4309174

Connecting Rod Bearing Kit

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

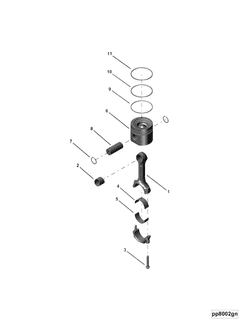

The Cummins 4309174 Connecting Rod Bearing Kit is engineered for commercial trucks, aiming to enhance engine operation and longevity. This part is essential for maintaining the integrity of the engine’s moving components, ensuring smooth and efficient performance.

Basic Concepts of Connecting Rod Bearing Kits

Connecting rod bearings are positioned between the crankshaft and connecting rods in an engine. They facilitate the smooth rotation of the crankshaft as it interacts with the pistons. By reducing friction and wear between these moving parts, connecting rod bearings contribute to the overall efficiency and durability of the engine 1.

Role of the 4309174 Connecting Rod Bearing Kit

The Cummins 4309174 Connecting Rod Bearing Kit is integral to the engine assembly. It interfaces directly with the crankshaft and connecting rods, minimizing friction and wear. This interaction is vital for maintaining the precision and reliability of the engine’s operation, directly influencing engine performance and longevity 2.

Key Features

The Cummins 4309174 Connecting Rod Bearing Kit is characterized by its high-quality material composition and precise design specifications. These features are intended to enhance its performance and durability. The kit is engineered to meet the demanding requirements of commercial truck engines, ensuring it can withstand high loads and operating conditions 3.

Benefits

Utilizing the Cummins 4309174 Connecting Rod Bearing Kit in an engine assembly can lead to improved engine efficiency through reduced friction. This reduction in friction can contribute to enhanced durability of the engine components. Additionally, the kit’s design may offer potential cost savings for fleet operators by extending the maintenance intervals and reducing the likelihood of engine failures.

Troubleshooting and Maintenance

Common issues with connecting rod bearings can include excessive wear, noise, or failure due to inadequate lubrication or contamination. Diagnostic procedures for these issues may involve visual inspection, measurement of clearances, and analysis of oil samples. Regular maintenance practices, such as proper lubrication and timely replacement of worn components, are important for ensuring the optimal performance and longevity of the 4309174 Connecting Rod Bearing Kit.

Interaction with Other Components

- Crankshaft: The connecting rod bearings, included in the 4309174 kit, interface directly with the crankshaft. They provide a low-friction surface that allows the crankshaft to rotate with minimal resistance, which is vital for the engine’s performance and longevity.

- Connecting Rods: These bearings are press-fit into the small end of the connecting rods. Their primary function is to reduce friction between the connecting rod and the crankshaft journal, thereby enhancing the overall efficiency of the engine.

- Pistons: Although not a direct interface, the health of the connecting rod bearings indirectly affects the pistons. Smooth operation of the bearings ensures that the connecting rods transmit piston motion to the crankshaft effectively, maintaining consistent engine performance.

- Oil Supply System: Proper lubrication is essential for the functioning of the connecting rod bearings. The oil supply system, including oil pumps and galleries, must deliver adequate lubrication to these bearings to prevent wear and ensure smooth operation.

- Main Bearings: While main bearings support the crankshaft in the engine block, the connecting rod bearings support the crankshaft at the connecting rod journals. Both types of bearings work in tandem to maintain the crankshaft’s alignment and operational integrity.

- Engine Block: The engine block houses the crankshaft and provides the structural framework for the entire engine. The condition of the connecting rod bearings impacts the overall stability and performance of the engine block.

Functional Significance

The 4309174 connecting rod bearing kit plays a significant role in the overhaul process by ensuring that all moving parts within the engine can operate with minimal friction and maximum efficiency. This, in turn, contributes to the engine’s reliability, performance, and longevity. The kit’s bearings are designed to withstand high loads and temperatures, making them a vital component in the overhaul kit for maintaining engine health.

Components of Cummins Kit 4309174: Connecting Rod Bearing Kit

The Cummins Kit 4309174, known as the Connecting Rod Bearing Kit, comprises essential components designed to ensure the smooth operation and longevity of engine components. Central to this kit are the connecting rod bearings, specifically identified by the part numbers 2899854 and 2899855.

These bearings play a crucial role within the kit by providing a low-friction interface between the connecting rod and the crankshaft journal. Their primary function is to facilitate the rotational movement of the connecting rod, which is pivotal for the efficient transfer of power from the piston to the crankshaft.

Each bearing is meticulously engineered to withstand the high loads and temperatures encountered within the engine environment. The inclusion of two distinct part numbers (2899854 and 2899855) suggests that these bearings may have slight variations in specifications or application, ensuring that the kit can accommodate different engine configurations or maintenance requirements.

The presence of these bearings in the kit underscores Cummins’ commitment to providing comprehensive solutions for engine maintenance, enabling technicians to perform precise and effective repairs or upgrades.

Conclusion

The Cummins 4309174 Connecting Rod Bearing Kit is a vital component for maintaining the efficiency and longevity of commercial truck engines. Its high-quality materials, precise design, and integration with other engine components ensure smooth operation and reduced maintenance costs. Regular maintenance and proper lubrication are essential for maximizing the benefits of this Cummins part.

-

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Hilgers, M. (2022). Transmissions and Drivetrain Design. Springer Vieweg.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.