This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 214482 Tube Brace, manufactured by Cummins, is a critical component in the automotive industry, specifically for commercial trucks. This part ensures the structural integrity and operational efficiency of these vehicles 1.

Purpose of the 214482 Tube Brace

This Cummins part is essential for maintaining the structural integrity and operational efficiency of commercial trucks. It supports various components within the truck’s framework, contributing to the vehicle’s overall performance and safety. By reinforcing the truck’s structure, it aids in distributing loads more effectively and reduces the risk of structural failure under stress 2.

Key Features

The 214482 is characterized by its robust design and high-quality material composition. Crafted from durable materials, it is engineered to withstand the rigors of commercial truck operations. Its design is tailored to integrate seamlessly with the truck’s existing framework, offering enhanced stability and support. Unique attributes such as corrosion resistance and high tensile strength further enhance its functionality and durability 3.

Benefits

Incorporating the 214482 into a commercial truck’s design offers several advantages. It improves structural stability, allowing the truck to handle heavier loads with greater confidence. Additionally, by ensuring the structural integrity of the truck, it may contribute to fuel efficiency by reducing the strain on the engine and other components. Its durability also extends the longevity of the truck, providing reliable performance over time.

Installation Process

Installing the 214482 requires careful attention to detail to ensure optimal performance and safety. The process involves several preparatory steps, including ensuring the truck’s framework is clean and free of any debris. Specific tools may be required for a precise installation. Following the manufacturer’s guidelines is crucial to achieve the best results, ensuring the brace is securely fastened and properly aligned.

Maintenance and Care

Routine inspection, cleaning, and maintenance of the 214482 are recommended to prolong its lifespan and ensure continued reliable performance. Regular checks for signs of wear or damage, such as corrosion or fatigue, are important. Addressing these issues promptly can prevent more significant problems down the line, maintaining the structural integrity of the truck.

Troubleshooting Common Issues

Common issues associated with the 214482 may include corrosion, fatigue, or misalignment. Identifying these problems early is key to maintaining the truck’s performance and safety. Suggested solutions range from cleaning and reapplying protective coatings to address corrosion, to more involved repairs or replacements in cases of significant fatigue or misalignment.

Compatibility and Applications

The 214482 is designed for specific types of commercial trucks, integrating seamlessly with their existing components and systems. Its application is tailored to enhance the structural integrity and operational efficiency of these vehicles, ensuring they meet the demands of commercial use.

Safety Considerations

When working with the 214482, adhering to safety protocols is paramount. This includes proper handling, installation, and maintenance practices to mitigate risks and ensure operator safety. Following manufacturer guidelines and using appropriate personal protective equipment (PPE) are essential steps in maintaining a safe working environment.

Cummins: Manufacturer Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, with a strong reputation for producing high-quality components for commercial vehicles. The company’s history is marked by a commitment to innovation, quality, and customer satisfaction, making it a trusted name in the field of commercial truck components.

Compatibility with Various Engines

The 214482 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and longevity. It is compatible with the K19, L10 MECHANICAL, N14 MECHANICAL, and NH/NT 855 engines, providing essential support to the engine’s internal components and contributing to its overall performance and lifespan.

Role of 214482 in Engine Systems

The 214482 is instrumental in maintaining the structural integrity and operational efficiency of several key components within engine systems.

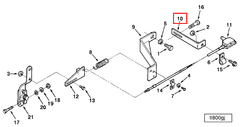

Throttle Lever and Throttle Linkage

The Tube Brace provides essential support and stability to the throttle lever and throttle linkage, ensuring smooth and consistent operation, which is vital for precise control over the engine’s power output.

Lever Mechanisms

For lever mechanisms within the engine system, the Tube Brace reinforces the structural framework, supporting the lever’s movement by providing a rigid connection point. This reinforcement helps in preventing undue flexing or misalignment of the lever, ensuring correct function under various operating conditions.

Overall System Integration

Incorporating the Tube Brace into these components enhances their individual performance and contributes to the overall stability of the engine system. It acts as a pivotal support structure that interconnects different parts, allowing them to work in unison with minimal risk of mechanical failure. This integration is key to achieving optimal engine performance and longevity.

Conclusion

The 214482 Tube Brace is a vital component for the structural integrity and operational efficiency of commercial trucks and their engines. Its robust design, compatibility with various Cummins engines, and role in supporting key engine components make it an indispensable part in maintaining the performance and longevity of these vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.