This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3636432 Bearing Lock Washer is a critical component in commercial trucks, designed to enhance the efficiency and reliability of the vehicle’s mechanical systems. Understanding its function and importance is essential for maintaining the mechanical integrity of commercial trucks.

Basic Concepts of Bearing Lock Washers

A bearing lock washer is a mechanical component that secures bearings in place, preventing them from shifting or loosening during operation. This stability is crucial for the smooth operation of mechanical systems, as it maintains alignment and reduces the risk of wear and damage 1.

Purpose of the 3636432 Bearing Lock Washer

This Cummins part plays a role in securing the bearing within the assembly of a truck. By keeping the bearing in the correct position, it contributes to the efficient transfer of load and reduces friction. This component is integral to the bearing system, ensuring that the bearing operates within its designed parameters, thereby enhancing the performance and longevity of the truck’s mechanical components 2.

Key Features

The 3636432 Bearing Lock Washer is characterized by its material composition, typically made from high-strength steel to withstand the rigors of commercial truck operation. Its design includes specific attributes such as a precise fit and a locking mechanism that ensures the bearing remains securely in place. These features contribute to the washer’s ability to enhance the performance and durability of the bearing system 3.

Benefits

The use of the 3636432 Bearing Lock Washer offers several benefits. It provides improved stability to the bearing assembly, reducing the likelihood of misalignment. This stability contributes to reduced wear on the bearing and associated components, leading to enhanced durability of the system. Additionally, by securing the bearing in place, it helps maintain optimal performance of the truck’s mechanical systems 4.

Installation Process

Proper installation of the 3636432 Bearing Lock Washer involves several steps to ensure it fits correctly and functions as intended. The process includes cleaning the bearing and the area where the washer will be installed, placing the washer over the bearing, and then securing the bearing within the assembly. Tools such as a bearing press may be required to ensure the bearing is correctly seated. Following the manufacturer’s guidelines for installation is recommended to ensure the component is fitted correctly.

Troubleshooting Common Issues

Common issues with bearing lock washers may include loosening of the bearing or damage to the washer. Troubleshooting these problems involves inspecting the washer and bearing for signs of wear or damage, ensuring the washer is correctly installed, and replacing any components that show signs of failure. Regular inspection and maintenance can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

Regular maintenance of the 3636432 Bearing Lock Washer is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the component to remove any debris that may affect its function, and replacing the washer if it shows signs of failure. Adhering to recommended inspection intervals and replacement guidelines can help maintain the efficiency and reliability of the bearing system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s products, including the 3636432 Bearing Lock Washer, are designed with a focus on durability, performance, and reliability, reflecting Cummins’ dedication to excellence in the field of commercial vehicle components.

Role of Part 3636432 Bearing Lock Washer in Engine Systems

In the context of engine systems, the 3636432 Bearing Lock Washer is instrumental in ensuring the stability and efficiency of various components.

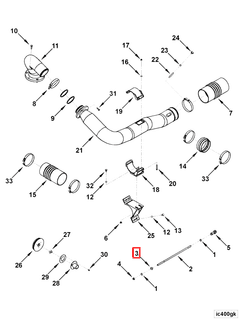

Charge Air Cooler Kit

Within the charge air cooler kit, the 3636432 Bearing Lock Washer is utilized to secure the bearings that support the rotating components. This ensures that the bearings remain in place under the high-pressure conditions typical in charge air coolers, thereby maintaining optimal airflow and cooling efficiency.

Connection

For connections in engine systems, the 3636432 Bearing Lock Washer plays a significant role in stabilizing the bearings at joints and pivot points. This stability is essential for smooth operation and reduces the likelihood of wear and tear at these critical junctures.

Air Intake

In the air intake system, the 3636432 Bearing Lock Washer is employed to secure bearings in components such as turbines or fans. This ensures that these parts can spin freely while remaining firmly in place, which is vital for consistent air flow into the engine.

Tie Rod

In steering systems, specifically tie rods, the 3636432 Bearing Lock Washer helps to keep the bearings aligned and secure. This alignment is important for precise steering control and reduces the risk of misalignment that could lead to uneven tire wear or handling issues.

Conclusion

Overall, the 3636432 Bearing Lock Washer is a small yet significant component that enhances the reliability and performance of various engine and steering system components. Its role in securing bearings and maintaining alignment is crucial for the efficient operation of commercial trucks.

-

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles (SAE International, 2014).

↩ -

Rolf Isermann, Combustion Engine Diagnosis (Springer Vieweg, 2017).

↩ -

Paul Dempsey, Troubleshooting and Repairing Diesel Engines (McGraw-Hill, 2008).

↩ -

John Dixon, Modern Diesel Technology Preventive Maintenance and Inspection (Delmar Cengage Learning, 2010).

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.