This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3054895 Tube Brace is a component designed for heavy-duty trucks, enhancing the structural integrity and performance of these vehicles. It provides additional support and stability to the truck’s frame, contributing to overall durability and safety.

Basic Concepts of Tube Braces

A tube brace is a structural component used in vehicle construction to reinforce the frame and improve rigidity. By connecting different parts of the vehicle’s frame, tube braces help distribute loads more evenly and reduce the risk of frame flex or failure under stress. This reinforcement is particularly important in heavy-duty trucks, which often carry substantial loads and operate in demanding conditions 1.

Purpose of the Cummins 3054895 Tube Brace

The Cummins 3054895 Tube Brace is specifically designed to enhance the stability and durability of heavy-duty trucks. It plays a role in the structural integrity of the truck by providing additional support to the frame. This support helps in maintaining the alignment and strength of the truck’s chassis, which is crucial for safe and efficient operation. The brace contributes to the overall performance by ensuring that the truck can withstand the stresses of heavy loads and rough terrain 2.

Key Features

The Cummins 3054895 Tube Brace is constructed from high-strength materials, ensuring durability and reliability. Its design includes precise engineering to fit seamlessly with the truck’s frame, offering optimal support without compromising on the vehicle’s performance. Unique characteristics of this tube brace may include its specific shape and size, tailored to fit particular truck models, and its ability to integrate with other components for enhanced functionality 3.

Benefits

Using the Cummins 3054895 Tube Brace offers several advantages. It improves structural rigidity, which is vital for maintaining the truck’s frame integrity under heavy loads. Enhanced safety is another benefit, as a more rigid frame is less likely to flex or fail, reducing the risk of accidents. Additionally, the brace may contribute to an increase in the truck’s load-carrying capacity, allowing it to transport heavier loads without compromising safety or performance.

Installation Considerations

Proper installation of the Cummins 3054895 Tube Brace is crucial for ensuring its effectiveness. Guidelines for installation include checking the truck’s frame for any existing damage or misalignment before proceeding. Special tools may be required to securely attach the brace to the frame, ensuring it is properly aligned and tightened to the manufacturer’s specifications. Following these guidelines helps in maximizing the brace’s benefits and ensuring the truck’s structural integrity.

Troubleshooting and Maintenance

Common issues with tube braces may include corrosion, misalignment, or damage from impacts. Troubleshooting these problems involves inspecting the brace for signs of wear or damage and addressing any issues promptly to prevent further deterioration. Maintenance tips for the Cummins 3054895 Tube Brace include regular inspections for corrosion or damage, ensuring it remains securely attached, and addressing any issues as they arise to maintain the truck’s structural integrity and performance.

Cummins Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a history of developing reliable and high-performance components, Cummins has built a reputation for excellence in the field. The company’s dedication to advancing truck technology is evident in its wide range of products, designed to meet the demanding requirements of heavy-duty applications.

Role of Part 3054895 Tube Brace in Engine Systems

The 3054895 Tube Brace is integral to the structural integrity and efficient operation of various engine systems. It provides essential support and stability to several components, ensuring they function optimally under the demanding conditions of engine operation.

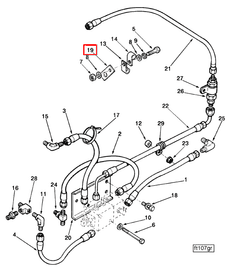

Support for Plumbing and Tubing Systems

The Tube Brace plays a significant role in supporting the EBM (Engine Bay Management) plumbing and tubing systems. It secures fuel lines, coolant passages, and other fluid conduits, preventing undue stress and potential leaks. This support is vital for maintaining the integrity of the fuel supply and ensuring consistent delivery to the injectors.

Reinforcement of Wiring and Harnesses

In addition to fluid systems, the Tube Brace offers reinforcement for wiring harnesses and electrical connections. By stabilizing these components, it reduces the risk of wire fatigue and electrical failures, which can be detrimental to the engine control module (ECM) and other electronic systems.

Stability for Mounting and Step Plumbing

The Tube Brace is also instrumental in the stability of mounting and step plumbing arrangements. It ensures that components like the step valve plumbing and stud mounting plumbing remain securely in place. This stability is essential for the precise operation of the injector and other critical engine parts.

Integration with Compressor Coolant and Accessories

Furthermore, the Tube Brace aids in the secure arrangement of compressor coolant systems and various engine accessories. It helps maintain the alignment and efficiency of these components, contributing to the overall performance and reliability of the engine.

Enhanced Structural Integrity

By providing a robust framework for these diverse engine systems, the Tube Brace enhances the structural integrity of the engine bay. This support allows for better management of the complex interplay between mechanical, electrical, and fluid systems, ultimately leading to more reliable engine performance.

Conclusion

The Cummins 3054895 Tube Brace is a vital component for heavy-duty trucks, offering enhanced structural integrity, improved safety, and increased load-carrying capacity. Proper installation and maintenance are essential to maximize its benefits and ensure the truck’s performance and durability.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.