This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

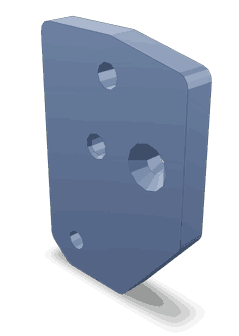

The Belt Tensioner Mounting Bracket, identified by Part #3285958, is a component manufactured by Cummins, a well-established name in the automotive industry, particularly known for its robust solutions in heavy-duty trucks. This Cummins part plays a significant role in the engine system of heavy-duty trucks, ensuring the efficient operation of the belt tensioner.

Function and Operation

The Belt Tensioner Mounting Bracket operates by securely holding the belt tensioner in place within the truck’s engine system. Its primary role is to maintain the proper tension of the belts that drive various engine components, such as the alternator, water pump, and air conditioning compressor. By keeping the belts at the correct tension, it ensures optimal performance and longevity of these components, reducing the risk of slippage or breakage 1.

Key Features

Designed with durability and efficiency in mind, the Belt Tensioner Mounting Bracket is constructed from high-quality materials that can withstand the demanding conditions of heavy-duty truck applications. Its design includes precise engineering to ensure a secure fit and stable operation under various engine loads and temperatures. This robustness contributes to the overall reliability of the engine system 2.

Benefits of Using the Belt Tensioner Mounting Bracket

Incorporating the Belt Tensioner Mounting Bracket into a truck’s engine system offers several advantages. It contributes to improved engine performance by ensuring that all driven components operate efficiently. Additionally, it reduces maintenance needs by minimizing the wear and tear on belts and related components. The enhanced reliability it provides can lead to fewer unexpected breakdowns, making it a valuable component for fleet operators 3.

Installation Process

Installing the Belt Tensioner Mounting Bracket requires careful attention to detail to ensure it is correctly positioned and secured. The process involves removing the old bracket (if applicable), aligning the new bracket with the mounting points on the engine, and securing it with the appropriate fasteners. Tools such as wrenches and possibly a torque wrench may be required to complete the installation. It is important to consult the vehicle’s service manual for specific instructions related to the truck model.

Common Issues and Troubleshooting

Typical problems associated with the Belt Tensioner Mounting Bracket may include loosening of the fasteners, wear on the bracket itself, or issues with the belt tensioner it supports. Troubleshooting steps may involve checking the tightness of the fasteners, inspecting the bracket for signs of wear or damage, and ensuring the belt tensioner is functioning correctly. Addressing these issues promptly can prevent more significant problems down the line.

Maintenance Tips

To ensure the longevity and optimal performance of the Belt Tensioner Mounting Bracket, regular maintenance practices are recommended. This includes periodic inspections for signs of wear or damage, ensuring all fasteners are tight, and checking the condition of the belts it supports. Keeping the engine bay clean can also contribute to the overall health of the engine system, including the belt tensioner and its mounting bracket.

Compatibility and Usage

The Belt Tensioner Mounting Bracket is designed for use in specific types of trucks and engine models. Its application is focused on heavy-duty truck scenarios where reliability and durability are paramount. Detailed information on compatibility and specific usage scenarios will be provided separately to ensure accurate installation and usage.

Manufacturer Overview - Cummins

Cummins is a renowned manufacturer in the automotive industry, with a strong reputation for producing high-quality engines and components for heavy-duty trucks. With a history of innovation and commitment to excellence, Cummins offers a wide range of products designed to meet the demanding needs of commercial and industrial applications. Their expertise in engine technology and component manufacturing makes them a trusted choice for fleet operators and maintenance professionals.

Belt Tensioner Mounting Bracket 3285958 Compatibility with Cummins Engines

The Belt Tensioner Mounting Bracket part number 3285958, manufactured by Cummins, is designed to fit a variety of Cummins engines. This bracket is a crucial component for maintaining the proper tension of the engine’s serpentine belt, ensuring optimal performance and longevity of the belt and associated components.

Compatible Engines

- 4B3.9

- 6B5.9

- B5.9 CM2670 B166C

- B5.9 GAS PLUS CM556

- QSB3.9 CM2880 B138

- QSB5.9 CM2880 B139

Grouping of Compatible Engines

The engines listed above can be grouped based on their model and configuration:

-

4B3.9 and QSB3.9 CM2880 B138: These engines share a similar base model, with the QSB3.9 being a more advanced version. The Belt Tensioner Mounting Bracket 3285958 fits both due to their comparable design and mounting requirements.

-

6B5.9 and QSB5.9 CM2880 B139: These engines, while differing in some specifications, share a common platform that necessitates the same mounting bracket for the belt tensioner. The QSB5.9 is an upgraded version of the 6B5.9, ensuring compatibility with the bracket.

-

B5.9 CM2670 B166C and B5.9 GAS PLUS CM556: These engines, despite their different fuel types (diesel vs. gas), are designed to use the same Belt Tensioner Mounting Bracket. The bracket’s design accommodates the slight variations in engine layout and mounting points.

By ensuring that the Belt Tensioner Mounting Bracket 3285958 is compatible with these engines, Cummins maintains a high standard of interchangeability and reliability across its engine lineup. This compatibility allows for easier maintenance and repair, as technicians can use a single part for multiple engine models, reducing inventory needs and simplifying the repair process.

Role of Part 3285958 Belt Tensioner Mounting Bracket in Engine Systems

The part 3285958 Belt Tensioner Mounting Bracket is an essential component in the assembly and operation of various engine systems, particularly those involving the alternator drive and belt tensioner.

Integration with Alternator Drive

In engine systems, the alternator drive relies on a consistent and optimal belt tension to function efficiently. The Belt Tensioner Mounting Bracket secures the belt tensioner in place, allowing it to apply the necessary force to the alternator drive belt. This ensures that the alternator receives the proper rotational speed and power transmission from the engine, which is vital for generating electricity to charge the battery and power the vehicle’s electrical systems.

Function in Belt Tensioner System

The Belt Tensioner Mounting Bracket plays a significant role in maintaining the correct tension on the engine’s accessory belts. By securely mounting the belt tensioner, it enables the tensioner to automatically adjust the belt’s tension as the engine operates. This is important because it prevents belt slippage, reduces wear and tear on both the belt and the pulleys, and ensures that all driven components, such as the alternator, water pump, and air conditioning compressor, operate smoothly and efficiently.

Overall System Efficiency

The proper installation and function of the Belt Tensioner Mounting Bracket contribute to the overall efficiency and reliability of the engine’s accessory drive system. It ensures that all components connected by the belt, including the alternator drive, receive consistent power transmission. This not only enhances the performance of individual components but also contributes to the longevity and stability of the entire engine system.

Conclusion

The Belt Tensioner Mounting Bracket part number 3285958, manufactured by Cummins, is a critical component in the engine systems of heavy-duty trucks. Its role in maintaining the proper tension of the engine’s accessory belts ensures the efficient operation of driven components such as the alternator, water pump, and air conditioning compressor. The bracket’s design, compatibility with various Cummins engines, and contribution to overall system efficiency make it a valuable asset for fleet operators and maintenance professionals.

-

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩ -

Taghavifar, Hamid and Mardani, Aref. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Huzij, Robert, Spano, Angelo, and Bennett, Sean. Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.