This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

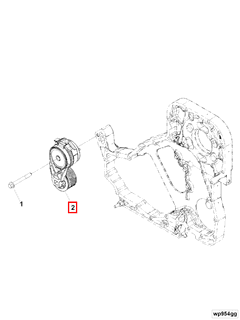

The Cummins 3976627 Belt Tensioner is a component designed to maintain the proper tension on drive belts within commercial truck engines. Its role is significant in ensuring the efficient operation of various engine-driven accessories, such as alternators, water pumps, and air conditioning compressors.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep drive belts at the correct tension. It operates by applying force to the belt, ensuring it remains snug against the pulleys it drives. Proper belt tension is vital for the efficient transfer of power from the engine to these accessories, preventing slippage and ensuring consistent performance 1.

Purpose of the 3976627 Belt Tensioner

This Cummins part is specifically engineered to maintain the correct tension on the drive belts of a truck’s engine. By doing so, it plays a role in the reliable operation of engine-driven accessories, contributing to the overall efficiency and performance of the vehicle.

Key Features

The 3976627 Belt Tensioner boasts several key features that enhance its performance. Its design incorporates high-quality materials to ensure durability and reliability. Unique characteristics, such as its precision-engineered components, contribute to its effectiveness in maintaining optimal belt tension.

Benefits of Using the 3976627 Belt Tensioner

Utilizing this Cummins part offers several advantages. It contributes to improved engine efficiency by ensuring belts operate at the correct tension, reducing the likelihood of slippage. This, in turn, leads to reduced wear on belts and accessories, enhancing the overall reliability of the engine system 2.

Installation Considerations

When installing the 3976627 Belt Tensioner, it is important to follow guidelines and best practices to ensure proper functionality. This may include adhering to specific torque specifications and ensuring the tensioner is correctly aligned with the belts and pulleys. Cummins provides recommendations to facilitate a smooth installation process.

Troubleshooting Common Issues

Common problems associated with belt tensioners can include noise, vibration, or belt slippage. Diagnosing these issues may involve inspecting the tensioner for signs of wear or damage, checking belt alignment, and ensuring the tensioner is applying the correct amount of force to the belt. Recommended solutions may range from adjustments to replacement, depending on the severity of the issue 3.

Maintenance Tips

To ensure the optimal performance of the 3976627 Belt Tensioner, regular maintenance is advised. This includes inspecting the tensioner and belts at recommended intervals, looking for signs of wear or damage, and performing any necessary adjustments or replacements. Adhering to these maintenance procedures can help prolong the life of the tensioner and ensure the efficient operation of the engine system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the commercial truck industry, Cummins is renowned for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and reputation for reliability make it a preferred choice among commercial truck operators and manufacturers.

Belt Tensioner 3976627 Compatibility with Cummins Engines

The Belt Tensioner part number 3976627, manufactured by Cummins, is designed to fit a range of Cummins engines. This part is crucial for maintaining the proper tension of the engine’s accessory belts, ensuring efficient operation and longevity of the engine components.

Compatibility with Specific Cummins Engines

-

6C8.3: The Belt Tensioner 3976627 is compatible with the 6C8.3 engine. This part ensures that the belts driving the engine’s accessories, such as the alternator and water pump, are kept at the correct tension, preventing slippage and ensuring optimal performance.

-

QSC8.3 CM554 and QSC8.3 CM850 (CM2850): Both the QSC8.3 CM554 and QSC8.3 CM850 (CM2850) engines are designed to work with the Belt Tensioner 3976627. This part is essential for maintaining the integrity of the belt system in these engines, which are commonly used in various industrial and commercial applications.

-

QSL8.9 CM2150 L141 and QSL9 CM850 (CM2850): The Belt Tensioner 3976627 is also suitable for the QSL8.9 CM2150 L141 and QSL9 CM850 (CM2850) engines. These engines benefit from the precise tensioning provided by this part, ensuring that the belts operate efficiently and reliably.

By ensuring that the Belt Tensioner 3976627 is correctly installed, operators can maintain the performance and reliability of their Cummins engines, reducing the risk of belt failure and associated downtime.

Role of Part 3976627 Belt Tensioner in Engine Systems

Part 3976627, the Belt Tensioner, is an essential component in maintaining the proper operation of various engine systems. Its primary function is to ensure that the belt remains taut, which is necessary for the efficient transfer of power and rotation of engine accessories.

Interaction with the Belt

The Belt Tensioner works in conjunction with the belt to maintain consistent tension. This is important because a loose belt can slip, leading to inefficient operation of components such as the alternator, water pump, and air conditioning compressor. Proper tension ensures these accessories receive the necessary power to function correctly, thereby maintaining engine performance and reliability.

Ensuring Smooth Operation

By keeping the belt properly tensioned, the Belt Tensioner helps to reduce wear and tear on both the belt and the pulleys it contacts. This results in a smoother operation of the engine system, minimizing the risk of belt failure and extending the lifespan of the belt and related components.

Contribution to Engine Efficiency

Efficient belt tension directly impacts engine efficiency. When the belt is correctly tensioned, it ensures that the engine accessories operate at their optimal levels. This means better charging of the battery, more effective cooling of the engine, and improved performance of the air conditioning system, all of which contribute to the overall efficiency and reliability of the engine.

Reduction of Noise and Vibration

A properly tensioned belt operates quietly and with minimal vibration. The Belt Tensioner plays a key role in this by automatically adjusting the tension as the engine operates under different loads and conditions. This not only enhances the driving experience by reducing unwanted noise but also helps in diagnosing potential issues early, as unusual noises or vibrations can indicate a problem with the belt or tensioner.

Support for Variable Systems

In engines with variable systems, such as variable valve timing or variable displacement, the Belt Tensioner ensures that the belt can accommodate changes in engine operation without losing tension. This adaptability is vital for the seamless integration of these advanced technologies into the engine’s operation.

Conclusion

In summary, the 3976627 Belt Tensioner is a fundamental component that ensures the belt operates efficiently within the engine system, supporting the function of various accessories and contributing to the overall performance and longevity of the engine.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.