This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3076248 Wiring Brace is a component designed to support and organize the wiring harnesses in commercial trucks. Its role is to maintain the integrity and efficiency of the truck’s electrical system by securing and protecting the wiring harnesses from potential damage.

Purpose and Function

The primary purpose of the Wiring Brace is to provide structural support and organization for the wiring harnesses within a truck’s electrical system. By securing the harnesses in place, it helps prevent chafing, abrasion, and other forms of physical damage that could lead to electrical faults. This organization also aids in maintaining a tidy and accessible wiring layout, which is crucial for both routine maintenance and troubleshooting 1.

Key Features

This Cummins part is constructed using durable materials that are resistant to the harsh conditions typically encountered in commercial trucking environments. Its design includes features such as mounting points and channels that allow for secure attachment and routing of wiring harnesses. These attributes contribute to the brace’s performance and longevity, ensuring it can withstand the rigors of daily use 2.

Benefits

The installation of the Wiring Brace offers several benefits. It enhances wire management by keeping harnesses organized and protected, which can reduce the likelihood of electrical faults. Additionally, by securing the wiring, it contributes to the overall reliability of the truck’s electrical system, potentially reducing downtime and maintenance costs 3.

Installation Process

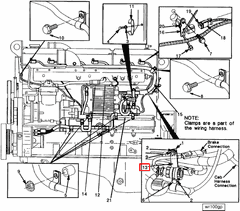

Installing the 3076248 involves several steps to ensure it is securely and effectively placed within the truck’s wiring system. The process typically requires basic hand tools. It is important to follow the manufacturer’s guidelines for placement and attachment to ensure the brace functions as intended. Proper installation involves identifying the correct location for the brace, securing it in place, and then routing the wiring harnesses through the designated channels.

Maintenance and Troubleshooting

Regular maintenance checks for the Wiring Brace are recommended to ensure its continued effectiveness. This includes inspecting the brace for signs of wear or damage and ensuring that the wiring harnesses remain securely routed. Common issues may include loose connections or damage to the brace itself. Troubleshooting typically involves re-securing any loose components or replacing damaged parts to maintain the integrity of the electrical system.

Compatibility and Usage

The 3076248 is designed for use in specific types of trucks and engine models. It is important to verify compatibility with the truck’s make and model to ensure proper fit and function. Specific installation considerations may include the need for additional components or modifications to the existing wiring system.

Safety Considerations

When installing or maintaining the Wiring Brace, it is important to observe safety guidelines to prevent electrical hazards and ensure personal safety. This includes working with the truck’s electrical system powered down and using appropriate personal protective equipment. Following these precautions helps to mitigate risks associated with electrical work.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins plays a significant role in the development and production of diesel engines and automotive components, including the 3076248 Wiring Brace. The company’s commitment to excellence is reflected in the design and performance of its products.

Wiring Brace 3076248 in Cummins Engines

The Wiring Brace 3076248, manufactured by Cummins, is a component in the electrical system of various Cummins engines. This part is designed to secure and stabilize the wiring harnesses, ensuring they remain in place and are protected from undue stress or movement.

In the N14 CELECT PLUS engine, the Wiring Brace plays a role in maintaining the integrity of the electrical connections. It is strategically positioned to prevent wires from becoming dislodged or damaged, which could lead to electrical failures or reduced engine performance.

The use of this brace is not limited to the N14 CELECT PLUS engine alone. It is also compatible with other Cummins engines within the same family or those that share similar design parameters. This compatibility ensures that the Wiring Brace can be effectively utilized across a range of engine models, providing a consistent solution for wiring management.

The installation of the Wiring Brace is straightforward, requiring minimal tools and time. It is typically mounted using screws or bolts, which allows for easy adjustment and secure fastening. This ease of installation is a significant advantage, as it minimizes downtime during maintenance or repairs.

Overall, the Wiring Brace is a component for maintaining the reliability and efficiency of Cummins engines. Its design and functionality make it a part of the engine’s electrical system, ensuring that wiring remains intact and secure under various operating conditions.

Role of Part 3076248 Wiring Brace in Engine Systems

The 3076248 Wiring Brace is a component in the integration and protection of wiring systems within engine assemblies. It serves multiple functions that enhance the reliability and efficiency of the engine’s electrical systems.

Integration with Accessories

When integrating accessories into an engine system, the 3076248 Wiring Brace plays a role. It ensures that the wiring for accessories such as alternators, fuel pumps, and sensors is securely held in place. This prevents undue stress on the wires, which can lead to fraying or disconnection. The brace also aids in organizing the wiring, making it easier to trace and diagnose issues during maintenance.

Protection of Wiring

The brace provides a protective barrier for the wiring, shielding it from potential damage caused by moving engine components or heat. This is particularly important in high-vibration environments where unsecured wiring can chafe against metal parts, leading to shorts or failures. By securing the wiring, the brace helps maintain the integrity of the electrical connections, ensuring consistent performance of the engine’s electronic systems.

Facilitation of Maintenance

During routine maintenance or repairs, the 3076248 Wiring Brace simplifies access to the wiring. It keeps the wires neatly arranged, reducing the time required to locate specific cables. This organization is vital during diagnostics, as it allows mechanics to quickly identify and address issues without unnecessary disassembly of the engine components.

Enhancement of System Reliability

By securing and organizing the wiring, the brace contributes to the overall reliability of the engine’s electrical system. It reduces the likelihood of wire fatigue, which can occur from constant movement and vibration. This results in fewer unexpected failures and enhances the durability of the engine’s electrical components.

Conclusion

In summary, the 3076248 Wiring Brace is a key component in maintaining the structural integrity and operational efficiency of the engine’s wiring system. Its role in protecting, organizing, and facilitating access to wiring is indispensable for the smooth functioning of modern engine assemblies.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.