This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3084222 Tube Brace is a component designed to enhance the structural integrity and performance of commercial trucks. Its role is to provide additional support and stability to the truck’s frame, ensuring that it can withstand the rigors of heavy-duty operations 1.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle construction to reinforce the frame and chassis. They function by distributing stress and load more evenly across the vehicle’s structure, which helps maintain overall integrity and durability. In commercial trucks, tube braces play a significant role in ensuring that the vehicle can handle heavy loads and rough terrain without compromising safety or performance 2.

Purpose of the 3084222 Tube Brace

The Cummins 3084222 Tube Brace is specifically designed to support the frame of commercial trucks. It plays a role in reinforcing critical areas of the truck’s structure, which helps in maintaining alignment and stability under load. By providing additional support, this tube brace contributes to the overall performance and longevity of the truck 3.

Key Features

The Cummins 3084222 Tube Brace is constructed from high-strength steel, which offers excellent durability and resistance to wear and tear. Its design includes precise welding and a robust framework that ensures it can handle significant stress. Unique characteristics of this tube brace include its compatibility with specific truck models and its ability to integrate seamlessly with existing frame structures 4.

Benefits

Using the Cummins 3084222 Tube Brace offers several advantages. It enhances structural stability by providing additional support to the truck’s frame, which can lead to improved handling and performance. The high-strength material used in its construction ensures enhanced durability, reducing the likelihood of structural failure. Additionally, by maintaining the integrity of the truck’s frame, this tube brace contributes to overall safety and reliability 5.

Installation Process

Installing the Cummins 3084222 Tube Brace requires careful preparation and the use of appropriate tools. The process involves identifying the correct mounting points on the truck’s frame, ensuring that the brace is aligned properly, and securing it in place using high-strength fasteners. It is important to follow manufacturer guidelines to ensure that the brace is fitted correctly and functions as intended 6.

Troubleshooting Common Issues

Common issues associated with tube braces include corrosion, misalignment, and structural fatigue. To address these problems, regular inspections should be conducted to identify any signs of wear or damage. Corrosion can be mitigated by applying protective coatings, while misalignment may require re-positioning or re-securing the brace. Structural fatigue can be addressed by replacing worn components and ensuring that the brace is properly maintained 7.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3084222 Tube Brace, regular maintenance is recommended. This includes routine inspections to check for signs of wear, corrosion, or damage. Cleaning the brace and applying protective coatings can help prevent corrosion. Additionally, ensuring that all fasteners are secure and that the brace remains properly aligned will contribute to its effectiveness 8.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, with a strong reputation in the commercial truck industry. The company has a history of innovation and commitment to quality, offering a wide range of products designed to enhance the performance and reliability of commercial vehicles. Cummins’ dedication to excellence is evident in their comprehensive product range, which includes components like the 3084222 Tube Brace, designed to meet the demanding needs of heavy-duty truck operations 9.

Role of Part 3084222 Tube Brace in Engine Systems

The part 3084222 Tube Brace is an essential component in the structural integrity of engine systems. It primarily functions to reinforce and stabilize various engine components, ensuring optimal performance and longevity.

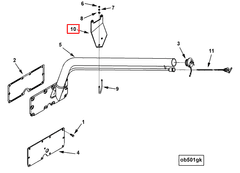

Integration with Hand Hole Cover

The Tube Brace is strategically positioned to support the Hand Hole Cover. This cover provides access to the engine’s internal components for maintenance and inspection. The brace ensures that the cover remains securely in place, preventing any unwanted movement that could lead to misalignment or damage during operation 10.

Structural Reinforcement

Beyond its role with the Hand Hole Cover, the Tube Brace offers additional reinforcement to the engine’s framework. It helps distribute loads evenly across the engine, reducing stress on individual components. This balanced load distribution is vital for maintaining the engine’s structural integrity under various operating conditions 11.

Enhanced Stability

In dynamic engine environments, the Tube Brace plays a significant role in enhancing overall stability. It minimizes vibrations and oscillations that can occur during engine operation. By doing so, it contributes to a smoother running engine, which is essential for both performance and durability 12.

Support for Other Components

The Tube Brace also provides indirect support to other engine components by maintaining the alignment and stability of the Hand Hole Cover. This, in turn, ensures that all interconnected parts function as intended, contributing to the engine’s efficiency and reliability 13.

Conclusion

In summary, the part 3084222 Tube Brace is a key element in the engine’s structural design, offering essential support and stability to critical components like the Hand Hole Cover. Its role in load distribution and vibration reduction further underscores its importance in maintaining engine performance and durability.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5579683.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5579683.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5579683.

↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5579683.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5579683.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.