This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

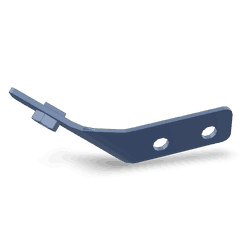

The 2888036 Tube Brace, a component manufactured by Cummins, is designed specifically for use in commercial trucks. This part plays a significant role in the structural integrity and operational efficiency of these vehicles. Cummins, a renowned name in the diesel engine and component manufacturing industry, produces this tube brace to meet the demanding requirements of heavy-duty truck applications.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle construction to reinforce frames and other critical areas. They contribute to the overall strength and stability of a vehicle by distributing stress and preventing deformation under load. In commercial trucks, tube braces are essential for maintaining the vehicle’s structural integrity, especially under heavy loads or in challenging driving conditions 1.

Purpose of the 2888036 Tube Brace

The 2888036 Tube Brace is designed to enhance the structural stability of a truck’s frame or engine compartment. Its strategic placement aims to support areas prone to stress or wear. By reinforcing these sections, the tube brace helps maintain the truck’s structural integrity, which is vital for safety and performance.

Key Features

This Cummins part is constructed from high-quality materials, ensuring durability and resistance to the harsh conditions often encountered in commercial trucking. Its design specifications include precise dimensions and a robust construction that allows it to effectively distribute stress across the truck’s frame. Unique attributes of this tube brace may include corrosion-resistant coatings or specialized welding techniques that enhance its performance and longevity.

Benefits of Using the 2888036 Tube Brace

Incorporating the 2888036 Tube Brace into a truck’s design offers several advantages. It contributes to improved structural integrity, which can lead to enhanced safety for the vehicle’s occupants and cargo. Additionally, by reinforcing critical areas, this tube brace may help increase the operational efficiency and longevity of the truck, potentially reducing maintenance costs and downtime.

Installation Considerations

Proper installation of the 2888036 Tube Brace is crucial for its effective performance. This process may require specific tools and adherence to manufacturer guidelines to ensure correct fitting and functionality. It is important to follow the recommended procedures to avoid issues such as improper alignment or insufficient tightening, which could compromise the brace’s effectiveness.

Troubleshooting Common Issues

Common problems associated with the 2888036 Tube Brace may include corrosion, wear, or issues arising from improper installation. Regular inspections can help identify these issues early. Troubleshooting steps may involve cleaning and reapplying protective coatings to address corrosion, or making adjustments to ensure proper fit and function. In cases of significant wear or damage, replacement of the tube brace may be necessary.

Maintenance Tips

To ensure the continued effective performance of the 2888036 Tube Brace, regular maintenance is recommended. This includes routine inspections for signs of wear, corrosion, or damage. Cleaning the brace and reapplying protective coatings can help prevent corrosion. Additionally, ensuring that all connections are secure and that the brace remains properly aligned with the truck’s frame are important maintenance practices.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry, known for its innovation, quality, and commitment to customer satisfaction. The company’s expertise in diesel engines and components is reflected in its product offerings, which are designed to meet the rigorous demands of commercial applications.

Compatibility of Tube Brace Part 2888036 with Cummins Engines

The Tube Brace part number 2888036, manufactured by Cummins, is designed to provide structural support and stability within the engine compartment. This part is engineered to fit seamlessly with several Cummins engine models, ensuring optimal performance and longevity.

ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250

The Tube Brace part 2888036 is compatible with the ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250 engines. These engines are known for their robust design and high performance, often used in heavy-duty applications. The Tube Brace ensures that the engine remains securely mounted, reducing vibrations and enhancing overall durability.

X12 CM2350 X119B

Similarly, the Tube Brace part 2888036 is also suitable for the X12 CM2350 X119B engine. This engine variant is designed to deliver exceptional power and efficiency, making it a popular choice in various industrial applications. The Tube Brace plays a significant role in maintaining the structural integrity of the engine, ensuring that it operates smoothly under demanding conditions.

By providing a stable mounting point, the Tube Brace part 2888036 helps mitigate the effects of engine movement, thereby extending the lifespan of the engine and reducing the likelihood of mechanical failures.

Role of Part 2888036 Tube Brace in Engine Systems

The 2888036 Tube Brace is a component in maintaining the structural integrity and operational efficiency of various engine systems. It plays a significant role in supporting and stabilizing critical components, ensuring they function optimally under the demanding conditions of engine operation.

Support for Gauges

In engine systems, gauges are vital for monitoring various parameters such as temperature, pressure, and fluid levels. The 2888036 Tube Brace provides necessary support to these gauges, ensuring they remain securely in place. This support is particularly important in high-vibration environments, where gauges can become dislodged or damaged, leading to inaccurate readings or complete failure. By stabilizing the gauges, the Tube Brace helps maintain the accuracy and reliability of the readings, which are essential for proper engine management 2.

Stabilization of Oil Level Sensors

Oil level sensors are another component where the 2888036 Tube Brace proves invaluable. These sensors are responsible for monitoring the oil level within the engine, providing critical data to the engine control unit (ECU). The Tube Brace ensures that the oil level sensors remain firmly positioned, preventing any movement that could lead to incorrect oil level readings. Accurate oil level monitoring is essential for preventing engine damage due to low oil levels or overfilling, both of which can have severe consequences on engine performance and longevity 3.

Enhanced Durability and Reliability

By providing robust support and stabilization, the 2888036 Tube Brace contributes to the overall durability and reliability of the engine system. It helps in reducing the wear and tear on gauges and sensors, extending their operational life and ensuring consistent performance. This, in turn, leads to more reliable engine operation and fewer instances of unexpected failures.

Improved Safety and Performance

The stability offered by the 2888036 Tube Brace also enhances the safety and performance of the engine. Accurate and reliable readings from gauges and sensors allow for better engine management, leading to optimized performance and efficiency. Additionally, the reduced risk of component failure contributes to safer engine operation, minimizing the potential for hazardous situations.

Conclusion

The 2888036 Tube Brace is a key component in ensuring the structural integrity and operational efficiency of engine systems. Its role in supporting gauges and stabilizing oil level sensors is fundamental to maintaining accurate readings and reliable engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.