This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

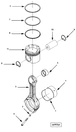

The Cummins 3636499 Connecting Rod Bearing is a component designed for use in heavy-duty truck engines. Its purpose is to facilitate smooth operation between the connecting rod and the crankshaft. This bearing plays a role in the engine’s cooling system by ensuring the efficient and reliable performance of the engine 1.

Basic Concepts of Connecting Rod Bearings

Connecting rod bearings are components found in internal combustion engines. They function by providing a low-friction interface between the connecting rod and the crankshaft. This allows for the efficient transfer of force from the piston to the crankshaft, enabling the engine’s moving parts to operate smoothly 2.

Role of the 3636499 Connecting Rod Bearing in Truck Operation

This Cummins part supports the interaction between the connecting rod and the crankshaft in a truck engine. By reducing friction and wear between these components, it contributes to the overall efficiency and durability of the engine. This bearing ensures that the force generated by the piston’s movement is effectively transmitted to the crankshaft, which is vital for the engine’s operation 3.

Key Features of the 3636499 Connecting Rod Bearing

The 3636499 is characterized by its material composition and design. It is constructed from high-quality materials that offer durability and resistance to wear. The design of the bearing includes features that enhance its performance, such as precise tolerances and a smooth surface finish. These attributes contribute to its ability to withstand the demanding conditions within a heavy-duty truck engine 1.

Benefits of Using the 3636499 Connecting Rod Bearing

Using this part can lead to improved engine efficiency, reduced friction, and enhanced longevity of engine components. Its design and material properties allow it to operate effectively under high loads and temperatures, contributing to the overall reliability and performance of the engine 2.

Installation and Maintenance Guidelines

When installing the 3636499 Connecting Rod Bearing, it is important to follow preparatory steps to ensure a proper fit and function. This includes cleaning the bearing surfaces and inspecting the crankshaft journal for any imperfections. Torque specifications should be adhered to during installation to ensure the bearing is securely in place. Regular maintenance practices, such as oil changes and inspections, are recommended to prolong the life of the bearing 3.

Troubleshooting Common Issues

Common problems that may arise with connecting rod bearings include wear, noise, or failure. These issues can often be diagnosed through careful inspection and analysis of the engine’s performance. Troubleshooting steps may involve checking the bearing clearance, inspecting the crankshaft journal, and assessing the lubrication system to identify and address the root cause of the problem 1.

Regular Maintenance Practices

To maintain the 3636499 Connecting Rod Bearing, regular oil changes are recommended to ensure proper lubrication. Inspection procedures should be conducted to check for signs of wear or damage, such as increased clearance or unusual noise. Addressing these issues promptly can help prevent more significant problems and extend the life of the bearing 2.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry. With a history of innovation and commitment to quality, Cummins offers a wide range of products designed to meet the demands of various applications. The company’s reputation for reliability and performance is built on its dedication to engineering excellence and customer satisfaction 3.

Conclusion

The Cummins 3636499 Connecting Rod Bearing is a critical component in heavy-duty truck engines, designed to ensure smooth operation and efficient force transfer between the connecting rod and the crankshaft. Its high-quality material composition and precise design contribute to the engine’s overall efficiency, durability, and performance. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential to maximize the bearing’s lifespan and ensure the engine’s reliable operation.

-

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ ↩ ↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩ ↩ ↩ -

Klyde, Michael, and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.