This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

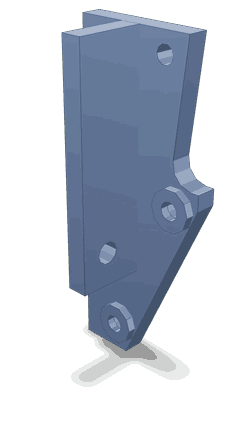

The Belt Tensioner Bracket, identified by Part #4913700, is a component manufactured by Cummins, a well-established name in the automotive industry. This Cummins part is integral to the operation of heavy-duty trucks, ensuring the efficient functioning of the engine’s belt system. Cummins, known for its robust and reliable parts, provides this bracket as part of its extensive range of components designed specifically for heavy-duty applications.

Function and Operation

The Belt Tensioner Bracket operates within the truck’s engine system by maintaining the appropriate tension on the engine’s belts. This tension is vital for the belts to function correctly, driving various engine components such as the alternator, water pump, and air conditioning compressor. The bracket achieves this by automatically adjusting the tension as the engine operates, compensating for wear and temperature changes that can affect belt performance 1.

Key Features

The design and material characteristics of the Belt Tensioner Bracket are tailored for durability and efficiency. Constructed from high-strength materials, it is engineered to withstand the harsh conditions typical of heavy-duty truck environments. The precision engineering ensures that it fits securely within the engine compartment, providing consistent and reliable belt tension. Its robust construction also contributes to the longevity of the belts it supports, reducing the frequency of replacements and maintenance 2.

Benefits of Using a Belt Tensioner Bracket

Incorporating a Belt Tensioner Bracket into truck engines offers several advantages. It contributes to an extended belt lifespan by maintaining optimal tension, which prevents premature wear and failure. Enhanced engine performance is another benefit, as properly tensioned belts ensure that all driven components operate efficiently. Additionally, the use of a tensioner bracket can lead to reduced maintenance requirements, as it minimizes the need for manual adjustments and replacements 3.

Installation Process

Installing the Belt Tensioner Bracket requires careful attention to detail and adherence to safety protocols. The process involves securing the bracket in its designated position within the engine compartment, ensuring it is aligned correctly with the belt and other components. Tools such as wrenches and screwdrivers may be necessary, depending on the specific model of the truck. Safety precautions, including disconnecting the battery and allowing the engine to cool, should be observed to prevent injury or damage during installation.

Common Issues and Troubleshooting

Typical problems associated with Belt Tensioner Brackets include misalignment, wear, and failure to maintain proper belt tension. These issues can often be identified through visual inspection or by observing symptoms such as unusual noises from the engine or a decrease in performance. Troubleshooting steps may involve realigning the bracket, tightening or replacing worn components, or in some cases, replacing the bracket itself. Regular maintenance and inspections can help prevent these issues.

Maintenance Tips

To ensure optimal performance of the Belt Tensioner Bracket, regular maintenance is recommended. This includes inspecting the bracket and associated belts for signs of wear or damage at routine intervals. Cleaning the bracket and its surrounding area can prevent the buildup of debris that might affect its operation. Replacement should be considered if significant wear is observed or if the bracket fails to maintain proper belt tension, ensuring the continued efficient operation of the engine.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. Its product range includes a variety of components for heavy-duty trucks, designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to excellence is reflected in its extensive portfolio of reliable and high-performance parts.

Belt Tensioner Bracket 4913700 Compatibility with Cummins Engines

The Belt Tensioner Bracket part number 4913700, manufactured by Cummins, is a critical component in maintaining the integrity and efficiency of the engine’s belt system. This part is designed to work seamlessly with several Cummins engine models, ensuring optimal performance and longevity.

K19 Engine Series

The K19 engine series is one of the prominent groups where the Belt Tensioner Bracket 4913700 is utilized. This series is known for its robust design and reliability, making it a popular choice in various industrial and commercial applications. The Belt Tensioner Bracket in this series plays a vital role in maintaining the correct tension of the engine belts, which is essential for the proper functioning of ancillary components such as the alternator, water pump, and air conditioning compressor.

Application in Other Cummins Engines

While the K19 series is a primary focus, the Belt Tensioner Bracket 4913700 is also compatible with other Cummins engine models. This compatibility extends to various engine groups where similar design and operational requirements are present. The bracket’s design ensures it fits snugly and securely, providing the necessary support and stability to the belt system.

Importance of Proper Installation

Proper installation of the Belt Tensioner Bracket 4913700 is crucial for the overall health of the engine. Incorrect installation can lead to belt slippage, increased wear on the belt and pulleys, and potential engine damage. Technicians should follow the manufacturer’s guidelines and use the appropriate tools to ensure the bracket is installed correctly.

Maintenance and Replacement

Regular maintenance of the Belt Tensioner Bracket is essential to prevent premature failure. Inspecting the bracket for signs of wear, corrosion, or damage is a routine part of engine maintenance. If any issues are detected, the bracket should be replaced promptly to maintain the engine’s performance and reliability.

Compatibility Summary

- K19 Engine Series: Designed to fit seamlessly, ensuring optimal belt tension and system efficiency.

- Other Cummins Engines: Compatible with various engine models where similar design and operational requirements are present.

By understanding the compatibility and importance of the Belt Tensioner Bracket 4913700, technicians and engine operators can ensure their engines run smoothly and efficiently.

Role of Part 4913700 Belt Tensioner Bracket in Engine Systems

The 4913700 Belt Tensioner Bracket is an integral component in maintaining the proper tension of the drive belts within an engine system. This ensures efficient power transmission from the engine to various auxiliary components.

Interaction with Mounting Components

The Belt Tensioner Bracket is securely mounted to the engine block or a designated mounting point. This mounting arrangement allows for the precise alignment and tensioning of the drive belts. The bracket’s sturdy construction ensures it can withstand the dynamic forces exerted by the belts during engine operation. Proper mounting of the tensioner bracket is essential for consistent belt tension, which in turn promotes reliable operation of connected components such as the alternator, water pump, and air conditioning compressor.

Coordination with Fan Drive System

In engine systems equipped with a fan drive, the Belt Tensioner Bracket plays a significant role in maintaining the correct tension of the belt that drives the cooling fan. The cooling fan is vital for dissipating heat from the engine, especially under high-load conditions or in hot weather. The tensioner bracket ensures that the belt remains taut, preventing slippage and ensuring that the fan operates at the required speed to maintain optimal engine temperature. This coordination is particularly important in systems where the fan drive is belt-operated, as inconsistent belt tension can lead to inefficient cooling and potential engine overheating.

Conclusion

The Belt Tensioner Bracket, part number 4913700, is a critical component in the maintenance and efficiency of heavy-duty truck engines. Its role in maintaining optimal belt tension ensures the reliable operation of various engine components, contributing to overall engine performance and longevity. Proper installation, regular maintenance, and understanding its compatibility with different Cummins engine models are essential for maximizing the benefits of this part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.