This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Tamper Proof Cover Brace, part number 3076013, is a component manufactured by Cummins, a prominent entity in the commercial truck industry. This Cummins part is designed to enhance the security and integrity of truck components, playing a significant role in the maintenance and operation of commercial trucks. Its purpose is to provide a secure fit for covers, preventing unauthorized access and tampering, which can lead to potential safety and operational issues.

Purpose and Function

The Tamper Proof Cover Brace serves a specific role in the operation of a truck. It is positioned to secure various covers on the truck, ensuring they remain in place under operational conditions. This part interacts with other components by providing a stable and tamper-resistant mounting point for covers, which are often used to protect sensitive parts and systems within the truck. Its placement is critical to maintaining the structural integrity and security of the truck’s components.

Key Features

The design of the Tamper Proof Cover Brace is characterized by its robust construction and material selection. Made from high-strength materials, it offers durability and resistance to tampering attempts. The part is engineered to withstand the rigors of commercial truck operation, including exposure to various environmental conditions and mechanical stresses. Its design ensures easy integration with other truck systems, providing a secure and reliable solution for cover protection.

Benefits

Incorporating the Tamper Proof Cover Brace into a truck’s design offers several advantages. Enhanced security is a primary benefit, as it deters unauthorized access to critical components 1. This part also contributes to reduced maintenance costs by preventing damage and wear that can result from tampering. Additionally, it improves operational efficiency by ensuring that covers remain securely in place, reducing the risk of component exposure and related issues.

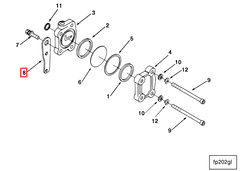

Installation Process

Installing the Tamper Proof Cover Brace requires careful attention to detail to ensure a secure fit. The process involves identifying the correct location for the brace, aligning it with the mounting points, and securing it in place using the appropriate fasteners. Tools required may include a torque wrench for tightening fasteners to the manufacturer’s specifications. Best practices for installation include verifying the brace’s alignment and ensuring all fasteners are tightened to the recommended torque settings to prevent loosening over time.

Troubleshooting Common Issues

Typical problems that may arise with the Tamper Proof Cover Brace include loosening of fasteners, damage from environmental exposure, or physical tampering attempts. Solutions to these issues involve regular inspection for signs of wear or damage, re-tightening fasteners as necessary, and replacing the brace if it shows signs of significant wear or damage. Maintenance tips to prevent future issues include protecting the brace from extreme environmental conditions and conducting regular inspections as part of the truck’s maintenance schedule.

Maintenance Recommendations

Regular inspection and maintenance of the Tamper Proof Cover Brace are crucial for ensuring its continued effectiveness and longevity. Maintenance recommendations include checking for signs of wear or damage, ensuring fasteners remain tight, and protecting the brace from environmental factors that could lead to corrosion or degradation. Following these guidelines helps maintain the security and integrity of the truck’s components.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial truck applications 2.

Tamper Proof Cover Brace (Part 3076013) Compatibility with Cummins Engines

The Tamper Proof Cover Brace, identified by part number 3076013, is a critical component designed to secure and protect engine covers. This part is engineered to fit seamlessly with a variety of Cummins engines, ensuring robust protection and integrity of the engine’s cover system.

Mechanical Engines

The Tamper Proof Cover Brace is compatible with several mechanical engines within the Cummins lineup. Specifically, it fits the L10 MECHANICAL and M11 MECHANICAL engines. These engines are known for their durability and reliability, often used in heavy-duty applications where robust engine protection is essential.

Select Plus Engines

The part also fits the M11 CELECT PLUS engine, which is an advanced version of the M11 MECHANICAL engine. The CELECT PLUS designation indicates enhanced features and capabilities, including improved electronic controls and diagnostics. The Tamper Proof Cover Brace ensures that the enhanced features of the M11 CELECT PLUS are protected against unauthorized access and tampering.

N14 MECHANICAL Engine

The Tamper Proof Cover Brace is also designed to fit the N14 MECHANICAL engine. This engine is another robust option in Cummins’ mechanical lineup, often utilized in applications requiring high power output and reliability. The cover brace provides essential security for the engine’s cover, safeguarding it from potential damage or tampering.

Cummins QSK Engines

For the Cummins QSK engines, the Tamper Proof Cover Brace is compatible with both the QSK45 CM500 and QSK60 CM500 models. These engines are part of Cummins’ QSK series, known for their high performance and efficiency. The cover brace ensures that the engine covers on these models remain secure, protecting the internal components from unauthorized access and potential damage.

Role of Part 3076013 Tamper Proof Cover Brace in Engine Systems

The Tamper Proof Cover Brace, part 3076013, is integral to the structural integrity and security of various engine components. It ensures that the components remain securely in place and are resistant to unauthorized tampering.

In systems involving the Fuel Filter and Damper, the brace provides additional support to maintain the alignment and stability of the components, ensuring efficient fuel flow and dampening of pressure fluctuations.

When integrated with the Fuel Pump and Fuel Pump and Mounting Damper, the brace helps in securing the pump assembly. This is particularly important in high-vibration environments where the stability of the fuel pump is essential for consistent fuel delivery.

For the Gear Fuel Pump, the brace offers reinforcement, reducing the risk of mechanical stress that could lead to pump failure. It also plays a role in maintaining the precise alignment needed for optimal performance.

In configurations with the Head and Damper Fuel Filter, the brace ensures that the filter housing remains intact and secure, preventing any potential leaks or disruptions in the fuel line.

Additionally, in systems with the Pump, Fuel, and Pump, Fuel Base, the brace contributes to the overall robustness of the fuel system, safeguarding against physical damage and ensuring that the pump operates within specified parameters.

Finally, for the Pump, Fuel Injection systems, the brace is vital in maintaining the integrity of the injection components. It ensures that the fuel injection process remains precise and unaffected by external vibrations or tampering attempts 3.

Conclusion

The Tamper Proof Cover Brace, part number 3076013, is a versatile and essential component in the maintenance and operation of Cummins engines. Its robust design and compatibility with a range of Cummins engines ensure that engine covers remain secure and protected, maintaining the integrity and reliability of the engines. Regular maintenance and inspection of this part are recommended to ensure its continued effectiveness and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.