3636495

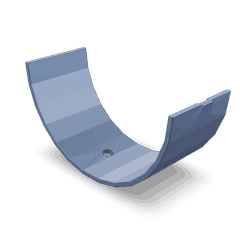

Connecting Rod Bearing

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3636495 Connecting Rod Bearing Shell is a component designed to facilitate the smooth operation of heavy-duty truck engines. Its purpose is to reduce friction between the connecting rod and the crankshaft journal, thereby contributing to the efficient and reliable performance of the engine. Understanding its function and significance is key to maintaining the optimal operation of heavy-duty trucks 1.

Basic Concepts of Connecting Rod Bearing Shells

Connecting rod bearing shells are components that play a role in the engine by providing a low-friction surface between the connecting rod and the crankshaft journal. These shells contribute to the overall performance and durability of the engine by ensuring that the reciprocating motion of the piston is efficiently translated into rotational motion of the crankshaft. They are typically made from materials that can withstand high pressures and temperatures, ensuring longevity and reliability 2.

Role of the 3636495 Connecting Rod Bearing Shell in Truck Operation

This Cummins part plays a specific role in the operation of a truck engine by facilitating the smooth interaction between the connecting rod and the crankshaft journal. This interaction is vital for the efficient conversion of the linear motion of the piston into rotational motion, which powers the truck. The bearing shell’s design allows for minimal friction, which is crucial for the engine’s performance and durability 3.

Key Features of the 3636495 Connecting Rod Bearing Shell

This part is characterized by its material composition, which typically includes a combination of metals and alloys designed to withstand the high pressures and temperatures within an engine. Its design specifications are tailored to fit precisely within the engine’s connecting rod and crankshaft journal, ensuring optimal performance. Unique attributes may include enhanced lubrication channels or a specialized coating to further reduce friction and wear 4.

Benefits of Using the 3636495 Connecting Rod Bearing Shell

Using this part is associated with several benefits, including improved engine efficiency due to reduced friction, which can lead to better fuel economy. Additionally, the shell’s design contributes to enhanced durability, helping to protect the engine from wear and tear over time. These factors combined can result in a more reliable and longer-lasting engine performance 5.

Installation and Maintenance

Proper installation of this part involves following recommended procedures and using appropriate tools to ensure a secure fit within the engine. Maintenance tips to ensure longevity and optimal performance include regular inspection for signs of wear or damage, proper lubrication, and adherence to manufacturer guidelines for replacement intervals. These practices help maintain the shell’s effectiveness and contribute to the overall health of the engine .

Troubleshooting Common Issues

Common issues that may arise with connecting rod bearing shells include wear and tear or improper installation. Symptoms of these issues can manifest as increased engine noise, reduced performance, or even engine failure in severe cases. Troubleshooting steps may involve inspecting the shell for signs of damage, ensuring proper lubrication, and verifying that the shell is correctly installed. Addressing these issues promptly can help prevent further damage and maintain engine efficiency .

Performance Enhancements

The 3636495 Connecting Rod Bearing Shell contributes to overall engine performance by ensuring smooth operation between the connecting rod and crankshaft journal. This can lead to potential improvements in power output and fuel efficiency, as reduced friction allows for more efficient energy transfer within the engine. Additionally, the shell’s durability helps maintain consistent performance over time, supporting the engine’s reliability .

Compatibility and Applications

This part is designed for use with specific Cummins engine models, ensuring compatibility and optimal performance. Its applications extend to various types of heavy-duty trucks, where it plays a vital role in engine operation. Understanding the shell’s compatibility and applications is important for selecting the appropriate component for engine maintenance or upgrade .

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive industry, known for its wide range of products, including engines and components for heavy-duty trucks. With a strong reputation for quality and reliability, Cummins has been a leader in providing solutions that enhance the performance and efficiency of vehicles. The company’s commitment to innovation and customer satisfaction has made it a preferred choice for professionals in the automotive sector.

Connecting Rod Bearing Shell (Part 3636495) Compatibility with Cummins Engines

The Connecting Rod Bearing Shell (Part 3636495) is a critical component in ensuring the smooth operation of various Cummins engines. This part is designed to fit seamlessly within the engine architecture, providing a stable and reliable interface between the connecting rod and the crankshaft. Here is a detailed look at its compatibility across different Cummins engine models:

QSK45 CM500 and QSK60 CM500

The QSK45 CM500 and QSK60 CM500 engines share a similar design philosophy, which allows the Connecting Rod Bearing Shell (Part 3636495) to be used interchangeably in both models. This commonality in design ensures that the bearing shell fits snugly within the engine’s architecture, providing the necessary support and lubrication to the connecting rod. The precision engineering of this part ensures minimal wear and tear, contributing to the longevity and efficiency of these engines.

QSK60 CM850 MCRS

The QSK60 CM850 MCRS engine, while part of the same family, incorporates more advanced features and technologies. The Connecting Rod Bearing Shell (Part 3636495) in this engine model is designed to handle higher loads and stresses, thanks to its robust construction and material quality. This bearing shell is engineered to provide superior performance, ensuring that the engine operates at peak efficiency even under demanding conditions.

QSK60G

The QSK60G engine represents a more specialized application within the Cummins lineup. The Connecting Rod Bearing Shell (Part 3636495) in this engine is tailored to meet the specific requirements of its design. This part is crafted to provide optimal performance, durability, and reliability, ensuring that the engine can handle the unique stresses and demands placed upon it.

Summary

The Connecting Rod Bearing Shell (Part 3636495) is a versatile and essential component that fits seamlessly into various Cummins engine models, including the QSK45 CM500, QSK60 CM500, QSK60 CM850 MCRS, and QSK60G. Its design ensures compatibility and performance across these engines, contributing to their overall efficiency and longevity.

Role of Part 3636495 Connecting Rod Bearing Shell in Engine Systems

This part is an essential component within the engine system, facilitating smooth and efficient operation of several key elements.

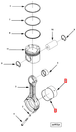

Interaction with the Engine Piston Kit and Piston

The Connecting Rod Bearing Shell interfaces directly with the engine piston kit and piston. It is positioned between the crankshaft and the connecting rod, allowing for the smooth transfer of motion from the piston to the crankshaft. This bearing shell reduces friction and wear, ensuring that the piston’s reciprocating motion is converted into rotational force effectively.

Contribution to the Engine Top Level Assembly Piston

In the engine top level assembly piston, the Connecting Rod Bearing Shell plays a significant role in maintaining the integrity and performance of the assembly. By providing a low-friction surface, it helps in minimizing energy loss and enhancing the overall efficiency of the piston’s movement.

Relationship with the Camshaft and Cylinder Head

Although the camshaft and cylinder head operate in a different part of the engine, the efficient operation of the Connecting Rod Bearing Shell indirectly influences their performance. A well-functioning bearing shell ensures that the piston moves smoothly, which in turn allows the camshaft to operate the valves at the cylinder head with precision timing. This synchronization is vital for optimal combustion and engine performance.

Impact on Injector Performance

The injector’s role in delivering fuel into the combustion chamber is also supported by the efficient operation of the Connecting Rod Bearing Shell. Smooth piston movement, facilitated by the bearing shell, ensures consistent engine RPMs, which are crucial for the injector to deliver fuel at the right time and in the right quantity. This consistency leads to better fuel atomization and combustion, ultimately enhancing engine performance.

Design and Alternative Parts

In engine design, the Connecting Rod Bearing Shell is often considered alongside alternative parts that might offer different performance characteristics. Engineers may opt for different materials or designs based on the specific requirements of the engine, such as higher load-bearing capacity or reduced friction. The choice of bearing shell can significantly influence the engine’s durability, efficiency, and overall performance.

Conclusion

The Cummins 3636495 Connecting Rod Bearing Shell is a critical component in the efficient operation of heavy-duty truck engines. Its role in reducing friction, enhancing durability, and ensuring smooth interaction between the connecting rod and crankshaft journal is vital for the engine’s performance and longevity. Proper installation, maintenance, and understanding of its compatibility with various Cummins engine models are essential for optimal engine operation.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

Diesel Engines, A. J. Wharton, Butterworth-Heinemann Ltd, 1991.

↩ -

Diesel Engine System Design, Qianfan Xin, Woodhead Publishing, 2011.

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

X12 CM2670 X121B, Service Manual (5504455).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.