicle’s structure. By securing tubes and components, it helps maintain alignment and reduces the risk of structural failure under stress 2.

Purpose of the 3094824 Tube Support Brace

This part is specifically designed to support various tubes and components within a truck’s framework. It plays a role in maintaining the structural stability of the truck by securing critical tubes that may be subject to stress and vibration during operation. This support is vital for the overall durability and performance of the truck, ensuring that the framework remains intact and functions as intended 3.

Key Features

The 3094824 features a robust material composition, typically made from high-strength steel, which provides durability and resistance to wear. Its design includes precise engineering to ensure a secure fit and optimal performance. Unique attributes such as corrosion-resistant coatings may be present to enhance its functionality and longevity in various operating conditions 4.

Benefits

Using this part offers several benefits. It contributes to improved structural integrity by providing additional support to the truck’s framework. This enhancement in durability can lead to a longer service life for the vehicle. Additionally, the brace may contribute to the overall performance and safety of the truck by ensuring that critical components remain securely in place during operation 5.

Installation Considerations

Proper installation of the 3094824 is crucial for its effectiveness. Guidelines for installation include ensuring that the truck’s framework is clean and free of debris before beginning. Tools required may include wrenches, torque wrenches, and possibly a drill for any necessary modifications. Following the manufacturer’s instructions ensures correct fitting and functionality, which is vital for the brace to perform its intended role effectively 6.

Troubleshooting and Maintenance

Common issues with the 3094824 may include loosening over time due to vibration or corrosion. Regular inspections can help identify signs of wear or damage, such as rust or deformation. Maintenance tips include cleaning the brace and its mounting points, applying lubricant to moving parts if applicable, and tightening any loose connections. Addressing these issues promptly can prolong the lifespan of the brace and maintain its effectiveness 7.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long history in the automotive industry, particularly known for its diesel engines and components for heavy-duty trucks. Their range of products is designed to meet the demanding requirements of commercial and industrial applications, emphasizing reliability, performance, and durability. Cummins’ reputation is built on a commitment to quality and innovation, making them a trusted name in the industry 8.

Tube Support Brace (Part 3094824) Compatibility with Cummins Engines

The Tube Support Brace, identified by the part number 3094824, is a critical component designed to provide structural integrity and support to the engine’s exhaust system. This part is engineered to fit seamlessly with several Cummins engines, ensuring optimal performance and durability.

QST30 CM2350 T101 and QST30 CM552 Engines

The Tube Support Brace is specifically designed to integrate with the QST30 CM2350 T101 and QST30 CM552 engines. These engines, while sharing the QST30 designation, have distinct configurations that require precise fitting of the Tube Support Brace. The part ensures that the exhaust system components are securely held in place, reducing the risk of wear and tear due to vibrations and thermal expansion.

The Tube Support Brace is engineered to withstand the operational stresses of these engines, providing a robust solution for maintaining the alignment and stability of the exhaust system. Its design allows for easy installation and removal, facilitating maintenance and repair processes.

By ensuring a snug fit and reliable support, the Tube Support Brace contributes to the overall longevity and efficiency of the engines. Its compatibility with both the QST30 CM2350 T101 and QST30 CM552 engines underscores its versatility and importance in the engine’s structural framework 9.

Understanding the Role of Part 3094824 Tube Support Brace in Engine Systems

The part 3094824 is an integral component in the assembly and operation of various engine systems. Its primary function is to provide structural support and stability to the tubing and wiring that are essential for the engine’s performance.

Support for Fuel and Plumbing Systems

In fuel systems, the Tube Support Brace ensures that fuel lines are securely held in place. This is particularly important in high-vibration environments, where unsecured lines could lead to fuel leaks or reduced efficiency. Similarly, in plumbing systems, it supports coolant and oil lines, maintaining their integrity and ensuring consistent fluid flow throughout the engine 10.

Integration with Engine Control and Sensor Wiring

The Tube Support Brace plays a significant role in securing the needle-motion sensor wiring, both for the left and right bank brackets. This is vital for the accurate operation of the engine control module (ECM), as it relies on precise sensor data to adjust fuel injection and ignition timing. By keeping the wiring organized and protected, the brace helps prevent electrical interference and ensures reliable sensor readings 11.

Turbocharger and Starting Aid Support

In turbocharged engines, the Tube Support Brace supports the turbocharger’s plumbing, which includes both the intake and exhaust sides. This support is essential for maintaining the turbocharger’s efficiency and durability. Additionally, it aids in the secure placement of the starting aid, ensuring that it functions correctly during engine start-up, especially in cold conditions 12.

Mounting and Package Stability

The brace also contributes to the overall stability of the engine mounting and package. By providing a solid foundation for various components, it helps in reducing vibrations and ensuring that the engine remains securely in place within the vehicle’s chassis. This is particularly important in high-performance engines where precision and stability are paramount 13.

Conclusion

In summary, the part 3094824 Tube Support Brace is a key component in maintaining the structural integrity and operational efficiency of various engine systems. Its role in supporting fuel lines, sensor wiring, turbocharger plumbing, and overall engine stability underscores its importance in engine design and performance 14.

-

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

The Evolution of Automotive Engineering: A Handbook, Gijs Mom, SAE International, 2023

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010

↩ -

Engine: Generator Drive QSK60 G CM700 K103, Bulletin Number: 4325992, Owners Manual

↩ -

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

The Evolution of Automotive Engineering: A Handbook, Gijs Mom, SAE International, 2023

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010

↩ -

Engine: Generator Drive QSK60 G CM700 K103, Bulletin Number: 4325992, Owners Manual

↩ -

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

The Evolution of Automotive Engineering: A Handbook, Gijs Mom, SAE International, 2023

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010

↩ -

Engine: Generator Drive QSK60 G CM700 K103, Bulletin Number: 4325992, Owners Manual

↩ -

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

The Evolution of Automotive Engineering: A Handbook, Gijs Mom, SAE International, 2023

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.