This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3076148 Wiring Brace is a component designed to enhance the electrical system’s reliability and efficiency in commercial trucks. Its role is to support and organize the wiring harnesses, ensuring they remain secure and undamaged during operation. This part is significant for maintaining the electrical integrity of the vehicle, contributing to overall performance and safety 1.

Purpose and Function

The Cummins 3076148 Wiring Brace provides a structured framework for the wiring harnesses. It helps in organizing the wires, reducing the risk of tangling or abrasion, which can lead to electrical faults. By securing the harnesses, it ensures that the electrical connections remain intact, supporting the efficient operation of the truck’s electrical components 2.

Key Features

This Cummins part is characterized by its robust design and the materials used in its construction. It is typically made from durable plastics or metals that can withstand the harsh conditions found in commercial truck environments. Its design includes features that allow for easy integration with existing wiring systems, ensuring a snug fit that enhances performance and durability 3.

Benefits

The use of the Cummins 3076148 Wiring Brace offers several advantages. It improves wire management by keeping the harnesses organized and protected. This reduces the likelihood of electrical faults caused by wire damage. Additionally, by maintaining the integrity of the electrical system, it contributes to the longevity of the components, potentially reducing maintenance costs and downtime.

Installation

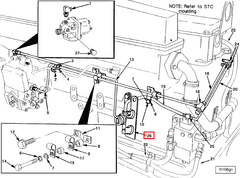

Installing the Cummins 3076148 Wiring Brace involves several steps to ensure it is correctly fitted. The process typically requires basic hand tools. It begins with identifying the correct location for the brace within the truck’s electrical system. Once positioned, the brace is secured in place using the provided fasteners. Care should be taken to ensure that all wiring is properly routed through the brace to avoid damage and ensure optimal performance.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3076148 Wiring Brace involves inspecting it for signs of wear or damage, ensuring that all fasteners are secure, and checking that the wiring remains properly routed. Common issues may include loose connections or damage to the brace itself. Troubleshooting these problems often involves tightening fasteners or replacing damaged components to maintain the electrical system’s efficiency.

Manufacturer Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products that include engines, filtration systems, and aftermarket parts. The company has a reputation for quality and reliability, backed by a history of innovation and commitment to customer satisfaction. Its product range is designed to meet the demanding requirements of commercial trucking, ensuring vehicles operate efficiently and reliably.

Role of Part 3076148 Wiring Brace in Engine Systems

The 3076148 Wiring Brace is a component in the integration and support of wiring systems within engine assemblies. Its primary function is to provide structural support and organization for the wiring harnesses that connect various accessories to the engine’s electrical system.

Integration with Accessories

When accessories such as alternators, fuel pumps, or sensors are installed, they require a reliable electrical connection to function correctly. The 3076148 Wiring Brace ensures that the wiring harnesses are securely held in place, reducing the risk of disconnection or damage due to vibrations or movement. This support is particularly important in high-performance or high-stress environments where engine components are subject to significant mechanical forces.

Wiring Organization

In complex engine systems, the number of wires can be extensive, leading to potential chaos without proper management. The 3076148 Wiring Brace plays a key role in organizing these wires, keeping them neatly bundled and away from moving parts. This organization not only enhances the aesthetic appeal of the engine bay but also improves safety by minimizing the chances of wires coming into contact with hot surfaces or sharp edges.

Enhanced Reliability

By securing and organizing the wiring, the 3076148 Wiring Brace contributes to the overall reliability of the engine’s electrical system. Consistent and secure connections are vital for the proper functioning of engine accessories, ensuring that they receive the necessary power and signals to operate efficiently. This reliability is especially important in applications where engine performance and durability are paramount.

Facilitation of Maintenance

Proper wiring management facilitated by the 3076148 Wiring Brace makes maintenance and troubleshooting more straightforward. Engineers and mechanics can easily access wiring harnesses for inspection or repair, reducing downtime and simplifying the diagnostic process. This ease of access is a significant advantage in both routine maintenance and emergency repairs.

Support During Engine Modifications

In scenarios where engine modifications are performed, such as upgrades or custom installations, the 3076148 Wiring Brace provides a stable foundation for new wiring configurations. It allows for flexible routing of additional wires while maintaining the integrity of the existing electrical system. This adaptability is beneficial for both professional mechanics and enthusiast engineers who frequently modify their engine setups.

Conclusion

The Cummins 3076148 Wiring Brace is a fundamental component in the electrical infrastructure of engine systems, offering support, organization, reliability, and ease of maintenance for wiring harnesses and connected accessories. Its robust design and integration capabilities make it an essential part for ensuring the efficient and reliable operation of commercial trucks.

-

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Aird, Forbes. Bosch Fuel Injection Systems. HP Books, 2001.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.