This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

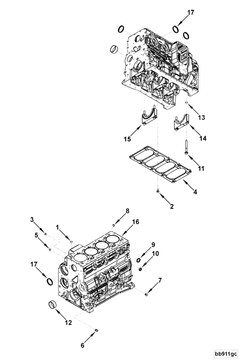

The Cummins 5314776 Main Bearing Cap is a critical component in the engine assembly of heavy-duty trucks. It secures the main bearings, which support the crankshaft, ensuring smooth and efficient engine operation by maintaining proper alignment and reducing friction between the crankshaft and the engine block.

Function and Operation

The main bearing cap provides a stable foundation for the main bearings, which support the crankshaft. This setup allows the crankshaft to rotate with minimal friction. The cap is bolted to the engine block, creating a secure environment for the bearings to operate. This contributes to the overall stability and performance of the engine, ensuring smooth operation under various load conditions 1.

Design and Construction

The Cummins 5314776 Main Bearing Cap is engineered with precision to meet the demanding requirements of heavy-duty applications. It is typically constructed from high-strength alloy steel, providing durability and resistance to wear. The manufacturing process involves precise machining to ensure a perfect fit with the engine block and correct alignment with the crankshaft. Unique design elements, such as oil passages and relief grooves, are incorporated to enhance lubrication and cooling, further improving the cap’s performance and longevity 2.

Installation Process

Proper installation of the Cummins 5314776 Main Bearing Cap is crucial for optimal engine performance. The process begins with thorough cleaning of the engine block and the cap to remove any debris or old gasket material. The cap is then aligned with the main bearing journal on the crankshaft and positioned in the engine block. Using the appropriate tools, the cap is bolted into place, with torque specifications carefully followed to ensure a secure fit without over-tightening. Alignment procedures, such as using a straightedge to check for proper positioning, are performed to guarantee that the crankshaft is correctly supported 3.

Maintenance and Inspection

Routine maintenance and inspection of the main bearing cap are necessary to ensure continued engine performance. Regular checks should include visual inspections for signs of wear, such as scoring or pitting on the cap surface, and verifying that all bolts are securely tightened. Recommended inspection intervals vary depending on the operating conditions but generally align with major engine service intervals. Addressing common issues promptly, such as replacing worn bearings or tightening loose bolts, helps maintain the integrity of the engine assembly 4.

Troubleshooting Common Issues

Common problems associated with the main bearing cap include bearing failure, oil leaks, and misalignment. Bearing failure can often be attributed to inadequate lubrication or excessive wear, while oil leaks may indicate damaged gaskets or improper sealing. Misalignment issues can arise from incorrect installation or wear on the cap or crankshaft journal. Preventive measures, such as regular lubrication checks, proper torque during installation, and timely replacements of worn components, can help avoid these issues 5.

Benefits of Using Cummins Main Bearing Caps

Choosing Cummins main bearing caps offers several advantages. These caps are designed for durability and reliability, ensuring long-term performance in heavy-duty applications. They are engineered to be compatible with Cummins engines, providing a seamless fit and optimal function. Additionally, Cummins main bearing caps may offer performance enhancements, such as improved lubrication distribution and reduced friction, contributing to overall engine efficiency.

Cummins Company Overview

Cummins Inc. is a renowned leader in the automotive industry, known for its high-quality engine components for commercial vehicles. With a rich history of innovation and excellence, Cummins has established a reputation for producing reliable and durable parts that meet the rigorous demands of heavy-duty applications. The company’s commitment to quality and performance is evident in its extensive range of engine components, including the Cummins 5314776 Main Bearing Cap.

Cummins Main Bearing Cap 5314776 Compatibility

The Cummins part number 5314776, which is a Main Bearing Cap, is designed to fit a variety of Cummins engine models. This part is integral to the engine’s operation, providing a stable and secure connection between the crankshaft and the engine block. Below is a detailed overview of the engine models compatible with this main bearing cap.

Cummins B-Series Engines

- 6B5.9

- B4.5 CM2350 B129B

- B5.6 CM2670 B152B

- B5.9 GAS PLUS CM556

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH6.0 B125

Cummins D-Series Engines

- D4.0 CM2620 D103B

Cummins F-Series Engines

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

Cummins ISB and ISBE Engines

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB4.5 CM2350 B104

- ISB5.9 CM2880 B110

- ISB5.9G CM2180

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

- ISBE CM2150

- ISBE CM800

This main bearing cap is engineered to ensure compatibility across these diverse engine models, providing a reliable and durable solution for maintaining the structural integrity of the engine.

Role of Part 5314776 Main Bearing Cap in Engine Systems

The part 5314776 Main Bearing Cap is an integral component in the assembly and operation of various engine systems. When integrated with the Cylinder Block, it secures the main bearings which support the crankshaft, ensuring smooth rotation and minimizing friction. This is essential for the efficient transfer of power from the crankshaft to the rest of the engine components.

In a Cylinder Block Kit, the main bearing cap works in conjunction with other components to provide a robust foundation for the engine’s internal mechanisms. It helps in maintaining the precise alignment of the crankshaft, which is vital for the engine’s balance and performance.

Within a Long Block assembly, which includes the cylinder block, crankshaft, pistons, and other essential components, the main bearing cap plays a significant role in ensuring the structural integrity and operational efficiency of the engine. It supports the crankshaft under high loads and varying speeds, contributing to the engine’s durability and reliability.

In a Short Block Kit, which typically consists of the cylinder block, crankshaft, pistons, and main bearings, the main bearing cap is key to securing the crankshaft in place. This ensures that the crankshaft operates within specified tolerances, which is important for the engine’s overall performance and longevity.

Overall, the part 5314776 Main Bearing Cap is a fundamental component that enhances the functionality and reliability of engine systems by providing essential support and stability to the crankshaft.

Conclusion

The Cummins 5314776 Main Bearing Cap is a vital component in the engine assembly of heavy-duty trucks. Its precise design, robust construction, and proper installation are crucial for ensuring the smooth and efficient operation of the engine. Regular maintenance and inspection, along with addressing common issues promptly, help maintain the integrity and performance of the engine. Choosing Cummins main bearing caps offers advantages in durability, reliability, and performance enhancements, making them a preferred choice for heavy-duty applications.

-

Automotive Emissions Regulations and Exhaust Aftertreatment Systems, John Kasab and Andrea Strzelec, SAE International, 2020.

↩ -

Modelling Diesel Combustion, P A Lakshminarayanan and Yogesh V Aghav, Springer Science, 2010.

↩ -

Transmissions and Drivetrain Design, Michael Hilgers, Springer Vieweg, 2022.

↩ -

Heavy Duty Truck Systems, Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011.

↩ -

Fault Code Troubleshooting Manual, Cummins Inc., Bulletin Number 5676916.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.