This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

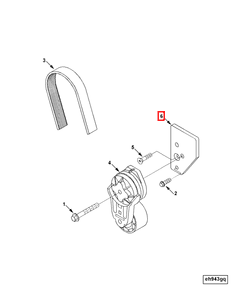

The Belt Tensioner Bracket, identified by Part #3929834, is a component manufactured by Cummins, a well-established name in the automotive industry. This part plays a significant role in the operation of heavy-duty trucks, ensuring the efficient functioning of the engine’s belt system. Cummins is renowned for its commitment to quality and innovation in the production of automotive parts, making this bracket a reliable choice for maintaining the performance of heavy-duty engines.

Function and Operation

The Belt Tensioner Bracket operates as a pivotal component within the truck’s engine system. Its primary role is to maintain the appropriate tension on the engine’s belts, which are essential for driving various engine accessories such as the alternator, water pump, and air conditioning compressor. By keeping the belts at the correct tension, the bracket ensures these components function efficiently, reducing the risk of belt slippage or breakage. The bracket achieves this by automatically adjusting the tension as the engine operates under different conditions.

Key Features

The design and material characteristics of the Belt Tensioner Bracket are tailored for heavy-duty applications. Constructed from high-strength materials, it is engineered to withstand the rigorous demands of heavy-duty truck engines. Its design incorporates features that enhance durability and efficiency, such as a robust mounting system and precision-machined surfaces for smooth operation. These characteristics ensure the bracket can endure the high stress and vibration levels typical in heavy-duty truck environments.

Benefits of Using a Belt Tensioner Bracket

Incorporating a Belt Tensioner Bracket into truck engines offers several advantages. One of the primary benefits is the improved lifespan of the engine belts. By maintaining optimal tension, the bracket reduces wear and tear on the belts, leading to longer intervals between replacements. Additionally, the use of a tensioner bracket can lead to reduced maintenance needs, as it minimizes the likelihood of belt-related issues. This results in lower overall maintenance costs and increased engine reliability.

Installation Process

Correct installation of the Belt Tensioner Bracket is crucial for ensuring optimal performance and safety. The process involves several steps: first, the engine must be prepared by removing the old bracket and any damaged belts. Next, the new bracket should be positioned according to the manufacturer’s specifications, ensuring it is aligned correctly with the engine’s pulleys. Once in place, the bracket is secured using the provided fasteners, and the belts are routed through the system. Finally, the tension should be adjusted to the manufacturer’s recommended levels, and the engine should be tested to confirm proper operation.

Common Issues and Troubleshooting

Typical problems associated with Belt Tensioner Brackets include improper tension, which can lead to belt slippage or damage, and bracket misalignment, which may cause increased wear on the belts or pulleys. To address these issues, it is important to regularly inspect the bracket and belts for signs of wear or damage. If improper tension is detected, the bracket should be adjusted or replaced as necessary. Misalignment issues may require re-positioning the bracket or addressing any underlying problems with the engine’s pulley system.

Maintenance Tips

To ensure the longevity and effectiveness of the Belt Tensioner Bracket, regular maintenance practices are recommended. This includes periodic inspection of the bracket and belts for signs of wear, ensuring the tension remains within the manufacturer’s specified range, and addressing any issues promptly. Additionally, keeping the engine clean and free of debris can help prevent damage to the bracket and belts. Following these maintenance tips can help extend the life of the bracket and ensure the engine operates efficiently.

Cummins: A Brief Overview

Cummins is a leading manufacturer in the automotive industry, known for its wide range of high-quality products. With a history spanning several decades, Cummins has established itself as a trusted provider of engines, components, and technologies for various applications, including heavy-duty trucks. The company’s commitment to quality is evident in its rigorous testing and quality control processes, ensuring that each product meets the highest standards of performance and reliability. Cummins continues to innovate, offering solutions that meet the evolving needs of the automotive industry.

Belt Tensioner Bracket 3929834 Compatibility with Cummins Engines

The Belt Tensioner Bracket part number 3929834, manufactured by Cummins, is designed to fit seamlessly with specific engine models. This bracket plays a crucial role in maintaining the proper tension of the engine’s serpentine belt, ensuring efficient operation and longevity of the belt and associated components.

Compatibility with 6C8.3 Engines

The 6C8.3 engine series benefits from the precise fit and robust construction of the 3929834 Belt Tensioner Bracket. This bracket is engineered to align perfectly with the engine’s design, providing a stable mounting point for the belt tensioner. Its compatibility ensures that the belt remains taut, reducing the risk of slippage and enhancing the overall performance of the engine.

Compatibility with C8.3 G Engines

Similarly, the C8.3 G engine series is another beneficiary of the 3929834 Belt Tensioner Bracket. This bracket is tailored to fit the specific layout and requirements of the C8.3 G engine, ensuring that it maintains the correct tension on the serpentine belt. Its design allows for easy installation and reliable operation, contributing to the engine’s efficiency and durability.

Grouping of Compatible Engines

The 3929834 Belt Tensioner Bracket is compatible with both the 6C8.3 and C8.3 G engines, making it a versatile choice for technicians and mechanics working with these engine types. Its design ensures that it fits snugly and functions optimally within the engine’s architecture, providing a reliable solution for maintaining belt tension.

Role of Part 3929834 Belt Tensioner Bracket in Engine Systems

The Part 3929834 Belt Tensioner Bracket is an integral component in maintaining the proper function of the alternator drive system. This bracket securely mounts the belt tensioner, which is responsible for keeping the drive belt at the correct tension.

When the engine is running, the drive belt transfers power from the crankshaft to the alternator. The alternator, in turn, generates electricity to power the vehicle’s electrical systems and recharge the battery.

The Belt Tensioner Bracket ensures that the belt remains taut, preventing slippage that could lead to inefficient power transfer and potential damage to the alternator or other driven components.

In summary, the Part 3929834 Belt Tensioner Bracket plays a significant role in the reliable operation of the alternator drive system by maintaining the necessary tension on the drive belt.

Conclusion

The Belt Tensioner Bracket, part number 3929834, is a critical component for the efficient operation of heavy-duty truck engines. Manufactured by Cummins, this part ensures the proper tension of the engine’s belts, contributing to the reliable performance of engine accessories. Its robust design and compatibility with specific Cummins engine models make it a valuable asset for maintaining engine efficiency and durability. Regular maintenance and proper installation are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.