This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 3042454 Tube Brace is a component manufactured by Cummins, a well-established name in the commercial truck industry. This Cummins part is designed to enhance the structural integrity of commercial trucks, ensuring they can withstand the rigors of heavy-duty operations.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle frameworks to provide additional support and rigidity. They connect various parts of the chassis, distributing loads more evenly and reducing stress on individual components. This reinforcement contributes to the overall durability and safety of the vehicle 1.

Purpose of the 3042454 Tube Brace

The 3042454 Tube Brace is specifically engineered to bolster the structural framework of commercial trucks. It plays a role in maintaining the chassis’s integrity under heavy loads and dynamic driving conditions. By providing additional support, it helps in preserving the alignment and stability of the truck, which is vital for safe operation.

Key Features

The 3042454 is constructed from high-strength steel, ensuring durability and resistance to wear and tear. Its design includes precision-engineered joints that allow for easy installation while maintaining a secure fit. Additionally, the brace features a corrosion-resistant coating, which enhances its longevity in various environmental conditions.

Benefits

Installing the 3042454 offers several advantages. It enhances the structural rigidity of the truck, which can lead to improved handling and stability. Additionally, the brace contributes to the overall safety of the vehicle by reducing the risk of chassis failure under stress. It may also support an increase in the truck’s load-carrying capacity, making it a valuable addition for heavy-duty applications.

Installation Process

To install the 3042454, begin by ensuring the truck is on a level surface and the engine is off. Use the appropriate tools to remove any existing components that may interfere with the brace’s placement. Align the brace with the designated mounting points on the chassis and secure it using the provided fasteners. Double-check all connections to ensure they are tight and secure.

Troubleshooting Common Issues

Common issues with the 3042454 may include loose connections or corrosion. To address these, regularly inspect the brace and its mounting points. Tighten any loose fasteners and apply a corrosion-resistant coating if necessary. If significant corrosion is present, consider replacing the affected parts to maintain the brace’s effectiveness.

Maintenance Tips

Regular maintenance of the 3042454 involves inspecting it for signs of wear, corrosion, or damage. Clean the brace periodically to remove dirt and debris that could accelerate corrosion. Ensure that all fasteners remain tight and that the brace is securely attached to the chassis. Following these maintenance practices will help ensure the longevity and optimal performance of the tube brace.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. Their product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Application in Cummins Engines

N14 Mechanical Engines

In the N14 Mechanical engines, the 3042454 plays a role in securing the engine’s internal tubes and brackets. This ensures that the engine’s components remain properly aligned and supported, reducing the risk of mechanical failure and enhancing overall efficiency.

NH/NT 855 Engines

Similarly, in the NH/NT 855 engines, the 3042454 is integral to maintaining the structural integrity of the engine. It provides the necessary support to the internal tubes and brackets, ensuring that the engine operates smoothly and reliably. This part is instrumental in preventing misalignment and wear, which can lead to costly repairs and downtime.

Grouping of Engines

The 3042454 is applicable across a range of Cummins engines, including the N14 Mechanical and NH/NT 855 models. This part’s design and functionality make it a versatile component that can be used in various engine configurations, providing consistent support and stability.

Role of 3042454 in Engine Systems

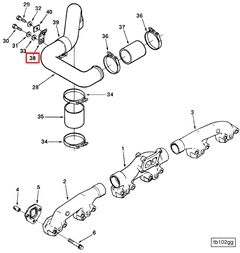

Air Crossover Mounting

In systems where an air crossover is utilized, the Tube Brace provides necessary support. It helps in maintaining the alignment and stability of the air crossover, which is vital for efficient airflow management. Proper alignment ensures that the air crossover can effectively distribute air to different parts of the engine, enhancing combustion efficiency and overall engine performance 2.

Turbocharger Support

The Tube Brace is instrumental in the mounting and support of turbochargers. Turbochargers operate under high stress and temperatures, and the Tube Brace helps in absorbing and distributing these stresses. This support is essential for maintaining the turbocharger’s alignment and operational efficiency, directly impacting the engine’s power output and responsiveness.

Turbocharger Mounting

When it comes to turbocharger mounting, the Tube Brace offers additional reinforcement. It ensures that the turbocharger is securely mounted, reducing the risk of movement or misalignment during operation. This stability is crucial for the turbocharger’s longevity and performance, as any shift can lead to decreased efficiency and potential damage.

Conclusion

The 3042454 Tube Brace is a key component in enhancing the structural integrity and performance of engine systems, particularly in supporting the air crossover, turbocharger, and turbocharger mounting. Its role in maintaining component alignment and absorbing operational stresses is fundamental to the efficient and reliable operation of modern engines 3.

-

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.