This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

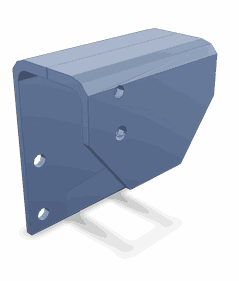

The Belt Tensioner Bracket, identified by part number 4937845, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This Cummins part plays a significant role in the operation of commercial trucks by ensuring the proper functioning of the belt tensioner system. Cummins, known for its robust and reliable engine solutions, designs this bracket to meet the demanding requirements of heavy-duty applications.

Function and Operation

The Belt Tensioner Bracket operates within the truck’s engine system by supporting the belt tensioner, which maintains the correct tension on the engine’s drive belts. Proper belt tension is vital for the efficient transfer of power from the engine to various components such as the alternator, water pump, and air conditioning compressor. The bracket ensures that the tensioner remains in the correct position and operates smoothly, which is crucial for the longevity and performance of the belts 1.

Key Features

The Belt Tensioner Bracket is designed with specific characteristics to enhance its durability and efficiency in heavy-duty applications. Constructed from high-strength materials, it is capable of withstanding the rigors of commercial truck operations. Its design includes precise mounting points and alignment features to ensure accurate installation and operation. The use of corrosion-resistant materials further enhances its longevity, making it suitable for various operating environments 2.

Benefits of Using a Belt Tensioner Bracket

Incorporating a Belt Tensioner Bracket into truck engines offers several advantages. It contributes to improved belt lifespan by ensuring consistent tension, which reduces wear and tear on the belts. This, in turn, leads to enhanced engine performance and reliability. Additionally, the bracket helps in minimizing the risk of belt slippage, which can cause engine components to malfunction 3.

Installation Process

Installing the Belt Tensioner Bracket requires careful attention to detail to ensure proper function. The process involves securing the bracket to the engine block using the provided mounting hardware. It is important to align the bracket correctly to ensure the tensioner operates within its designed parameters. Tools such as torque wrenches may be required to tighten the mounting bolts to the specified torque settings. Following the manufacturer’s instructions during installation is recommended to achieve optimal performance.

Maintenance and Troubleshooting

Regular maintenance of the Belt Tensioner Bracket is important to ensure its continued efficient operation. This includes checking for signs of wear or damage, ensuring that the mounting bolts are tight, and verifying that the tensioner moves freely within the bracket. Common issues may include worn mounting points or a malfunctioning tensioner, which can be addressed by inspecting and replacing worn components as necessary.

Safety Considerations

When working with the Belt Tensioner Bracket, it is important to observe safety guidelines to prevent injury and ensure the component’s proper function. This includes wearing appropriate personal protective equipment, ensuring the engine is off and cool before beginning work, and following all manufacturer-recommended procedures during installation and maintenance. Adhering to these safety practices helps maintain a safe working environment.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s product range includes engines for on-highway and off-highway applications, as well as components and systems that enhance engine performance and efficiency.

Role of Part 4937845 Belt Tensioner Bracket in Engine Systems

The 4937845 Belt Tensioner Bracket is an essential component in maintaining the proper function of various engine systems, particularly those involving the compressor and refrigerant cycle.

In systems where a compressor is utilized, such as in air conditioning or refrigeration units integrated within an engine, the Belt Tensioner Bracket ensures that the drive belt remains appropriately tensioned. This tension is vital for the efficient transfer of power from the engine to the compressor. Without adequate tension, the belt may slip, leading to inefficient compressor operation and potential system failure.

Additionally, in systems involving refrigerant, the compressor plays a significant role in circulating the refrigerant through the system. The Belt Tensioner Bracket, by maintaining consistent belt tension, supports the compressor’s ability to operate smoothly. This, in turn, ensures that the refrigerant is effectively cycled, maintaining the desired cooling effect and overall system performance.

The integration of the 4937845 Belt Tensioner Bracket within these engine systems highlights its importance in supporting both mechanical and thermal efficiency. Its role in sustaining the correct belt tension directly influences the operational integrity of the compressor and the effectiveness of the refrigerant cycle.

Conclusion

The Belt Tensioner Bracket part number 4937845, manufactured by Cummins, is a crucial component in the engine systems of various Cummins engines. Its role in maintaining proper belt tension is essential for the efficient operation and longevity of the engine. The bracket’s design, featuring high-strength and corrosion-resistant materials, ensures durability and reliability in heavy-duty applications. Regular maintenance and adherence to safety guidelines are recommended to ensure optimal performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.