The Cummins 3922900 Belt Tensioner is a component designed for use in commercial trucks. Its purpose is to maintain the correct tension on the engine’s drive belts, ensuring efficient operation of various engine components. This tensioner plays a role in the overall performance and reliability of the truck’s engine system 1.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep the drive belts at the proper tension. It operates by applying consistent pressure to the belt, which prevents slippage and ensures that power is effectively transmitted to components such as the alternator, water pump, and air conditioning compressor. Maintaining proper belt tension is important for the longevity and efficiency of both the belts and the components they drive 2.

Purpose of the Cummins 3922900 Belt Tensioner

The Cummins 3922900 Belt Tensioner is specifically designed to maintain optimal belt tension in commercial truck engines. By ensuring that the belts are neither too tight nor too loose, this tensioner helps in the smooth operation of engine accessories. It contributes to the efficient transfer of power, reduces the risk of belt wear, and supports the overall reliability of the engine system 3.

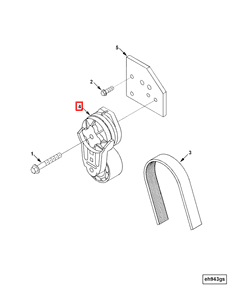

Key Features

The Cummins 3922900 Belt Tensioner is characterized by its robust design and the use of high-quality materials. These features enhance its performance and durability in the demanding environment of a commercial truck engine. The tensioner is engineered to withstand high loads and operate efficiently under varying conditions, ensuring consistent belt tension and reliable engine performance.

Benefits

Using the Cummins 3922900 Belt Tensioner offers several benefits. It contributes to improved engine performance by ensuring that drive belts operate at optimal tension. This results in reduced wear on both the belts and the components they drive. Additionally, the tensioner enhances the reliability of the engine system, leading to fewer maintenance issues and longer service intervals.

Installation and Compatibility

Proper installation of the Cummins 3922900 Belt Tensioner is important for its effective operation. Installation procedures may vary depending on the specific truck model, and it is important to follow manufacturer guidelines to ensure correct fitment and function. Compatibility with various truck models should be verified to ensure optimal performance and integration within the engine system.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3922900 Belt Tensioner includes regular inspection for signs of wear or damage, and ensuring that it operates smoothly without excessive noise or vibration. Lubrication recommendations should be followed to maintain the tensioner’s moving parts. Common troubleshooting tips for issues such as belt slippage or tensioner failure involve checking the tensioner’s alignment, condition of the belts, and ensuring that all components are properly installed and functioning as intended.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its high-quality components for commercial vehicles. With a history of innovation and a commitment to excellence, Cummins has built a reputation for producing reliable and durable parts that meet the demanding requirements of commercial truck engines. The company’s dedication to quality and performance is evident in its wide range of products, including the Cummins 3922900 Belt Tensioner.

Belt Tensioner 3922900 Compatibility with Cummins Engines

The Belt Tensioner part number 3922900, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral for maintaining the proper tension of the engine’s serpentine belt, ensuring efficient operation and longevity of the belt and related components.

Cummins 4B3.9 and 6B5.9 Engines

The Belt Tensioner 3922900 is compatible with the Cummins 4B3.9 and 6B5.9 engines. These engines are known for their robust performance and are often used in heavy-duty applications. The tensioner ensures that the belt maintains the correct tension, preventing slippage and reducing wear on the belt and pulleys.

Cummins 6C8.3 and C8.3 G Engines

For the Cummins 6C8.3 and C8.3 G engines, the Belt Tensioner 3922900 is also suitable. These engines are typically used in a range of applications, from agricultural to industrial uses, and require a reliable tensioner to maintain optimal belt tension.

Cummins B3.9 G, B5.6 CM2670 B152B, B5.9 G, B5.9 GAS PLUS CM556, C GAS PLUS CM556, G5.9, G5.9 CM558, G8.3, ISB CM550, ISB5.9 CM2880 B110, ISB5.9 CM2880 B140, ISB5.9 CM2880 B149, ISB5.9G CM2180, ISC CM554, ISL CM554, QSB5.9 44 CM550, QSC8.3 CM554, and V903 Engines

The Belt Tensioner 3922900 is also compatible with a broader range of Cummins engines, including the B3.9 G, B5.6 CM2670 B152B, B5.9 G, B5.9 GAS PLUS CM556, C GAS PLUS CM556, G5.9, G5.9 CM558, G8.3, ISB CM550, ISB5.9 CM2880 B110, ISB5.9 CM2880 B140, ISB5.9 CM2880 B149, ISB5.9G CM2180, ISC CM554, ISL CM554, QSB5.9 44 CM550, QSC8.3 CM554, and V903 engines. These engines span various applications and are designed to deliver high performance and reliability. The Belt Tensioner 3922900 ensures that the serpentine belt remains properly tensioned, enhancing the efficiency and lifespan of the belt and associated components.

This compatibility ensures that the Belt Tensioner 3922900 can be used across a wide range of Cummins engines, providing a reliable solution for maintaining optimal belt tension.

Understanding the Role of Part 3922900 Belt Tensioner in Engine Systems

The part 3922900 Belt Tensioner is a component in maintaining the proper function of various engine systems. It ensures that the belts driving key components are kept at the correct tension, which is vital for the efficient operation of these systems.

Interaction with the Alternator and Its Drive System

The Belt Tensioner works in conjunction with the Alternator and its Drive System. As the engine operates, the Belt Tensioner maintains the necessary tension on the belt that connects the Alternator to the engine’s crankshaft. This ensures that the Alternator receives consistent power to generate electricity, which is essential for charging the battery and powering the vehicle’s electrical systems.

Coordination with the Water Pump Drive

Similarly, the Belt Tensioner plays a role in the Water Pump Drive system. The water pump relies on a belt to operate, circulating coolant through the engine to prevent overheating. The Belt Tensioner ensures that this belt remains taut, allowing the water pump to function effectively and maintain optimal engine temperature.

Integration with Mounting and Pulley Systems

The Belt Tensioner is also integral to the Mounting and Pulley Systems associated with both the Alternator and Water Pump. These systems rely on precise belt tension to operate smoothly. The Belt Tensioner adjusts to accommodate variations in belt wear and thermal expansion, ensuring that the pulleys spin efficiently without slippage or excessive wear.

Role in Service and Campaign Kits

When performing maintenance with a Service Kit or Campaign Kit, the Belt Tensioner is a component that often requires attention. These kits may include replacements or adjustments for the belt tensioner to ensure that all driven components continue to operate within their designed parameters after belt replacements or other maintenance procedures.

Conclusion

In summary, the Cummins 3922900 Belt Tensioner is a key player in the interplay between various engine components, ensuring that belts remain taut and systems operate efficiently. Its role in maintaining the integrity of the drive systems for the Alternator and Water Pump, among others, underscores its importance in engine maintenance and performance.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.