The Cummins 3936205 Belt Tensioner is a component designed to maintain the proper tension on drive belts within commercial truck engines. Its role is significant in ensuring the efficient operation of various engine-driven accessories, such as alternators, water pumps, and air conditioning compressors 1.

Basic Concepts of Belt Tensioners

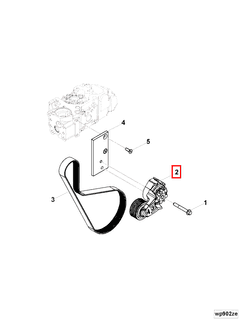

A belt tensioner is a device used in an engine system to keep drive belts at the correct tension. It functions by applying force to the belt, ensuring it remains snug against the pulleys it drives. Maintaining proper belt tension is important for the efficient transfer of power from the engine to these accessories, reducing slippage and wear 2.

Purpose of the Cummins 3936205 Belt Tensioner

The Cummins 3936205 Belt Tensioner plays a role in the operation of a truck by maintaining the correct tension on drive belts. This ensures that the belts grip the pulleys effectively, allowing for the smooth and efficient operation of engine-driven accessories. Proper tensioning helps in minimizing belt wear, reducing the risk of belt failure, and ensuring consistent performance of the accessories 3.

Key Features

The Cummins 3936205 Belt Tensioner incorporates several design elements and materials that enhance its performance. It is constructed from durable materials to withstand the harsh conditions within a truck engine. Its design includes features that allow for easy adjustment and maintenance, ensuring it can be quickly and effectively serviced when needed.

Benefits of Using the Cummins 3936205 Belt Tensioner

Using the Cummins 3936205 Belt Tensioner offers several advantages. It contributes to improved engine efficiency by ensuring that drive belts operate at optimal tension. This reduces wear on the belts and the accessories they drive, leading to enhanced reliability and longevity of the engine components. Additionally, proper belt tensioning can lead to smoother operation of engine accessories, reducing noise and vibration.

Installation Considerations

For the proper installation of the Cummins 3936205 Belt Tensioner, it is important to follow specific guidelines. This includes ensuring that the tensioner is correctly aligned with the drive belts and pulleys, and that it is securely fastened. Attention should be paid to any manufacturer recommendations regarding torque settings and alignment to ensure optimal performance.

Troubleshooting Common Issues

Common problems associated with belt tensioners can include excessive noise, belt slippage, or premature belt wear. These issues may be caused by incorrect tension settings, wear on the tensioner components, or misalignment. Troubleshooting steps may involve checking the tensioner’s alignment, inspecting for wear or damage, and adjusting the tension as necessary.

Maintenance Tips

Regular maintenance of the Cummins 3936205 Belt Tensioner is important for ensuring optimal performance and longevity. This includes periodic inspection for signs of wear or damage, ensuring that the tensioner is correctly aligned and tensioned, and replacing the tensioner or belts as recommended by the manufacturer. Following these maintenance tips can help prevent unexpected failures and ensure the efficient operation of the engine accessories.

Role of 3936205 Belt Tensioner in Engine Systems

The 3936205 Belt Tensioner is an essential component in maintaining the efficiency and reliability of various engine systems. It ensures that the drive belt remains properly tensioned, which is vital for the optimal operation of several key components.

Drive System

In the drive system, the Belt Tensioner plays a significant role by maintaining the correct tension on the drive belt. This ensures that power is efficiently transferred from the engine to the driven components, such as the alternator and water pump. Proper tension prevents slippage, which can lead to inefficient power transmission and potential damage to the belt or driven components.

Alternator

The alternator relies on a consistently tensioned belt to function correctly. The Belt Tensioner ensures that the drive belt remains in firm contact with the alternator pulley. This consistent tension is necessary for the alternator to generate electricity efficiently, which is essential for powering the vehicle’s electrical systems and recharging the battery.

Pulley System

Within the pulley system, the Belt Tensioner helps to maintain the appropriate tension across all pulleys. This is important for the smooth operation of the engine’s auxiliary systems. Whether it’s the alternator pulley, water pump pulley, or any other pulley in the system, the Belt Tensioner ensures that the belt does not become too loose or too tight, which could otherwise lead to wear, noise, or failure of the belt and pulleys.

Water Pump Drive

The water pump drive belt is another area where the Belt Tensioner is vital. Proper tension on the belt ensures that the water pump operates efficiently, providing consistent coolant flow through the engine. This is important for maintaining optimal engine temperature and preventing overheating, which can cause severe engine damage.

Conclusion

The Cummins 3936205 Belt Tensioner is a critical component in the maintenance and operation of commercial truck engines. By ensuring proper belt tension, it contributes to the efficient and reliable operation of engine-driven accessories, enhancing overall engine performance and longevity.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.